Spanners 2.0: the return of modern classics

Are tensioners old-fashioned? On the contrary according to Schunk's experts in clamping technology. Especially in times of automated machine loading, there is a relentless demand for mechanical clamping devices. The leading leader in gripping systems and clamping technology has systematically created a program of universal basic clamps that can be used for a wide range of applications.

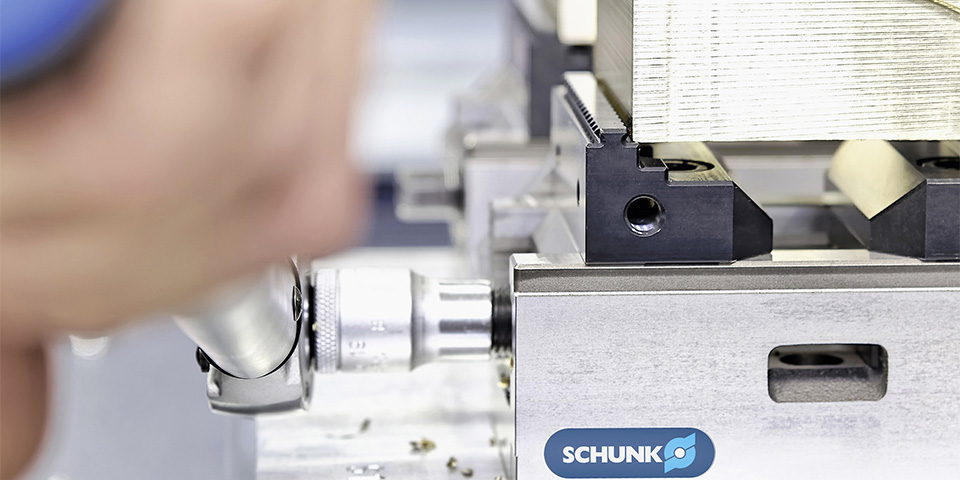

Modern mechanical clamping devices have little in common with classically designed tensioners. The tensioners from the basic range have become extremely precise and user-friendly powerhouses that generate high clamping forces in a compact space. The manually driven tensioners from the basic range of the SCHUNK KONTEC KSC series are highly efficient centipedes for machining both raw materials and finished parts. They are driven by a spindle protected by a fully enclosed system. The tensioners can be operated quickly and easily with a torque wrench. Even with a relatively low torque, they can achieve clamping forces of up to 50 kN (size 160). Since clamping is done under tension, the bending load on the base element and thereby the raising of the tensioners is minimized. This further contributes to the accuracy and rigidity of clamping. The modular structure of the portfolio, a special feature of the SCHUNK tensioners from the basic range, ensures that the tensioners can be used for a wide range of standard applications. The attractively priced clamping systems are available in three basic versions.

Centric clamp tensioners

The KONTEC KSC manual centric clamping system is a multitalent among stationary clamping systems. From classic clamping and low clamping depths for machining along five sides to pre-formed parts, plates or saw cuts, the KONTEC KSC adapts in an instant and ensures high accuracy and high clamping forces despite its extremely flat design. Workpieces can be clamped reliably in less than a second. A preloaded, backlash-free, carriage-mounted center bearing ensures a repeat accuracy of up to +/- 0.01 mm so that both raw and finished parts can be accurately machined in one clamping system. The fully encapsulated drive system and an integrated chip removal system provide particularly high process stability and minimum wear. The attractive price of the KONTEC KSC allows pallets to be stored particularly economically.

Single acting tensioner

The KONTEC KSC-F single-action tensioner with fixed clamp is specially designed for use in automated machine loading. It manages to impress with its fast clamping range adjustment, flat design and low weight - perfect features for use in all machining centers. Thanks to the quick clamping option with 160°, workpieces are clamped accurately at lightning speed with the torque wrench and the tensioner is securely locked. The sizes KSC-F 80, KSC-F 125 and KSC-F 160 are specifically designed for normal pallet sizes of 320 x 320 mm, 400 x 400 mm and 500 x 500 mm.

Simply activate with a torque wrench and the SCHUNK KONTEC KSC gripping clamps work their way into the workpiece, without having to spend too much time applying structure to unmachined parts beforehand.

Double acting tensioner

The KONTEC KSC-D is a lightweight and flat double-acting tensioner developed primarily for continuous use in automated machine tools with workpiece storage. By means of a convenient third-hand function, two workpieces in collet towers can be placed side by side, fastened and clamped securely together. Thanks to trapezoidal threads, high clamping forces can be achieved with minimum effort. An induction-hardened base element, long clamping guide, attached skids, hardened clamping heads and a fully encapsulated actuator ensure high accuracy, maximum wear resistance and minimum cleaning effort. The fully nickel-plated tensioners are protected against corrosion for continuous use in pallet systems or on truss towers.

Smart quick change functions

The three variants are available in sizes 80, 125 and 160 with different base element lengths. In terms of workpieces, users can choose from a wide range of standardized upper clamps and thus benefit from maximum flexibility. Thanks to the clamp quick-change system, both standard clamps and workpiece-specific clamps can be changed in just a few steps. Depending on size, the clamps cover enormously large clamping ranges from 0 to 458 mm (KSC), from 0 to 463 mm (KSC-F) and from 0 to 331 mm (KSC-D, two workpieces) using reversible clamps. To keep setup times to a minimum, the KONTEC KSC tensioners from the basic range can be combined with the SCHUNK VERO-S quick-change pallet system. For this, the clamping pins of the quick-change pallet system are mounted directly into the base element of the tensioner without an adapter plate. Thus the tensioners can be loaded onto the machining table, onto clamping towers or onto clamping pyramids in just a few seconds and with maximum repeat accuracy. Here, too, the flat design of the KSC series pays off. Multiple KSC tensioners can be combined for clamping long parts.

Magnetic workpiece supports and plugs

For EMO 2019, SCHUNK has expanded its range of basic clamps by two useful extras: magnetic work supports in different heights can be placed on the clamps in just a few steps without the use of screws. This allows a defined clamping depth with a high accuracy of +/- 0.01 mm, ensuring maximum parallelism of the contact surface. In addition, the magnetic holding force prevents the supports from shifting or falling while changing the workpiece. Because the bearings can be attached and removed quickly and easily, first and second settings can be repeated on a single tensioner without the need for a clamp change. The magnetic stops are mounted and adjusted just as quickly. In this way, exact positioning of workpieces and high repeat accuracy are possible.