HARVI TM I TE by Kennametal - Your New Best Friend

Four-tooth, solid carbide cutter provides superior performance for steel, stainless steel, high-temperature alloys and cast iron.

Kennametal announced the latest addition to its best-selling HARVI line of powerful solid shank cutters, the HARVI I TE solid carbide cutter with four chip grooves. With a radical new design, the HARVI I TE delivers outstanding performance in a wide range of materials, including steels, stainless steels, high-temperature alloys and cast iron - with life to match. And thanks to significantly reduced cutting forces, this action-changing tool can be used on any machining center or milling center in the shop floor

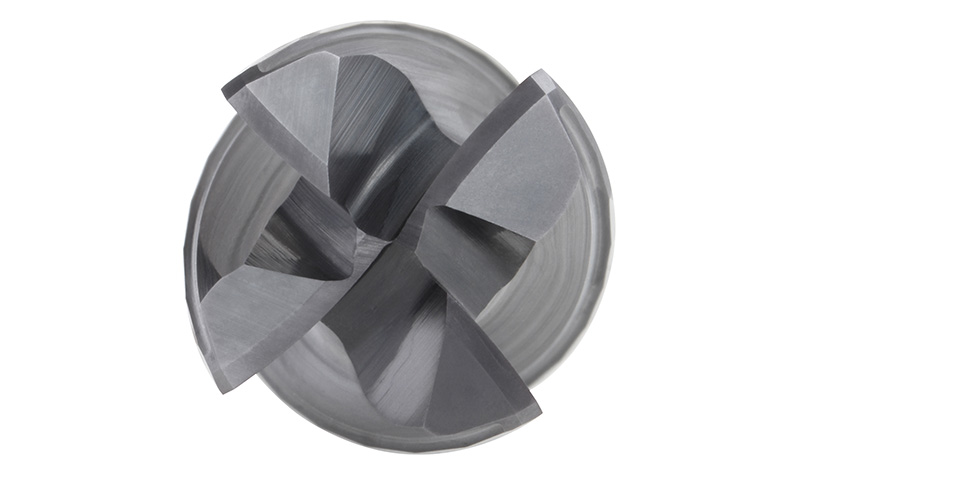

Much of the machine magic happens here, with HARVI I TE's innovative turned head surface. Improved angular stability, allowing smooth cutting even at the highest angles of inclination.

"The HARVI I TE consistently outperformed competing four-cutter cutters in both wet and dry machining tests on a variety of materials and applications, with unprecedented longevity in many cases," said Bernd Fiedler, Manager, Solid End Milling. "It performs exceptionally well on tough roughing and finishing applications - from deep cavities and full-width slots to shoulder and dynamic milling."

Kennametal engineers designed the HARVI I TE to address four key problems that plague more than 90% of all milling applications: chip removal, tool flexing, angular stability and fracture due to radial cutting forces. The result is a tool durable and versatile enough to tackle the lion's share of milling applications.

Consider chip removal. The HARVI I TE has an innovative chip groove design that helps chip form and break chips into manageable shapes, while a series of chip guides in the chip groove work those chips upward, away from the workpiece. Both serve to promote coolant flow, reduce chip recutting and improve tool life. A twisted end face and unique shape further promote chip removal, but are also responsible for the HARVI I TE's amazing vertical and infill milling capabilities.

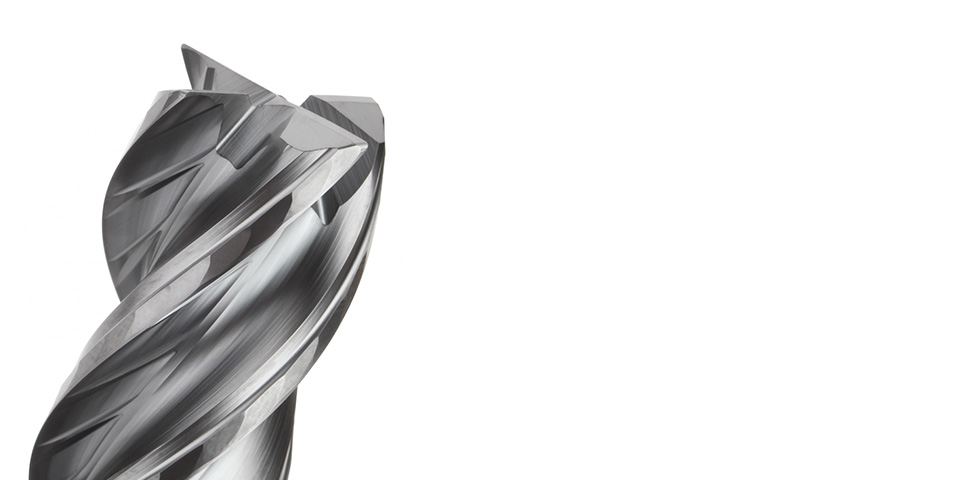

Anti-vibration anti-friction technology- AVF. A precisely faceted eccentric relief for excellent cutting conditions in multiple material types

Tool deflection is reduced thanks to the tool's parabolic core, as well as an eccentric, faceted relief along the entire length of the chip groove that significantly reduces cutting friction. This relief also increases edge strength, making the tool versatile.

Along with a variable pitch angle and asymmetric chip slot distribution, it dampens vibration before it can negatively affect machining operations.

"The HARVI I TE improves process stability, surface quality and chip removal," Fiedler said. "Most importantly, it maintains these advantages even at increased feed rates, cutting speeds and depths of cut - for maximum chipped volume, tool life and productivity."