Faster, more efficient and cheaper sheet metal processing

Outsourcing often brings logistical hassles and lost time. For DelwiGroenink Machinefabriek, these were the two main reasons to invest in its own sheet metal working machines in 2015. Important links in the production line are now the Phoenix FL-4020 laser cutting machine and LVD's ToolCell bending bench, all linked via the same manufacturer's smart software. "We now work faster, more efficiently and cheaper. It was a big investment but we are future proof again," sums up owner Johan Delfsma.

Johan Delfsma: "Thanks to the integration of sheet metal working machine, the CADMAN software and our ERP package, we have made huge strides in both production and administration."

DelwiGroenink Machinefabriek develops and manufactures complete lifting and transport systems for Hyva International. The company also works on a project basis for clients in logistics, chemicals, offshore and equipment construction. Since the takeover in 1996 of metal company Groenink, growth has been unstoppable. A rapid development that also had its drawbacks. Delfsma: "We outsourced a lot, such as the blasting and coating of parts. But the requirements became increasingly stringent. OEMs expect innovations and more competitive rates. Competition worldwide is tough, so you have to stand out. The question is how."

Own production to differentiate

DelwiGroenink found the answer in expanding production. Part of the factory was equipped with new disciplines including laser cutting and a large blasting and coating line. As a result, in one fell swoop Delfsma no longer has to outsource anything, costs drop dramatically and capacity doubles. Since completion in mid-2018, sales have been skyrocketing. There is now a healthy company on over 2.3 acres of its own land with over 130 people on the payroll. The new warehouse is the provisional crowning glory of a quarter century of passionate entrepreneurship. LVD plays a leading role in it. "Back in 2014 we invested in an Easy-Form bending bench with 400 tons of compressive force. We knew immediately that we had to knock on their door for the second bending bench as well."

With the CADMAN® suite, everything hangs together and DelwiGroenink gains transparency into the various layers of sheet metal production.

Only ones that could guarantee accuracy

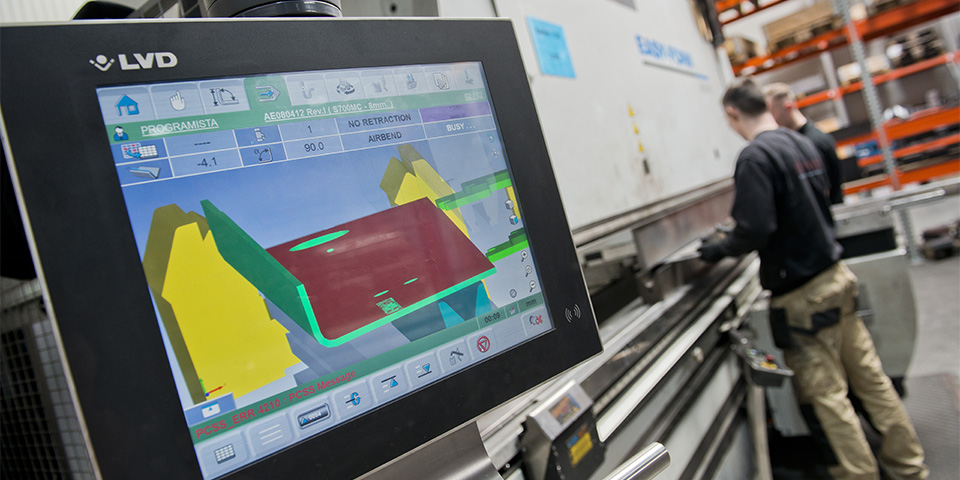

This time it became a ToolCell with automatic tool changer. "LVD was the only one willing to guarantee a bending angle accuracy of ± 0,3° with their Easy-Form laser system," Delfsma points out. In addition came LVD's Phoenix FL-4020 laser cutting machine and a fully automated storage system from Remmert. To the outsider, it seems simple. Every day about 20 tons of steel is fed fully automatically to the laser cutter and the bending bench, controlled from the CAD department that makes the designs. The Phoenix cuts everything to size; the Toolcell takes care of the precise bending work. Next, the products are robotically welded to then go to the blasting and coating line and finally assembled. Says Delfsma, "We now have an ultramodern production line that eliminates transport movements and shortens lead times - to the great satisfaction of the customer. With the CADMAN® suite hangs everything together and we get transparency into the different layers of sheet metal production."

Every day at DelwiGroenink, about 20 tons of steel are fed to the laser cutting machine and bending bench fully automatically.

Link

Cooperation with LVD was optimal. "Together with LVD we spent an intensive period setting up, assembling, training people and linking all the systems together. The ERP system is linked to the CADMAN® software from LVD and sends purchase orders to production. There the bending solutions are calculated largely automatically and nestings for laser cutting are created. The operators on the shop floor see the information relevant to them on their machine controls and execute. The machine feeds production information back to the system so that management always has real-time data. Thanks to this integration, we have made huge strides in both production and administration," Delfsma summarizes.

Attractive

The results are slowly becoming visible on the books. "We are growing very fast. Fortunately, we manage to find good people because we offer good working conditions and present ourselves as a sustainable and social company. DelwiGroenink may be a manufacturing company, but it is high-tech, with attractive and innovative products. Automated and robotized. Sexy? I think so," concludes Delfsma.