Conventional or controlled, always fast, safe and efficient milling

For metalworkers, versatility is crucial. No programming time needs to be lost on simple pieces, but at the same time CNC technology is crucial to efficiently deliver large series or complex pieces. The precision milling machine PICOMAX 56 TOP is therefore available with a patented operating concept, namely the FEHLMANN TOP functions (touch or program). This allows the machine to be operated both in three-axis NC and manually. This means that the machine can be used efficiently even after a very short setup time without programming knowledge by any craftsman. In Belgium, distribution is done by Buhlmann.

The standard mounted direct measuring systems allow modern machining methods with optimum accuracy.

The PICOMAX 56 TOP is a powerful, easy-to-use machine tool for machining parts, prototypes and tools or training. Thanks to a rigorously strong focus on single pieces and small series, it has achieved an excellent price/performance ratio. The basic version of this machine "Made in Switzerland" offers all the features worthy of a modern, powerful milling machine, such as the Heidenhain TNC 620 touchscreen control, a cooled Fehlmann high-torque motor spindle for universal milling up to 12,000 rpm, as well as tapping with ZS interpolation, 3D milling, boring ...

CNC or conventional?

The new generation of the TNC 620 combines the typical advantages of the proven HEIDENHAIN controls with modern control technology such as select, shift on a touch screen. This combination of intuitive control technology, context-sensitive operation and the proven HEIDENHAIN operating concept makes work easier and saves time in production. But not all pieces benefit from CNC technology. Therefore, the machine also has the capabilities for conventional milling. It is equipped with a manual lever for height control in Z and electromechanical handwheels for X and Y travel. The milling, drilling and tapping of individual parts can therefore be carried out quickly, safely and efficiently without programming.

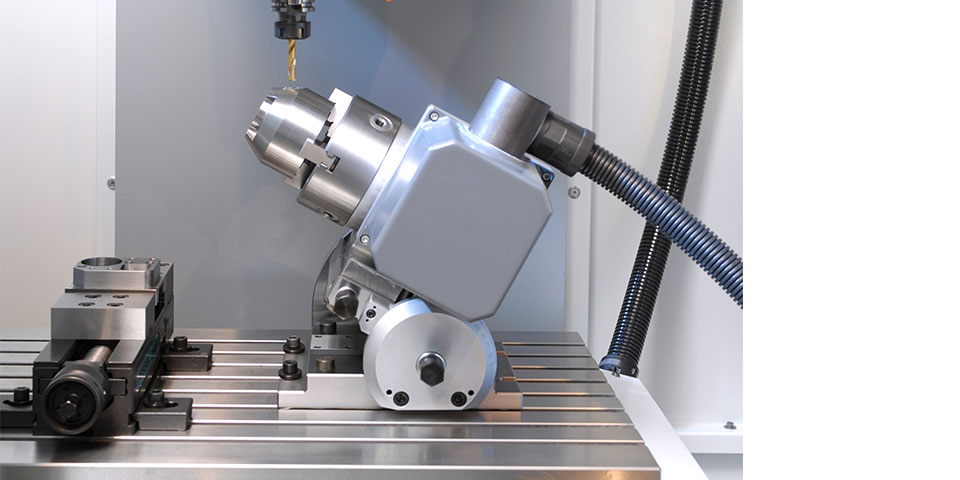

Up to four axes can perform work simultaneously on the PICOMAX 56 TOP.

Always optimal accuracy

The standard mounted direct measuring systems allow modern machining methods with optimum accuracy. The optional installation of a tool changer with twenty or thirty places, a fourth NC axis and other useful options are available. The many practical operating aids and perfect ergonomics make the PICOMAX 56 TOP a complete and modern workstation.

Also available in the L version - with even greater clamping range on an extended table

This L version of the FEHLMANN PICOMAX 56 L TOP offers an extended X-travel of 800 mm and a clamping range of 1,400 x 480 mm. Very long workpieces can be machined in one step without changing clamping. There are even more possibilities for four-axis machining with among other things, a swiveling distribution head). Long workpieces can also be machined efficiently due to the increased distance between the distribution head and the counterpoint.

Optional tool changer can be selected.

Fehlmann AG, the specialist for Swiss precision machine tools

Since 1930, the Swiss family-owned company Fehlmann AG has been developing and manufacturing precision machine tools for milling and drilling. Concept, construction, manufacture, commissioning, maintenance and training: FEHLMANN brings the entire production at Seon in Switzerland under one roof with more than 200 employees. In Belgium, Buhlmann is responsible for the distribution and service of these machines. With over seventy years of experience, the Buhlmann team can perfectly support you in design, project management, assembly, maintenance and quick interventions.