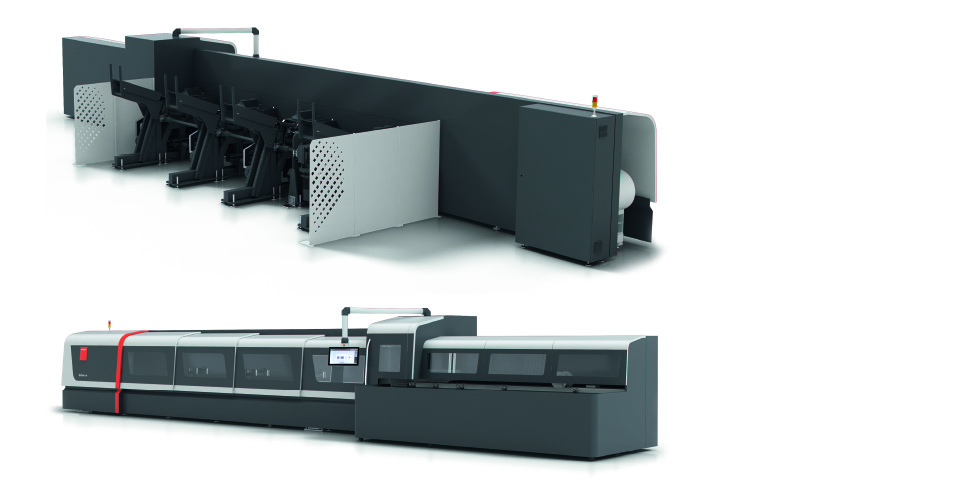

The right tube laser cutting machine for optimized production

Whether round, square, rectangular or asymmetrical shapes, it is difficult to cut pipes optimally without a laser. They have revolutionized the cutting process, especially when it comes to complex geometries. But there is a lot involved in integrating such technology into a production process, especially with larger profiles. Therefore, it is best to get to know them extensively so that you can choose the most cost-effective tube laser cutting machine for your products.

With a tube laser, an operator can accurately cut out holes and contours in a single step, reducing the need for manual handling in subsequent processes.

By applying laser cutting to profiles, it became possible to realize completely new product designs in one fell swoop. Where previously welded joints were often used, by laser cutting pipes and profiles, products can be brought to a stronger and more aesthetically pleasing result. In many cases, this also brings with it a weight saving, without sacrificing strength, and easier assembly and mounting afterwards. It has already inspired many companies to invest in a tube laser cutting machine in their production. But it also certainly offers potential for suppliers looking to expand their market. To arrive at the right choice, several variables must be examined: product design, process simplification, cost reduction, response times are the most important ones.

Once a company has identified what added value a tube laser cutting machine can bring to its production process, the machine must be optimally configured according to the application.

Less manual handling

With a tube laser, an operator can accurately cut out holes and contours in a single step, reducing the need for manual handling in subsequent processes. With the advent of drawing programs and customized software for the machines, a workpiece can also be programmed for laser cutting faster than ever before. This means that even small series can be done profitably. A tube laser not only proceeds to process pieces quickly itself, but requires only minimal set-up, allowing pieces to be delivered just-in-time for the next operation.

Cutting power and capacity

Cutting power is one of the most important factors in choosing a tube laser cutting machine. With typical capacities of 2 to 4 kW, most standard materials such as profiles in mild steel or aluminum and steel in typical thicknesses can be cut efficiently. But those who have high quantities of aluminum or stainless steel to process will be best looking forward to higher power. Capacity is a second consideration. Profiles come in a wide range of sizes. Those who make their own products can easily match the machine to the desired length of those profiles. For suppliers, that will be a little more difficult to determine. What lengths are common? How many profiles do I want to be able to load at once? After all, one will also have to consider the weight capacity of the tube laser cutting machine.

Cutting power is one of the most important factors in choosing a tube laser cutting machine.

Supply and disposal of materials

How to feed the raw material is also a determining factor. A typical laser cutting machine that cuts typical pieces will do so so quickly that manual loading and unloading is difficult to keep up with. This is why tube laser cutting machines are equipped with a bundle loader. This provides the machine's magazine with a bundle of tubes, good for several tons of material. To reduce loading times when cutting, a buffer magazine can already receive a number of tubes. Thus, only a handful of seconds are lost. However, it is still appropriate to keep the manual loading option checked as well. That way, if you are running a large series, for example, you can quickly take out a small order. The unloading zone can be adjusted according to the length of the profiles coming off the machine.

Where previously welded joints were often used, by laser cutting pipes and profiles, products can be brought to a stronger and more aesthetically pleasing result.

Weld seam detection and mitre cutting

Today, profiles are still very often welded. However, the weld seam can interfere with the laser cutting process and thus the final assembly. Tube laser cutting machines with the right hardware can detect the seam along the outside of the tube. But there are also systems that can use cameras and light sources to also look inside to detect any welds. Once that is done, the controller adjusts the orientation of the tube to minimize the impact of the weld on the finished product. Cameras can also come in handy to correctly load and clamp asymmetrical profiles. The stop is then adjusted according to the detected profile for a reliable cut. Finally, it is also important that the cutting head is suitable for mitre cutting. For this, the cutting head must be able to swing 45° in any direction during the cutting process. Then add an additional high-speed axis and productivity can be increased with 30%.

Decision

Once a company has identified what added value a tube laser cutting machine can bring to its production process, the machine must be optimally configured according to the application. For example, a loading zone that is too short can have a negative impact on the efficiency of nesting finished parts. On the other hand, a system that is too long will involve a higher investment cost and take up more floor space than necessary. Therefore, seek the manufacturers' advice and also ask to cut your pieces to evaluate each option and ensure the best possible ROI.