Stone finishing technology in Hembrug hard turning machines

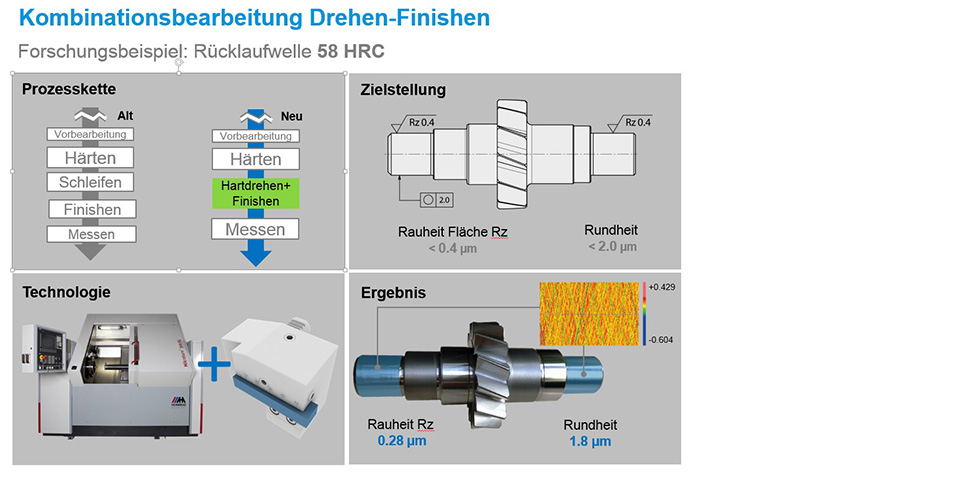

Hembrug Machine Tools has signed an agreement with PTGoldAU UG for the exclusive supply of stone finishing technology called KombiFin. The agreement applies only to hard turning and cylindrical grinding machines. PTGoldAU UG, headquartered in Magdeburg, Germany, has been working on the market introduction of high-precision surface finishing technology on modern CNC machines since 2017 after more than 15 years of research. In return for the exclusive supply of this KombiFin technology, Hembrug is making available a Mikroturn 100 hard turning machine. They will use it for trials and jobber related work.

The finishing process is a long-established process and is used, for example, in the production of highly loaded seal and bearing seats on drive shafts for hydraulic pumps, for example. This is a high-volume process with one type of workpiece and where pre- and post-processing is carried out on separate machines. The KombiFin technology, however, involves small, sensory stone processing units that can be easily integrated into modern CNC machine tools. Post-processing on a separate machine is therefore no longer necessary.

The integration of these systems into the Hembrug Mikroturn® hard turning machines now makes the finishing process available to manufacturers of small to medium series with a variable workpiece spectrum. For example, they can achieve a spiral-free surface structure that is not possible with hard turning alone. The stone finishing unit can be easily mounted in the tool changer. The rotation of the workpiece and the movement of the stone finish unit are thus performed by the hard turning machine. The oscillation of the stone finish tool and the contact force is controlled by the control unit of the attachment.The process can be cooled either with oil or emulsion.

Thus, with the integration of stone finishing technology, pre- and post-processing can now take place on a single machine. This saves process steps, costs and very high surface (< 0.3 µm Rz) and shape accuracy ( < 2 µm) can be achieved. Hembrug has a test machine with this new technology and has already successfully carried out several customer tests.