New compact control cabinets save up to 30% space and time

The key to successful digital transformation is the smart integration of processes that create value. At Hannover Messe, Rittal unpacked its solutions to put this into practice. This included new enhanced system products, digital processes and an Industrie 4.0 factory that sets customers the right example. The highlight was undoubtedly the presentation of the new generation of compact and small enclosures: the AX and KX series. Like their bigger brother VX25, which got its baptism of fire at last year's Hannover Messe, they are bursting with new features and also save up to 30% of space and up to 30% of assembly time.

Industrial intelligence is all about seamless connections between people, machines and data. At

its 1,550 m² booth at Hannover Messe, Rittal highlighted the added value that end-to-end digital integration brings. Uwe Scharf, Managing Director Business Units and Marketing: "Our digitized product portfolio combined with direct interaction with customers from all branches of industry are the best basis for achieving the highest possible process efficiency. We have understood the imperatives of a digitized industry and developed a new generation of compact and small cabinets in response. Together with the introduction of the Blue e+ series and the large cabinet system VX25, all of our core products have now received an Industry 4.0 makeover. Customers will reap the benefits of the new features that help streamline and emphasize value-add processes, while also improving flexibility and reliability."

The VX25 Ri4Power is the system technology for assembling safe low-voltage enclosures and power distribution boards according to IEC 61439.

The launch of the small and compact enclosures marks the digital transformation of a standardized product that Rittal has been making for 50 years. With 35 million units produced, AE is the world's most popular compact enclosure. The new AX and KX will now continue that success in a digitized world. Rittal unpacks with thirty new features that respond to trends toward more decentralization and more sensors and actuators to capture data.

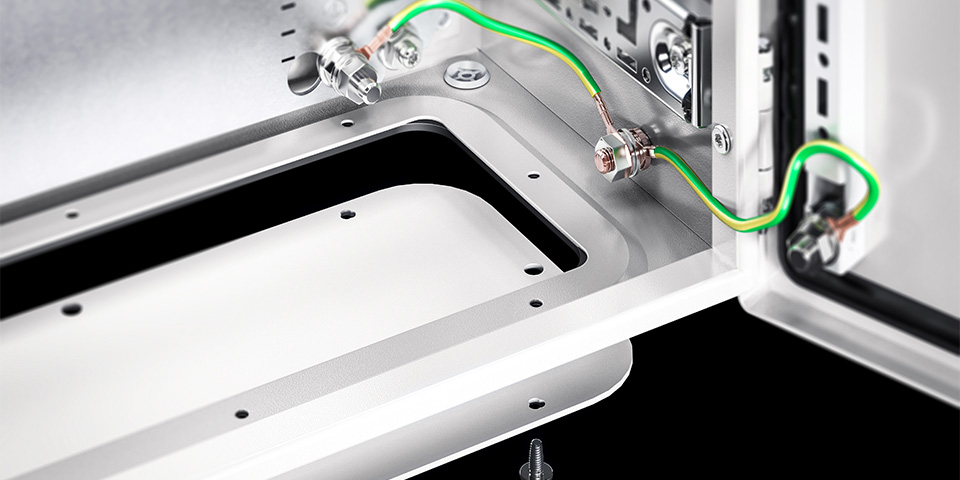

In addition, users will save assembly time and 30% space with the new 30% compact cabinets. Time savings begin with the delivery of the materials. The panels are delivered unassembled, so there is no disassembly work to be done before getting started. In addition, installing doors, for example, has become a lot easier: there are no more tools involved. An additional advantage is the extra space available in the AX and KX series compared to their predecessors. Cables are always being added to connect sensors in the work area, for example. The modular design, improved cutouts and larger plates provide a third more space for cables. And the integration of installation rails can also be done easily, accurately and quickly. The KX series starts from 150 x 150 x 80 mm and is especially suitable when only a few components need to go into the junction box or bus enclosure. The AX series is available with a depth between 210 mm and 400 mm and in a maximum dimension of 1,000 x 1,400 mm.

Modular design, improved cutouts and larger plates provide a third more space for cables

Rapid integration of system components

Rittal has not been idle in the field of power distribution either. The VX25 Ri4Power will be extensively presented to the public. This is the system technology for the composition of safe low-voltage enclosures and power distribution systems according to IEC 61439. The busbar system can be perfectly integrated into the VX25 enclosure system and standardized installation kits (for each enclosure width) ensure simplified mounting, as no holes need to be drilled. In addition, they guarantee fast integration of system components. Compact NH fuse switch disconnectors are also easy to install thanks to proven adapter technology. The touch-safe design and the use of an integrated, operation-independent spring mechanism also result in maximum safety. VX25 Ri4Power ISV modules also fit into the VX25 enclosure. This implies the necessary advantages for the construction of distribution boxes in industrial building technology, in accordance with IEC 61439. As with the 185 mm system, easy mounting of the ISV modules in the cabinet is guaranteed thanks to the use of special installation kits. The combination VX25 control cabinet system and modules offers a high protection class, while in aggressive environments the modules can also be integrated into the stainless steel version of the VX25 standard cabinet.

Tangible benefits through digital products and services

Together with the introduction of the Blue e+ series and the large enclosure system VX25, all Rittal core products have now received an Industrie 4.0 makeover.

Above all, Rittal showed at Hannover Messe that its expertise extends beyond individual products with intelligence on board. Digitalization, standardization and automation require a more integrated approach across the entire value chain. That starts with delivering all possible digital product data and configurators to engineers and work preparation processes creating a digital twin of the cabinet, enabling digitally connected production. But industrial intelligence goes a step further. By unleashing algorithms on data to monitor and analyze management systems, faults or component failures can be reliably detected. Active solutions such as cooling systems, chillers and machines can be connected via sensors and IoT and IIoT interfaces to Rittal platforms such as EPLAN eView and RiZone or to standard platforms such as Siemens MindSphere. This creates even more value creation for customers.