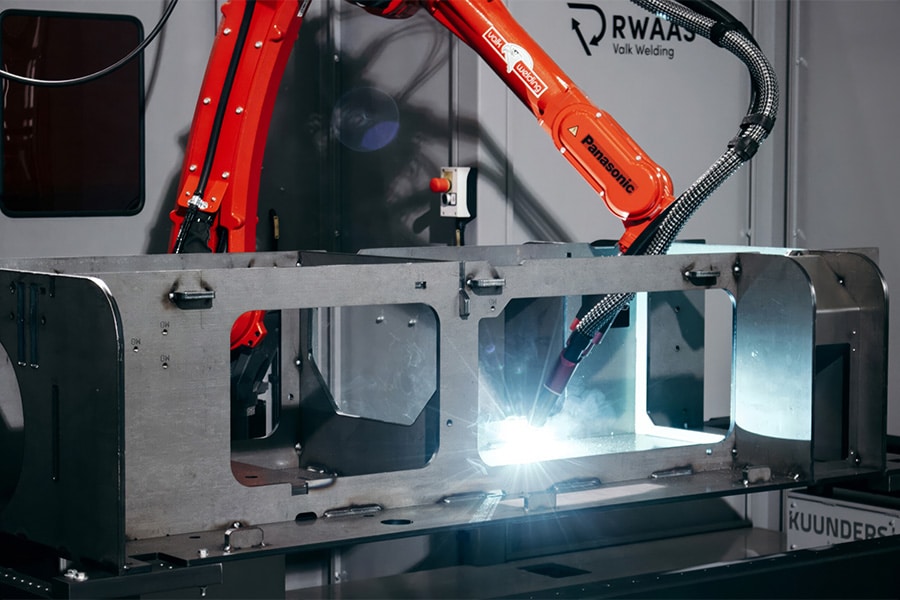

Welding robots with 'Fingerspitzengefühl'

Welding robots have long been used to automate welding operations. In the early days, developments focused mainly on improving speed and accuracy. In recent years, the focus shifted to simplifying the robots' programming. Thanks to this smart software, in which AI plays an increasingly important role, programming is now "piece of cake.

Not only the automotive industry deploys welding robots, but in other industries these specific production robots are also finding their way to take repetitive and complex welding tasks out of people's hands. Robots provide the added benefit of not getting sick, not having a Monday morning temper and working continuously fast and high quality with a high degree of reliability. Roughly speaking, a welding robot allows two to three times as many meters to be welded in a given time frame compared to a human, leading to higher production.

Developments in software and AI

Given the shortage of well-trained technical personnel, the welding robot is becoming increasingly important as an efficient and safe automation solution. Manufacturers are therefore investing in constantly improving these robots. Current developments here are mainly in the area of software and simplifying or even automating programming. Not without reason: companies considering investing in a welding robot often look up to the programming work.

Automatic weld path creation

Attention to this part of work preparation has now led to various ways of simplifying programming. For example, there are possibilities to automatically create the weld path using a step file. Depending on the welding position, only the welding parameters then need to be added. AI will be able to play a role in the future to assign welding parameters to the automatically generated weld path. Other manufacturers work with so-called teach-in procedures in which the various weld points are entered manually after which the software creates the corresponding program.

Deploying AI

Also, AI can be used to simplify programming. For example, the basis is a photo of the product that is converted to a digital 3D image using Lidar. On the screen, the desired welds can be clicked and linked to the correct welding parameters. AI then determines the required program that controls the robot. AI can also be used for quality control. Modern vision systems are capable of checking the quality of a weld seam with high accuracy. Detected deviations and exceeding a predefined limit triggers an alarm. With the increasing capabilities of AI, systems might even be able to adjust the robot based on their findings by adjusting welding or geometric parameters.

Part of the production process

In many cases, welding robots do not stand alone, but are part of an overall production process. Depending on a company's level of automation, the preceding and subsequent processes are increasingly being automated as well. This concerns the supply of the material to be welded and the removal of (semi-)manufactured parts. Often, automating the logistical operations surrounding the entire production process is a somewhat longer process that is completed in stages. For example, after automating the handling of semi-finished products, the user can also proceed to automatically assemble parts into finished products, package them and ship them. With such a far-reaching degree of automation, one of the important things is that the robot can communicate with the overall control system to a certain extent.

Cobots

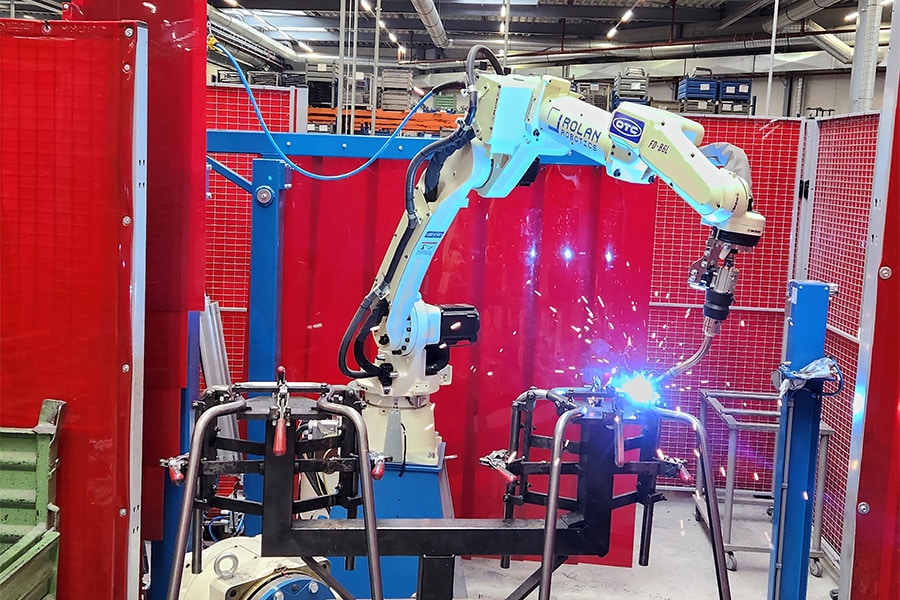

Special attention is being paid to the development of so-called welding robots. Cobot is a contraction of the words "collaborative" and robot. These variants are distinguished from an industrial welding robot by the fact that they are allowed to collaborate with humans. So they do not have to weld behind a fence but safety is ensured by working at slower speeds, for example, and integrating sensors that "sense" when the robot collides with people and objects, after which it is immediately brought to a stop. The hardware of a welding robot does not differ much from that of an industrial welding robot. The distinction is mainly in the software, which therefore makes a cobot slightly more expensive in many cases. With this, the cobot offers several distinctive features such as the ability to learn the desired welding motion. For this, the operator controls the movements of the cobot once, checks the program that is created based on this and can then let the cobot do its thing. This way of working especially offers opportunities to learn and weld simple products quickly. Single pieces will in many cases be more efficiently welded by hand.

Complex welds

Finally, a cobot is also often mobile and thus easier to bring to the workpiece to be welded rather than the other way around. Among other things, this offers opportunities for welding larger workpieces in outdoor locations, such as offshore. There are also opportunities to use cobots to create complex welds by, for example, moving synchronously by following a moving manipulator. These types of applications also make it possible to perform complex welds accurately without the expertise of a professional welder on site.

More user-friendly software

For the future, the manufacturers expect, among other things, an increase in orders from the defense industry, more and more support from AI, an increase in laser welding robots and possibly even more user-friendly software to make it as easy as possible for the end user.