Latest developments in durable and reliable clamping

The metals industry is in the midst of change. After all, it must respond to several challenges: the shortage of skilled labor, the demand for greater sustainability, all without losing competitiveness. Where previously the emphasis was on precision and time saving, now flexible approaches are required to change quickly and efficiently between small series. SCHUNK has its answers ready to provide sustainable, efficient and reliable clamping. We would like to introduce you to some interesting developments from the technology leader.

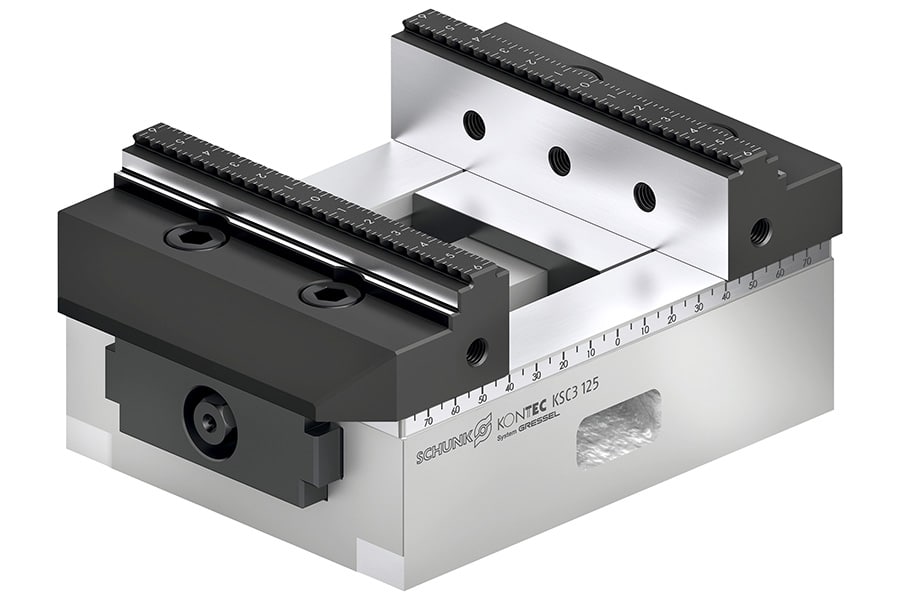

When it comes to reliable workpiece clamping, the KSC clamp from KONTEC has proven to be a highly efficient all-rounder. Now SCHUNK presents a successor with the KSC3, which is not inferior in terms of reliability and precision. The new product also offers optimum corrosion protection thanks to the nickel-plated base housing. This means that the clamp can now be used even in demanding environments such as high humidity. The extremely flat design and improved interference contour ensure optimum accessibility, especially in five-axis machining. This optimizes machine room utilization.

Another plus for process reliability is the encapsulated spindle. The enclosed design with improved chip removal through lateral grooves protects against debris and reduces maintenance costs. Since the bearing is backlash-free, the vise has an excellent concentricity accuracy of +/- 0.01 mm, allowing very precise machining of the first and second sides with only one clamping device.

Three claws for perfection

The success story of the TANDEM3 modular system continues - the new triple force clamp offers even greater design freedom for automated machine loading in four drive variants. Even force distribution ensures safe and repeatable clamping. Like its counterpart with two claws, it also features an advanced lubrication system that ensures high efficiency and constant clamping force. The optimized outer contour ensures controlled chip removal and allows easy access to the workpiece in every operation. Additional cover caps prevent the accumulation of chips.

The clamping device is available in pneumatic (KRP3), hydraulic (KRH3), spring-loaded (KRF3) versions and will soon be available in an electric version (KRE3). Integrated monitoring functions make the centric clamping devices ideally suited for use in automated machine loading.

Award-winning excellence and sustainability

SCHUNK concentrates its product developments on methods that are resource and energy efficient. The ROTA THW3 jaw chuck - awarded the iF design award - masters the balancing act between short setup times and extremely long maintenance intervals. The developers of the chuck have consistently saved weight; this reduces energy requirements and ensures faster acceleration and deceleration of the machine. The durable seal concept ensures up to ten times less lubricant consumption than comparable chucks.

The smart iTENDO² toolholder provides real-time data "closest to the workpiece" and detects tool wear at an early stage. The smart toolholder not only ensures process-secure machining, but also extends tool life and reduces scrap. SCHUNK now offers the toolholder, which received the German Innovation Award, in a new variant iTENDO² Easy Connect with a simple data interface that can be used for machine and process monitoring.

Individual standard terminals

Finally, the new clamp configurator easyJAW is also worth mentioning. Those who cannot find what they are looking for in the world's largest chuck clamp program, with 1,200 types of claws, can now effortlessly design their own soft upper clamps, gripping clamps or monobloc clamps. The geometry, material, weight, interface and many other parameters can be individually customized. Users can thus have customized special clamping clamps within one to three weeks.

With the new planning tools, the application expert offers practical building blocks that take the customization process to a new level. After configuration, users can immediately download the planned solution in any CAD format, request a quotation or order it directly - always with transparent prices and current delivery times. No more time-consuming in-house solutions and weeks of design time - thanks to the new SCHUNK configurators for grippers, gripper fingers and chucks. ■