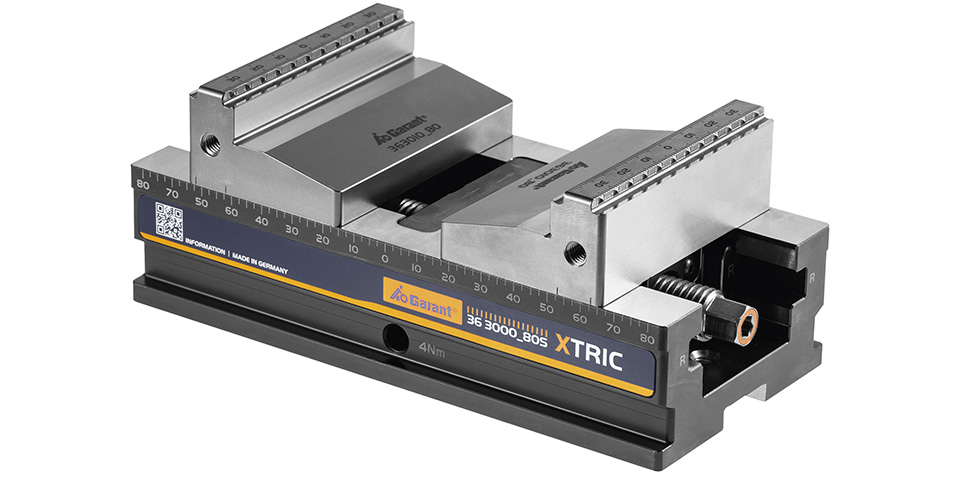

Click & Clamp" with the GARANT Xtric centric machine clamp

Jaws quick-change system reduces setup times of machined and unmachined parts; preforming for machined materials with grip jaws is not required

GARANT Xtric is called the new centric machine clamp from the Hoffmann Group. The machine clamp is equipped with an innovative jaw quick-change system, which enables uncomplicated, fast and tool-free changeover and changeover accuracy in the micrometer range via a click mechanism.

Attachment jaws that can be rotated 180 degrees provide a large clamping range and high variability when clamping workpieces. For clamping across multiple GARANT Xtric units, the center can be precisely adjusted to achieve maximum precision. Because the maximum clamping force of up to 25 kN actually reaches the workpiece, there is virtually no lifting of jaws or workpiece. The GARANT Xtric is therefore well suited for clamping both machined and unmachined parts. Pre-forming of the part is not necessary, which saves up to 50 percent of set-up time.

Click & Clamp: The GARANT Xtric's jaw quick-change system with click mechanism allows quick jaw changes without tools.

With the new centric machine clamp GARANT Xtric, the attachment jaws can be changed or rotated 180 degrees in just a few simple steps - and completely without tools.To do this, the attachment jaws are inserted into a dovetail and pushed down via two spring plates until they engage. The spindle nut therefore does not have to be screwed in and out. With this unique click system according to the motto "Click and Clamp," the GARANT Xtric can make a significant contribution to reducing set-up costs. Thanks to its rotatable attachment jaws, the Xtric offers a particularly large clamping range of 0 to 144 millimeters for model 80S and 0 to 194 millimeters for model 80M. Another model with a jaw width of 125 millimeters is already on the market during EMO. All models are also available with pendulum jaws. These contribute to a significant increase in process reliability.

With GARANT Xtric, the clamping force of 25 kN is applied directly to the workpiece. This makes the centric machine clamp also suitable for clamping raw parts. In addition, when a grip jaw with GARANT tooth form is used, preforming is not necessary.For customers, who use the system "Lang", there are suitable attachment jaws with the tooth form "System Lang". The attachment jaws are available both uncoated and coated.

The new centric machine clamp GARANT Xtric offers a particularly high clamping range thanks to 180-degree rotatable attachment jaws.

For clamping larger workpieces via multiple centric machine clamps, you can micrometer-accurately adjust the clamping center on GARANT Xtric and shift it as required per side by up to 0.5 millimeters - i.e. a total of one millimeter. All you have to do is loosen the side screw, readjust the center using a wrench and tighten the screw again.

Longitudinal grooves for precise alignment on the machine table, bores for the Lang positioning system and adapter plates for clamping on the GARANT Zero Clamp zero point clamping system round out the program. Adaptation to other zero clamping systems is also possible.

The new centric machine clamp GARANT Xtric will be available from July 8, 2019 through the Hoffmann-Group eShop and can be ordered from August 1, 2019 through the new 2019/2020 catalog.