New opportunities thanks to fully automated tube laser

To respond flexibly to customers' often demanding demands, companies must continue to invest in new machines. Laser Works, the division within thyssenkrupp Materials Belgium that focuses on laser cutting, bending and finishing of metal sheets, profiles and tubes, recently installed a fully automated Adige fiber tube laser type LT8.10. Result: increased capacity and the ability to machine workpieces from other materials and with other shapes.

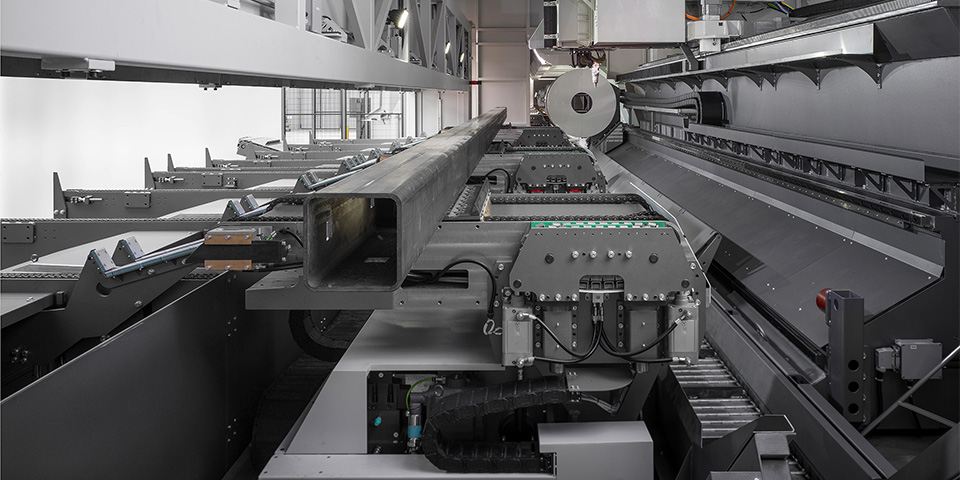

The tube laser is suitable for machining round tubes up to 240 mm in diameter or rectangular profiles up to 200 mm thick. The fiber source also cuts pipes with special shapes, open profiles and hook-in connections.

Laser Works (Merelbeke), a division of thyssenkrupp Materials Belgium since 1999, has specialized in laser cutting of sheets and tubes for more than twenty years. "We perform jobs for our sister companies, but we are also a reputable service provider for other metal processing companies," states Olivier Goubau, laser cutting product manager. "We laser and bend sheets, profiles and tubes in stainless steel, steel and aluminum and are responsible for post-processing. To do this, we have modern machinery, which is continuously adapted to help our customers."

Adige fiber LT8.10 tube laser

Therefore, Laser Works recently installed a fully automated tube laser Adige fiber LT8.10 for workpieces up to 6.5 m in length and weighing up to 40 kg/m. This innovative unit relies on a 3 kW fiber laser source and is suitable for round tubes up to 240 mm in diameter or rectangular profiles up to 200 mm in thickness. This machine imports 3D models from various CAD programs and automatically converts them into the data needed for production. "Thanks to 3D technology, not only round, square or rectangular pieces can be programmed and cut, but also pipes with special shapes, open profiles or hook-in connections. Moreover, this fiber source also has no trouble cutting aluminum and other highly reflective materials," adds Goubau. "This tube laser is equipped with a beam loader in the back for automatic processing of larger series and also has a step loader in the front for individual workpieces, which allows a running production to be briefly interrupted to process one or a few pieces in between. The finished pieces can be unloaded in the front as well as in the rear."