Specialist cleans, renovates and preserves climate systems

Companies are increasingly betting on good indoor air quality. After all, this reduces sick leave and increases productivity in the workplace. AQ International helps them do just that. This service company specializes in measuring and optimizing air quality. It cleans ventilation ducts, but also focuses on reconditioning, renovating and preserving air handling units and maintaining large outdoor air conditioning units. Another department deals with the optimization of drinking and process water systems.

Studies have shown that good air quality benefits human health and machine performance. Moreover, since the summer of 2019, companies have had to draw up a risk analysis of indoor air quality in workplaces. AQ International, the Belgian sister company of the Dutch AQ Group founded in 2015, can help them do this and immediately offer solutions to improve quality. This optimization also ensures energy savings, another topic of great importance in our current society.

Bacteria and fungi

"We do not supply and install new installations, but we are a service company to industry, installation and maintenance companies, specializing in the optimization of climate control installations. For example, we inspect and clean ventilation ducts. After all, contaminated air ducts are a breeding ground for bacteria and mold," says Stijn Van Eemeren, director of AQ International. "We are also responsible for reconditioning, renovating and preserving air handling units. We clean the installations, remove rust and at the same time apply a coating that prevents corrosion. Heat exchangers and other components are also subjected to a thorough inspection."

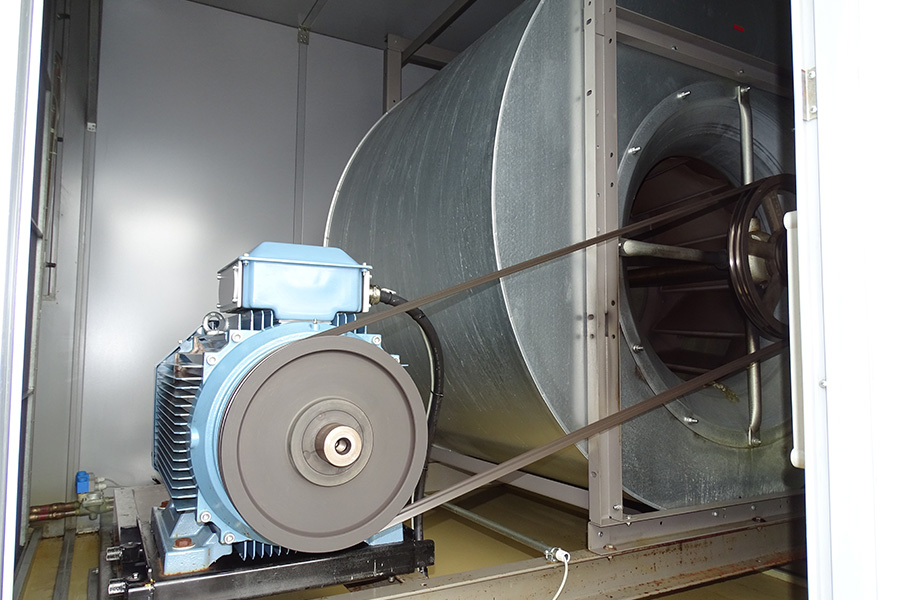

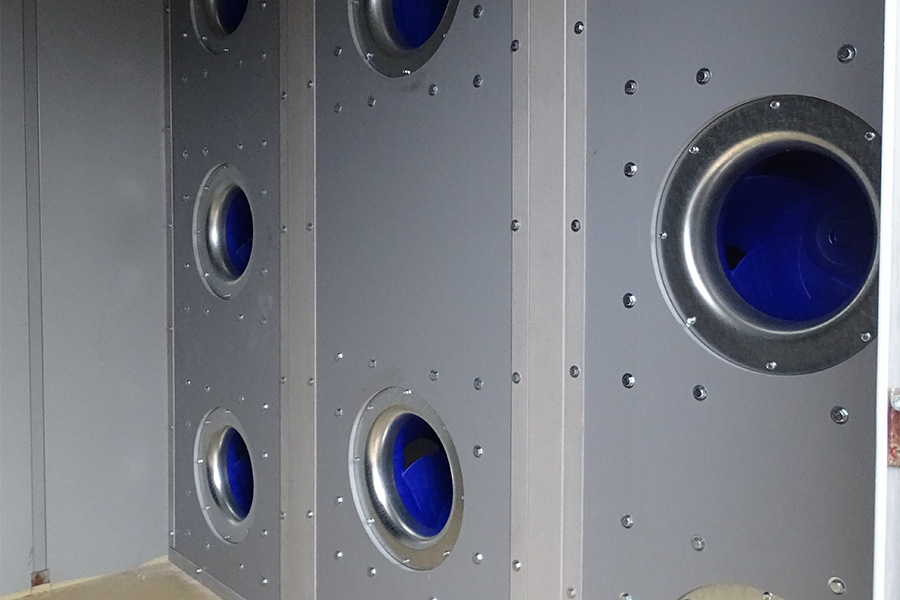

"Furthermore, we pay attention to the energy efficiency and continuity of the systems. We integrate energy-efficient motors or replace one large fan with several small and energy-efficient types, which also require less maintenance. In this way, the installation uses less energy and continues to function even if one of the fans fails. Such a renovation is more environmentally and budget-friendly than a complete renewal. It is also faster and the payback period is less than three years."

Circular filters

AQ International also contributes to a circular economy. After all, the AQ Circle® filters are based on a plastic frame made from recycled material. Moreover, only the filter medium needs to be replaced and the frame can continue to be used. The low resistance of these filters also results in lower energy consumption, and production in Europe avoids long distances, reducing the CO2 footprint.

"In addition to cleaning ventilation ducts and optimizing air handling units, we also specialize in cleaning and coating condensers, dry coolers and chillers, in other words large air conditioning units, for example at data centers," says Van Eemeren. "These devices are constantly in the open air, which makes them highly susceptible to contamination from dust and pollen, among other things. Thanks to proper cleaning - and possibly a coating as protection against corrosion - we ensure that they always maintain an optimal efficiency."

Water treatment and legionella management

Optimization of air quality is one aspect, but AQ International also has a department dedicated to the optimization of drinking and process water systems.

"In terms of legionella management, they are already much further advanced in the Netherlands, but there is also a legionella decree in Flanders in the meantime, and companies are also increasingly thinking about it. For example, we support them in drawing up their legionella management plan, supply and install certified filters and, where necessary, tackle infections," Stijn Van Eemeren concludes. "Furthermore, companies can also come to us for the management and renovation of cooling towers, and for the installation and maintenance of water treatment, UV and humidification systems."