Innovation in the Steel Industry: Valk Welding and Vrolijk Steel Concepts

Thanks to good cooperation with various partners, a steel plant of the future now stands.

Less than three years ago, the Vrolijk Group started a new division: Vrolijk Staalconcepten. Thanks to good cooperation with various partners, there is now a steel plant of the future. Karel Vrolijk, CEO of the Vrolijk Group, once started his career himself on the shop floor of the steel plant where Vrolijk Staalconcepten is now located. At the time, this steel plant was part of the South Dutch Steel Construction.

The Vrolijk Group has now grown into a large and innovative construction company. In 2022 everything came together when the old steel plant of Hollandia, on the spot where Karel Vrolijk himself once started, was taken over: Vrolijk Staalconcepten was born. Thanks to its knowledge of construction, Vrolijk has developed a progressive steel concept that optimizes construction processes. By standardizing the entire process - from engineering to fabrication and assembly - construction projects are accelerated without compromising on quality. The entire process is now in-house, allowing optimal control and flexibility to be offered.

The choice of Valk Welding

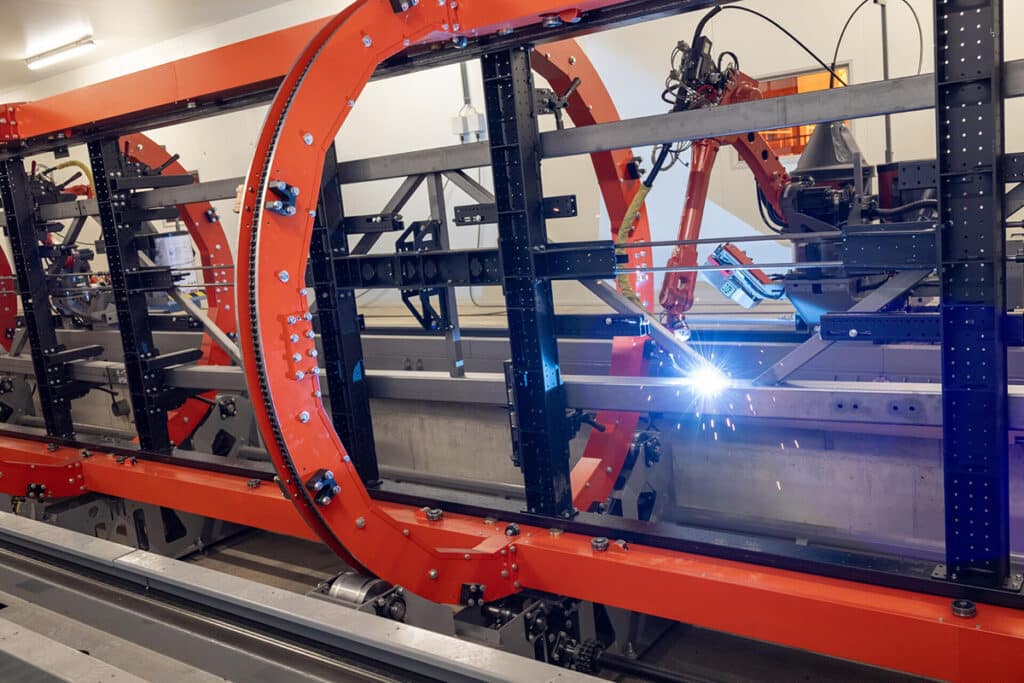

Marcel Boks, director of Vrolijk Staalconcepten, was part of the team responsible for setting up the new plant. "Valk Welding was the most advanced in terms of knowledge and expertise for the product we wanted. The mechanical part was an essential part of our welding robot and in cooperation with Kuunders they were specialized in this. In addition, Valk Welding had already installed a similar concept at a trailer builder, which appealed to us greatly," says Marcel Boks.

"The cooperation with Valk Welding went well. They not only take their responsibility seriously, but are also solution-oriented. Also, the technical support is of a high level. Valk Welding is a pleasant party to work with," says Marcel Boks.

Valk Welding goes beyond just supplying a welding robot system. We strive for "The strong connection" and innovation, so that both we and our customers can be proud of the welding robot system.

Efficient and sustainable steel production

The system is designed so that trusses 24 meters long can be placed, manipulated and welded in a single operation. This innovative concept allows the entire product to be welded on all sides by four (or more if needed later) welding robots. This is therefore a unique concept with many advantages for the very long products of Vrolijk Staal concepts. Once the product is welded, it is exported again. The carousel is designed to hold two molds, which remain at an ergonomic height for the operators when filling the mold safely. This whole project came about thanks to the good cooperation between all partners,in this project 'The strong connection' was central!

Heeft u vragen over dit artikel, project of product?

Neem dan rechtstreeks contact op met Valk Welding B.V..

Contact opnemen

Contact opnemen