More than ever the partner for sheet and tube machining in all formats

Participation and acquisition accelerate evolution

At Shapes Group, they prefer to work for several SMEs rather than a few multinationals. This supplier for metal parts and (sub)assemblies with sites in Kuurne and Gullegem offers everything under one roof: punching, laser cutting, bending, turning, milling, welding and painting of steel, stainless steel and aluminum, as well as assembly of mechanical components. Through a participation in the powder coating company Poedr. and the acquisition of Advanced Tube Technology (ATT), specialist in tube laser work, new operations were recently added to the portfolio of this one-stop shop.

Added value

Flexibility, delivery reliability and quality are the assets that make Shapes Group a successful partner for companies in Flanders looking for metal parts and (sub)assemblies.

"Under the motto 'We Shape Your Ideas,' we want to distinguish ourselves from other suppliers by completely unburdening customers and offering added value: from design (via co-engineering) to the finished piece with or without surface treatment, and even packaging," says managing director Dirk Haerinck. "This is only possible thanks to a rock-solid team of 140 loyal employees and state-of-the-art machinery. We also have the necessary certificates, including the ISO 9001:2015 label and the ISO 3834-2 welding quality system with product standards EN 15085-2/CL1 for the rail industry and EN 1090-2/3 for structural structures. A tripling of turnover and workforce over a ten-year period shows that we made the right choices."

Machinery and operations

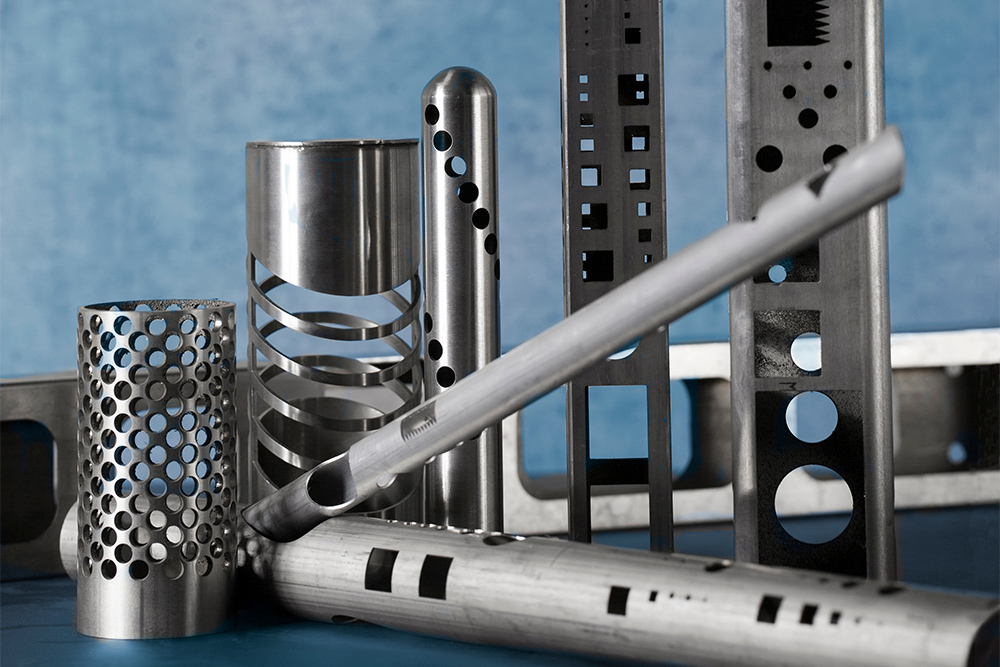

Customers can come to Shapes Group for prototypes, piecework and small and medium series, all custom-made. For this purpose, the company has a fully automated machine park, controlled from a plate warehouse with 700 locations for plates up to 3,000 mm and one with 45 locations for base material up to 6,000 mm. Production includes eight lathes, sixteen milling centers, one punch press, six laser cutting machines for pieces up to 3,000 mm wide and 18,000 mm long, as well as six bending machines for machining parts with lengths up to 8,000 mm, supplemented by a bending robot up to 5,000 mm. In the welding shop, seven modern welding robots are combined with a group of certified MIG/MAG and TIG welders. The in-house wet-painting installation and a measuring room with 3D measuring bench are additional assets.

"In recent years we have invested heavily to keep that machinery up to date. For example, we replaced our 6kW fiber laser with a system with a 20 kW fiber laser source, allowing us to machine sheets with thicknesses up to 40 mm and even more. We coupled this machine with an automatic MOVit tower warehouse for sheets up to 6,000 mm and a unique system for unloading and efficiently sorting cut pieces. Thanks to the new 10 kW large-format laser cutting machine, we can also cut extra-large plates up to as much as 18,000 mm. This machine is also equipped with an advanced bevel cutting head that allows plates to be cut at an angle of up to 45°, and in all directions," explains the business manager. "Also in the coming years, state-of-the-art machines with automation and robotization will be purchased to support our 'hands' on the shop floor. Furthermore, efforts will also be made to digitize business processes, from quotation and ordering to production and delivery."

Participation and acquisition for rapid growth

At Shapes Group, they continue to look for opportunities to expand their offerings. At the site in Kuurne, there is still 10,000 m² of space for further expansion, and an additional 8,000 m² of land was purchased last year in Gullegem. The company is also focusing more and more on the assembly of mechanical components. The customer does not receive individual plates, but the complete casing of his machines, after which he can start more quickly with the finishing, wiring and assembly of accessories. Here and there there was still a "blind spot," particularly machining operations that had to be outsourced, including powder coating and tube laser work.

"There are two ways to expand the offer: the so-called long step by investing in space, machines and people, or the shorter step by taking advantage of opportunities to participate in companies or take over activities," concludes Dirk Haerinck. "Through a fifty percent stake in growth company Poedr. of Wielsbeke, we can now offer powder-coated parts. We also took over Advanced Tube Technologies (ATT), a company in Roeselare that specializes in laser cutting tubes and profiles. This allows us to offer 'the full picture' more than ever before."