Kumatech first to implement Robot Welding As A Service solution

Kumatech, a fast-growing scale-up specializing in AGVs and internal logistics solutions, has become the first company to deploy Valk Welding's RWAAS solution. RWAAS, which stands for Robot Welding As A Service, offers a complete service in which a welding robot system can be deployed without a large initial investment. This system was delivered in the morning and was operational at Kumatech the same afternoon.

Reasons for choosing Kumatech

Kumatech chose the RWAAS solution because of the company's rapid growth and the need for a flexible and cost-effective solution. By choosing RWAAS, Kumatech was able to scale up production within one day without any major financial investments. This allows the company to maximize its resources and quickly increase production capacity. The predictable monthly costs of RWAAS allow the company to better manage financial planning and avoid unexpected expenses.

The RWAAS system from Valk Welding

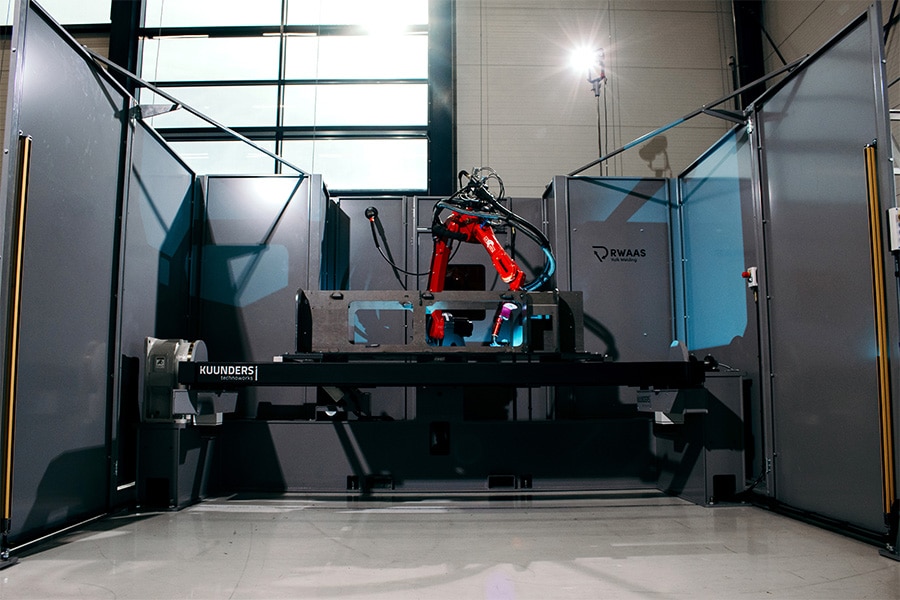

Valk Welding's RWAAS system includes an advanced welding robot designed specifically for the arc welding process. The welding robot has a long reach and is robustly built to ensure the highest quality and productivity. The system is equipped with an integrated power source that enables seamless movements and a consistent welding process regardless of the material, such as steel, aluminum or stainless steel. The welding robot is mounted on a FRAME-C, a compact and space-efficient frame that is easy to set up and equipped with all necessary safety measures.

In addition, the system is equipped with the VWPR Fume Extraction torch. The torch extraction effectively removes fumes and other vapors, contributing to a safe and clean working environment. This eliminates the need for large extraction systems. Torch extraction is the most effective way to extract welding fumes because it takes place directly at the welding area. This means that the fumes have no time to mix with the clean air, requiring only a small amount of air for extraction.

Innovative software support

When implementing RWAAS, Kumatech also gained access to the ARP powered by ArcNC software. This software enables automatic programming of welding robots, drastically reducing programming time from several hours to as little as 15 minutes. The software analyzes 3D CAD/STEP files, identifies welds and suggests weld positions and sequences. Once approved, the software automatically generates the complete weld program, including all search movements.

Employee benefits

The introduction of the welding robot does not mean job losses. On the contrary, it allows employees to focus on more challenging tasks. Two Kumatech employees, Joep and Teun, took operator and ArcNC training and can now fully program and operate the robot. This allows Kumatech to respond quickly to market demands and is less dependent on outside suppliers and manual welders.

Future Prospect

Kumatech strives to provide the best AGVs and is very cost-conscious about production resources. In the long term, the company wants to integrate more intelligence into the welding robot to ensure quality and performance. Machine learning and artificial intelligence are crucial in this regard. The ARP powered by ArcNC software plays a key role in this strategy. Kumatech looks forward to future developments where small design changes and different product variants can be automatically recognized and programmed without human intervention. This will further improve production flexibility and responsiveness.

Heeft u vragen over dit artikel, project of product?

Neem dan rechtstreeks contact op met Valk Welding B.V..

Contact opnemen

Contact opnemen