New saws bring precision and peace of mind

Did you know that Belgium is internationally at the top in new developments for fully automatic filling machines for the paint industry? We owe that position to De Vree of Merksem. In order to maintain that position, the company recently invested in modernizing its sawmill, the crucial first step in the production process. Promatt and Behringer gave De Vree the accuracy it was looking for.

Promatt and Behringer gave De Vree the accuracy it was looking for.

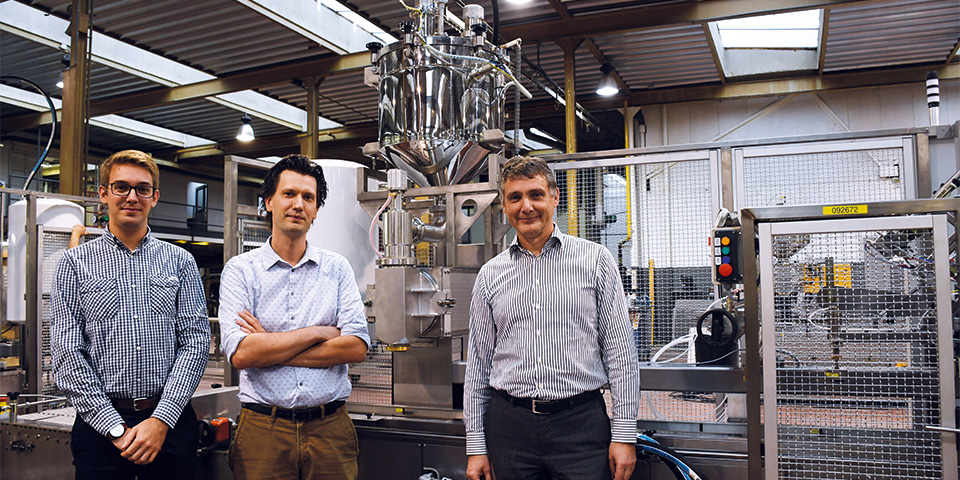

The De Vree story really takes off after World War II. Jos De Vree's expertise in filling machines gets publicity and orders follow one after another. This specialty is the thread that runs through its history. Today, the Antwerp company delivers an average of thirty fully automatic filling machines a year for the paint industry and seventy semi-automatic ones. Managing director Erik Stuer: "Offering the customer 100% satisfaction is our ambition with each machine and our key to success. In other words, service is highly valued. Although we work with standard components, every order is in fact customized and finished according to the customer's wishes. This is why the entire development (construction, electronics, pneumatics, software ...) still so much possible in-house."

De Vree of Merksem is absolute world leader in filling machines for the paint industry.

Quality above all

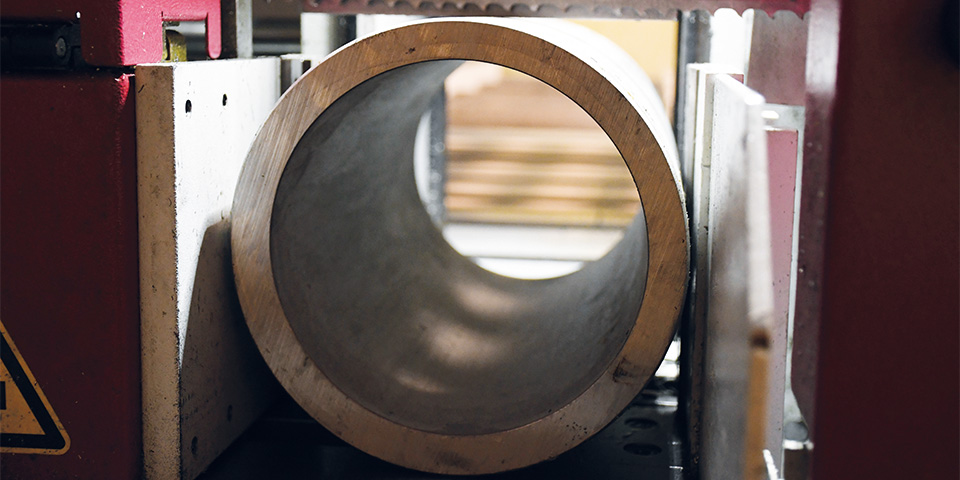

So the machinery at De Vree does not have to process large runs. That means that not speed but quality takes precedence. One of the most important areas on the shop floor is the sawing department. Mechanical engineer Johan Van Hove: "We saw all materials to size, even for pieces that we subcontract. Our sawing department is therefore permanently loaded and is actually the best possible gauge of our company." Ever since the 1980s, De Vree has chosen Behringer to be sure of its quality and reliability. The fact that the first machine from 1985 is still running anno 2018 is the best proof of that for De Vree. "Still, it was time to invest and modernize," Stuer points out. "The two band saws in production had to work constantly. We couldn't afford breakdowns. So we added a new Behringer, which can actually handle the capacity of both. The machine runs much faster and our operators prefer working with it."

Eric Stuer: "Choosing only one supplier in the sawing department offers advantages in terms of efficiency and cost of maintenance."

A lot of confidence

Van Hove is also impressed, in part because of the new capabilities that were added. "We can now cut up to 320 mm, where before we were limited to 250 mm. Moreover, the machine itself knows perfectly what to do. The operators actually only have to enter the right parameters and it goes to work quickly and accurately. We can run it alone at night with complete confidence." A second order also followed from Promatt. The circular saw that had been there since '89 was in need of replacement. Van Hove: "There was wear on it, which caused quality problems when cutting frames with a mitre. This was no longer done accurately enough, which caused problems further down our production chain." That it became Behringer again also had to do with the fact that De Vree liked to stay with one company for the sawmill. "That offers advantages in terms of efficiency and cost of maintenance. But above all, you know what you have on each other. Promatt also prides itself on its service. For example, there have been some minor technical problems, but they were immediately addressed and solved professionally. That gives a lot of confidence and makes us real partners," Stuer concludes.