Intelligent and flexible clamping technology

The right clamping technology makes all the difference in accuracy and set-up time. SCHUNK offers visitors to Machineering a concise overview of components for clamping workpieces and tools. The focus is on stationary clamping technology, such as the VERO-S pallet quick-change system and MAGNOS magnet technology, as well as tool holders with the TENDO hydraulic expansion technology and TRIBOS polygonal technology. The SCHUNK team welcomes you at Machineering in hall 5 booth B23.

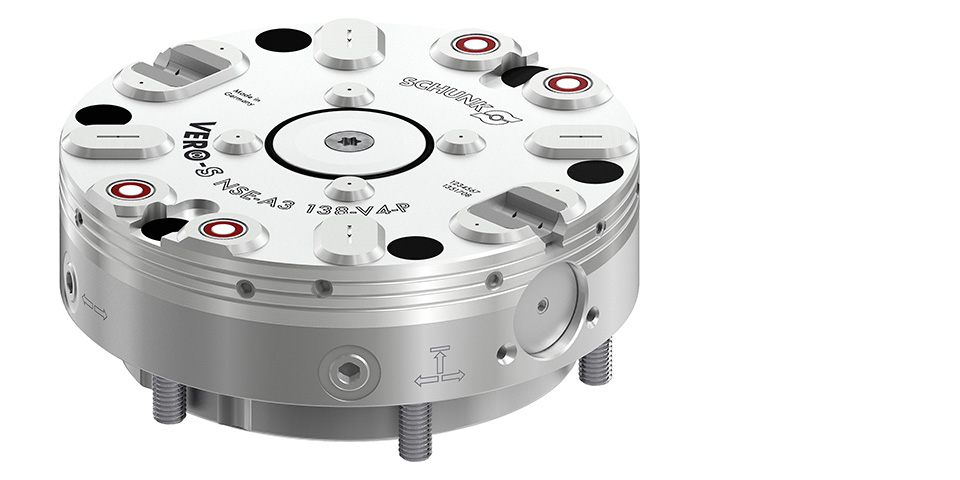

The SCHUNK VERO-S NSE3 138-V4 single clamp module increases flexibility in single pallet applications: while pallet alignment on traditional single clamp modules with anti-rotation protection is fixed as standard, pallets on the VERO-S NSE3 138-V4 can be rotated in 90° increments. This allows the position of the pallet assembly to be varied by 90°, 180° or 270°. Anti-rotation protection is provided by means of two interchangeable flexible elements, which position the pallet. Twee cylindrical pins without positioning function increase radial rigidity and guarantee repeatable positioning of the pallet. The individual clamping modules are available as standard clamping modules or tracing modules. They are suitable for mounting clamping pallets with dimensions of 159 mm x 159 mm. Optionally, the module can be equipped with a spring-activated cone seal, which automatically locks the module interface as soon as the pallet is lifted with the clamping pin. Without changing the height, it locks the last gateway of the otherwise fully closed module.

Pull-down force of 28 kN guarantees 150% higher rigidity

While pallet alignment on traditional single clamp modules with anti-rotation protection is fixed by default, pallets on the VERO-S NSE3 138-V4 can be rotated in 90° increments.

Thanks to the activated turbo function, the dimensionally stable single clamping modules have an enormous downward pull force of 28,000 N. Attachment and positioning take place via a short cone with a repeat accuracy of < 0.005 mm. This guarantees maximum accuracy even in the most demanding applications. The tapered attachment also allows the clamping bolts to be connected eccentrically to the modules, making this process very easy. Actual clamping is performed without an external energy supply via spring force; it is form-fitting and self-locking. The workpieces remain securely clamped even in the event of an unexpected pressure drop in the air system. A pneumatic pressure of 6 bar is sufficient to open the clamping modules. Depending on the thread diameter of the used clamping bolts, the holding forces are at 35,000 N (M10), 50,000 N (M12) or 75,000 N (M16). All components, such as base housings, clamping pins and clamping slide are made of hardened stainless steel, making them absolutely corrosion resistant and durable.

The most comprehensive range to tool holders

Each specific application has different requirements. Especially when it comes to precision, no compromises should be made. The innovation leader sets new standards with its range of tool holders.

iTENDO: the first intelligent tool holder

For safe machining of workpieces in unmanned, automated production facilitiesprocesses, the parts closest to the part must have the necessary intelligence. SCHUNK's answer: the new SCHUNK iTENDO - the first intelligent tool holder on the market.

TENDO E compact: 300% longer service life

The TENDO E compact toolholder has a high clamping force and, depending on the clamping diameter, can safely transmit torques of up to 900 Nm.

SCHUNK TENDO E compact convinces in milling, drilling, reaming and tapping with up to 300% longer tool life. The universal hydraulic toolholder meets the increasing demands in volume machining at a price that makes it easy to switch from Weldon and heat shrink holders to the much more accurate TENDO quality.