New in our range and on display for the first time in the Benelux during the Promatt Demo Days

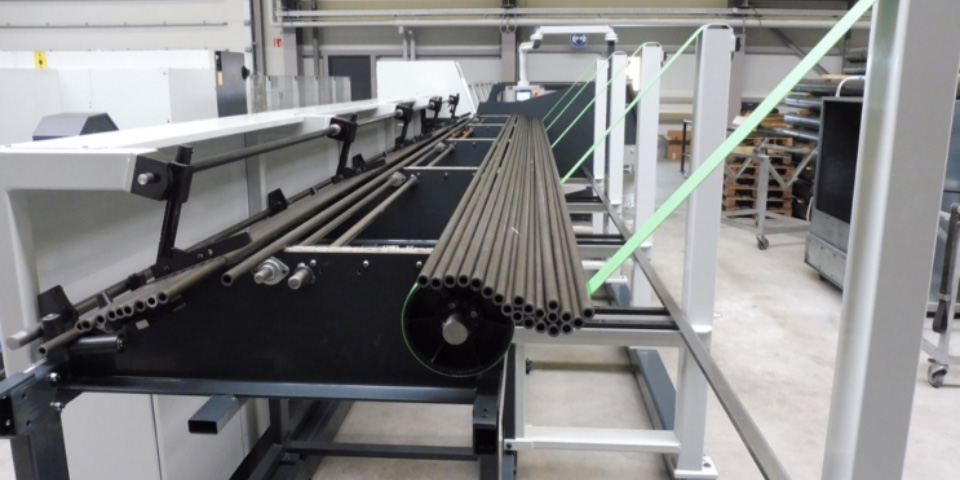

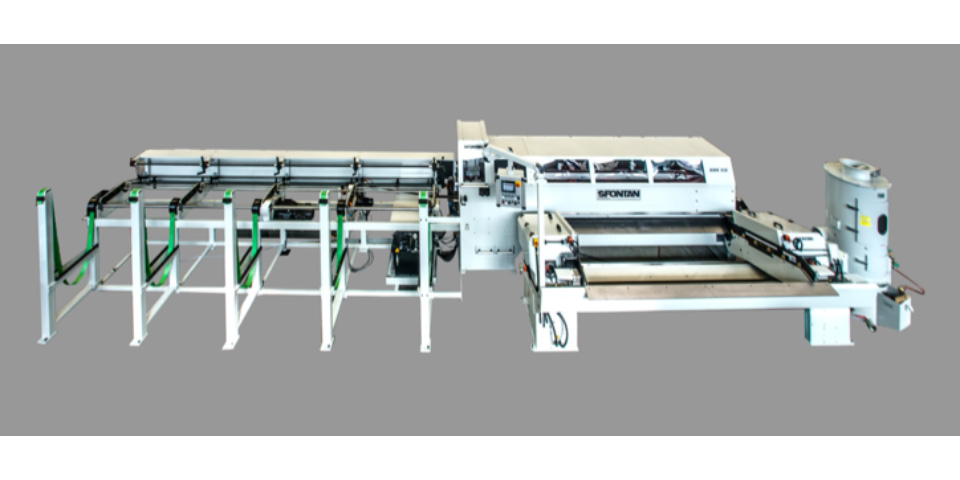

High-speed tube saws with deburring units from the German brand Spontan.

At Spontan Trenn- und Entgrattechnik in Remscheid, the focus is still on customer requirements. The specialist in sawing and deburring technology builds high-quality and highly flexible machines for the efficient sawing of pipes and tubes in small and large series. The sawn parts can then be automatically deburred. Because of this flexibility, Spontan's machines are particularly suitable for companies that process different pipes and tubes with different cut-off lengths interchangeably and still want a high output.

During the DemoDays on October 3 and 4, we will demonstrate the Tube Saw HRS 315 for automatic sawing of tubes and tubes from Ø 8 mm to Ø 108 mm in combination with a bundle magazine and deburring unit, the HBE90.

The main features of this sawing system are:

- High capacity utilization due to short changeover times and universal clamping jaws minimizing downtime.

- Highly dynamic and precise, servo-controlled measuring stop for quick change of cut-off lengths, with a travel speed of as much as 500 mm/sec.

- Servo-controlled saw drive for variable and constant speed for optimum stock removal.

- Stepless saw feed via current control valve or proportional control valve, where the control automatically selects the predetermined saw feed.

- NC controlled saw stroke limitation (upper and lower point) for minimum side times.

- The DUO Microlube Advantage minimum cooling & lubrication system developed by Spontan for longer tool life and optimum (dry) cutting performance.

- 2-way sorting of cut parts (to the front and back).

- Automatic separation of head cuts and residual pieces.

- Automatic positioning of deburring brushes to the length and size of the cut parts.

- Drain to the rear of parts that do not require deburring.

- Clean blowing system for the inside of tubes.

- Dust extraction at the deburring brushes.

- Quick and easy setup and operation of the entire system via the centrally mounted control panel.

- Reliable support from an experienced and committed service team.