Higher productivity in mold and die production.

Dormer Pramet's range of cutters for mold and form making has been further expanded with new cutters with diameters of 12-20 mm (SCN05C) and of 20-35 mm (SWN04C).

SCN05C milling cutters for productive copying are suitable for machining steel, hardened steel and cast iron and are available from 12 to 20 mm diameter. The dense toothing provides a productivity improvement of at least 20% over milling cutters with standard pitch.

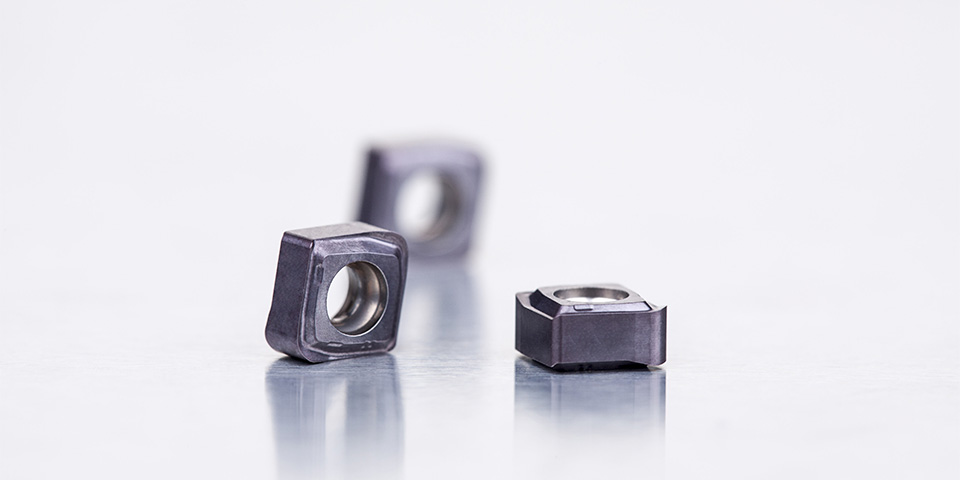

Dormer Pramet's double-sided CNHX05 change plates feature four cutting edges.

This is supported by a range of double-sided CNHX05 change plates with four cutting edges. With high-quality surface quality, the unique patented Wiper edges contribute to shorter machining times during angle and surface milling

SCN05C cutters are suitable for contour milling, profile milling, insert milling and surface milling. Thanks to vibration reduction, the tool is optimized for smooth machining of corners and recesses.

SCN05C cutters increase productivity during copy milling in steel, hardened steel and cast iron.

Dormer Pramet additionally introduces the SWN04C productive copy cutters. The SWN04C cutter is available from 20 to 35 cm in diameter and features an uneven tooth distribution that contributes to optimum surface finish. The cutter is designed for the change plate with as many as six cutting edges.

A characteristic feature of this cutter is its smooth running, even at long projection lengths, and can therefore be used for contour milling, profile milling, slot milling and surface milling at cutting depths of up to 2 mm.

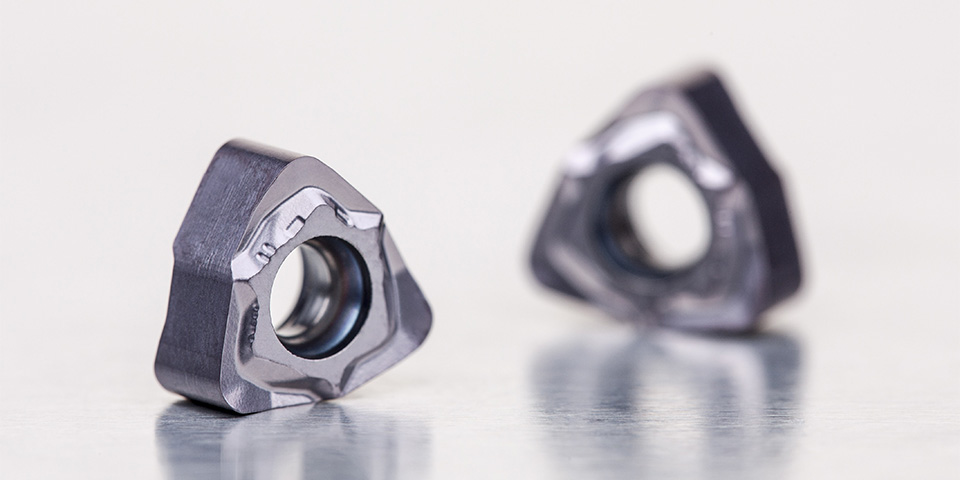

The double-sided WNHX04 changing plate features six cutting edges.

Like the cutters in the SCN05C series, the SWN04C tools are suitable for semi-finishing and finishing operations in steel, hardened steel and cast iron for stamping and die production.

The WNHX change plate with WM geometry and the new carbide type M4310 were recently used for machining in finished steel with a depth of cut of 0.5 mm. At a speed of 196 m per minute and a feed of 3,600 mm per minute, the tool reduced machining time by 45% compared to a - competitive product.

For more information on the new products, contact your local Dormer Pramet sales office or download the new product brochure from www.dormerpramet.nl.

The SWN04C series is suitable for semi-finishing and finishing operations in steel, hardened steel and cast iron.

On our YouTube channel www.youtube.com/dormerpramet you can see the new range of cutters in action.