Voortman Steel Machinery

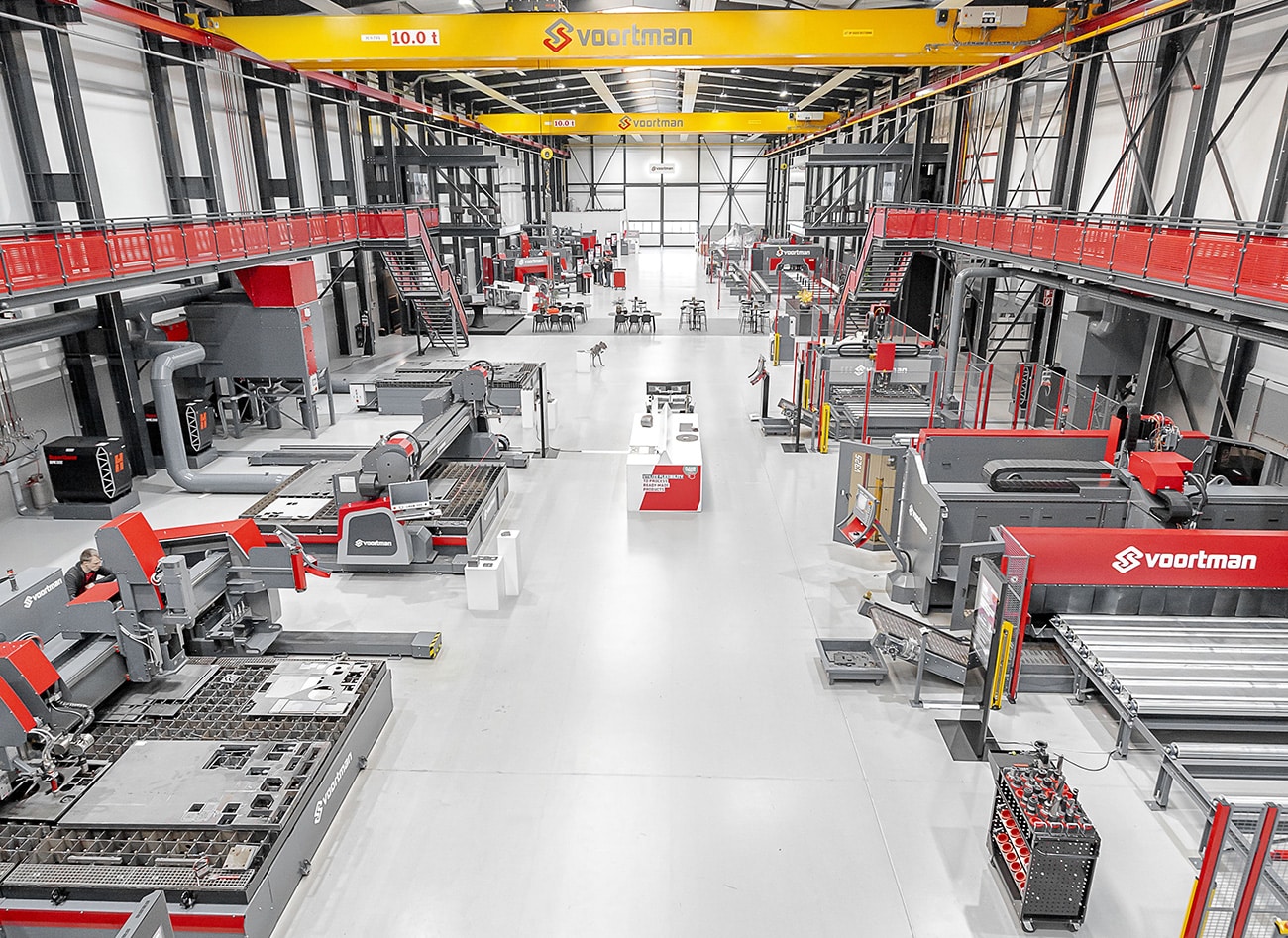

Voortman Steel Machinery makes high-end steel processing machines with integrated business software that automate and optimize your production process. More than 50 years of experience means Voortman can provide solutions for any type of project. Voortman continuously develops new machines and software solutions to meet the increasing demands of the industry. With international branches for sales and service, we work closely with you from start to finish, coming up with customized solutions to your challenges so that you achieve your goals in steel processing.

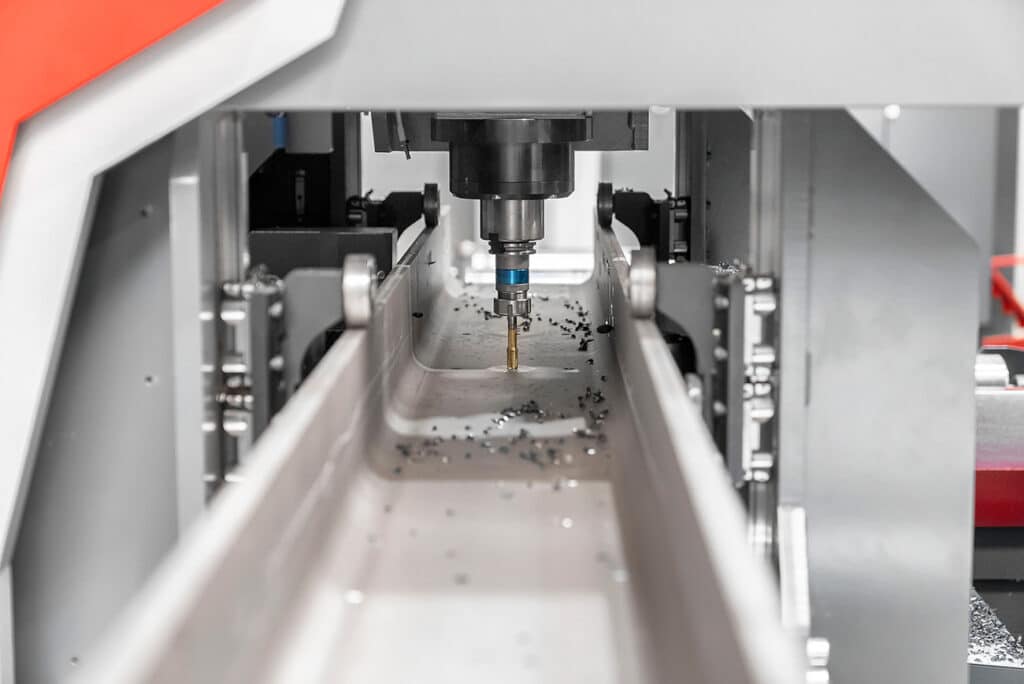

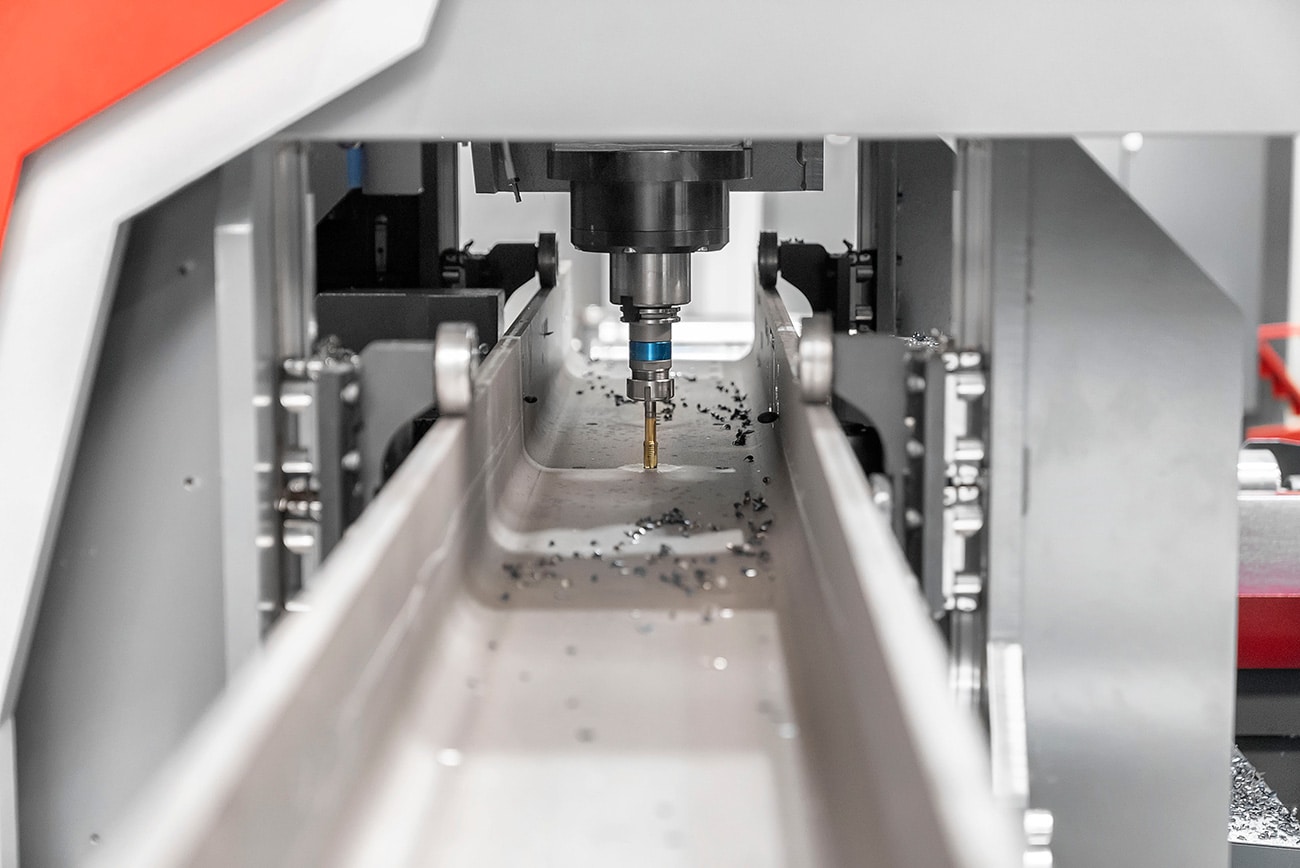

The Voortman V310 can fully automatic carbide drilling, 3D bevel cutting and also full contour milling. VACAM Scheduling and Buffering allow you to run all processes unmanned. The V310 maximizes productivity and uptime, with a dashboard providing valuable information on machining progress.

We are experts in steel drilling and therefore believe our V310 is uniquely positioned in today's sheet metal processing market. Our developers go to great lengths to create a variety of innovative and thoughtful solutions. Every complete product that comes off the V310 relates to our three main objectives:

- High quality with minimal post-processing;

- Strong degree of automation and process intelligence;

- Significant reduction in production costs and manual errors.

Our advanced VACAM Software automates plate production and provides real-time feedback, making unmanned operation very accessible. The Voortman V310 allows jobs to be clustered, multiple plates to be buffered and unmanned mode to bypass manual intervention for extended periods.

The Voortman V630 profile drill offers high productivity with its three independent chucks. Its years of proven performance speak for themselves. It is one of the most economical choices to support drilling, milling and marking operations.

With its 3 independent chucks, the Voortman V630 is the perfect solution to increase productivity in your workshop. It is capable of machining both flanges and the body simultaneously, reducing labor hours and operating costs. Each chuck has an automatic tool changer with six tool positions for various tasks such as drilling, milling, tapping, countersinking, layout marking and center point marking.

Ravings, bolt holes, slots, notches, weld preparations and layout markings - the Voortman V807 can machine it all at once, with the ability to reach all four sides of the material with exceptional speed and accuracy. The V807 combines all of these features to provide a major economic advantage over drilling, milling, sawing, punching, cutting and layout marking machines. By combining these processes into a "do-it-all machine," ROI is achieved faster and less floor space is required in your workshop.

Bedrijfsvideo

Bedrijfsfoto's

Gerelateerde artikelen

Voortman focuses on manless steel processing and total solutions

February 2, 2024 Blechexpo

Blechexpo

Sharing knowledge through webinars

November 8, 2023 Sheet Metal Processing

Sheet Metal Processing

Voortman Steel Machinery progressive in automated and unmanned sheet metal working

November 7, 2023 Sheet Metal Processing

Sheet Metal Processing

Discover the key elements of perfect bevel cutting

September 14, 2023 Welding

Welding

Voortman Steel Machinery introduces the Voortman Fabricator: The leading welding system for structural steel

June 12, 2023 Automation

Automation

Voortman Steel Machinery specialized in digital solutions

June 12, 2023 News

News

Voortman Steel Machinery acquired manufacturer of tube processing machines, Müller Opladen GmbH

June 1, 2023 Automation

Automation

Value chain transformation with Voortman's automation and digitization

May 15, 2023 Plasma Cutting

Plasma Cutting

Unique features support plasma cutting by Voortman

March 22, 2023