When plastic becomes oil again: igus invests in chemical recycling pioneer

Cat-HTR technology developed by German scientists recovers raw materials from plastic waste in 20 minutes

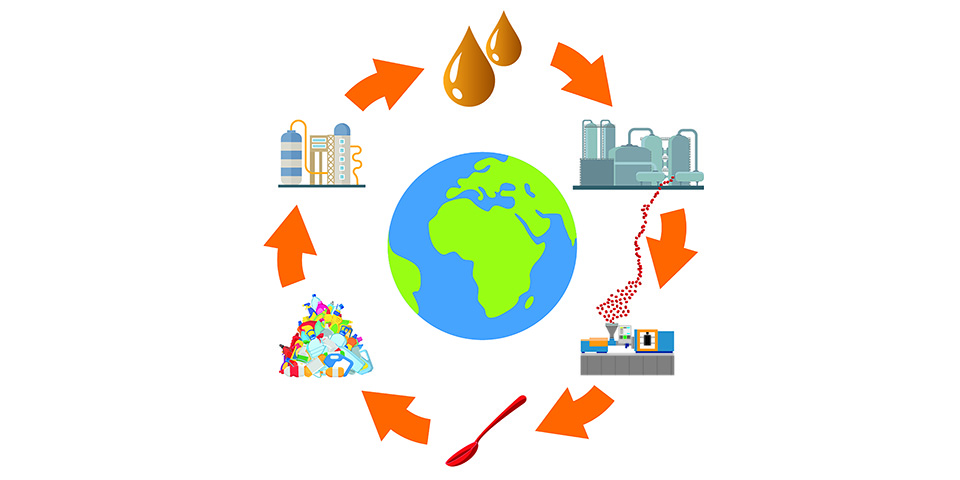

Renewable, sustainable and waste-reducing: these are the goals behind the Cat-HTR (Catalytic Hydrothermal Reactor) technology. It can be used to recycle plastic waste within 20 minutes. The oil obtained can be reused to produce new polymer products. To boost the circular economy of plastics, igus has now invested €4.7 million in a company that plans to launch the first commercial Cat-HTR plant.

Eight million metric tons of plastic waste is dumped into the world's oceans every year[1]. These wasted resources are worth about USD 80 billion[2]. The problem so far is that most plastic is incinerated and only 14 percent is recycled[3]. Plastic recycling is also an important issue for igus. In terms of traditional recycling - grinding and reusing plastic - igus took a bold step last October by introducing its new chainge program. The company takes back cable beads after the end of a machine's technical life, regardless of manufacturer. Then it makes granules from the plastic and reprocesses them. "With the igus chainge program, we started recycling the plastic from old products," says Frank Blase, CEO of igus GmbH.

The new plastic life cycle: with the catalytic hydrothermal reactor, plastic waste can be converted into oil, which can be used to make polymer products again. (Source: igus BV)

Back to oil, with water, high temperatures and pressure

However, mixed waste will always exist worldwide. In the case of non-engineered plastics, in quantities 100 to 1,000 times greater. "Chemical recycling offers new solutions in this regard," explains Blase. "In the middle of last year, I read an article about the catalytic hydrothermal reactor in the German newspaper FAZ. The next day I contacted the German inventor Professor Thomas Maschmeyer in Sydney." Seven months later, after intensive research, igus is now investing four million British pounds (=€4.7 million) in Mura Technology Limited and with it the construction of the first Cat-HTR plant. The patented chemical catalytic hydrothermal reactor (Cat-HTR for short) technology was developed in 2007 and tested for 10 years in Australia in a test plant. With Cat-HTR technology, plastic waste previously impossible to recycle can be converted back into oil within 20 minutes; and this means greater resource efficiency than extracting fossil fuels from the ground. Only water, high temperatures and pressure are used to decompose into molecules and reconnect them. One plant alone can process 20,000 metric tons of plastic per year and reduce CO2 emissions by 28,180 metric tons. This is equivalent to the annual consumption of 5,983 cars or the annual energy needs of 4,914 households[4].

Plastic recycling Cat-HTR plant

The first commercial Cat-HTR plant is currently being planned in Teesside, Great Britain, with construction scheduled to begin this year. Waste management companies supply the plastic waste to meet their recycling targets. Oil is then obtained, which can be sold as a replacement for fossil oil. A total of four catalytic hydrothermal reactors are now being built in Teesside and we will be able to process more than 80,000 metric tons of plastic waste per year. As a next step, Mura plans to issue licenses and build new plants worldwide. "We are committed to achieving balance in the plastics business, using technical solutions," says Frank Blase.

To learn more about the Cat-HTR technology, watch the video: https://www.youtube.com/watch?v=dGx4m0KiFac

[1] https://web.unep.org/environmentassembly/estimated-8-million-tons-plastic-waste-enter-world%E2%80%99s-oceans-each-year-0

[2],3 The New Plastic Economy: Catalyzing Effect. January 2017. Ellen McArthur Foundation

Heeft u vragen over dit artikel, project of product?

Neem dan rechtstreeks contact op met Igus.

Contact opnemen

Contact opnemen