Welding symbols explained simply

WHAT ARE WELDING SYMBOLS FOR?

Welding symbols serve to technical aspects of the welding works to communicate from the designers to the shop floor, so that welders and supervisors/inspectors know what is expected. This way, one can be sure that the final product meets the design criteria.

Of course, it is important that draftsmen use the correct symbols and shop floor personnel interpret them correctly. So proper training is crucial. Otherwise, costly mistakes will happen.

SYMBOLS ACCORDING TO THE NEN EN 22553 STANDARD

In our country, we usually use the European standard for welding symbols (NEN EN 22553). Thanks to this international standard makes it easier to share welding work between departments and companies, even those located in other countries.

More info on the NEN EN 22553 standard can be found at nen.co.uk.

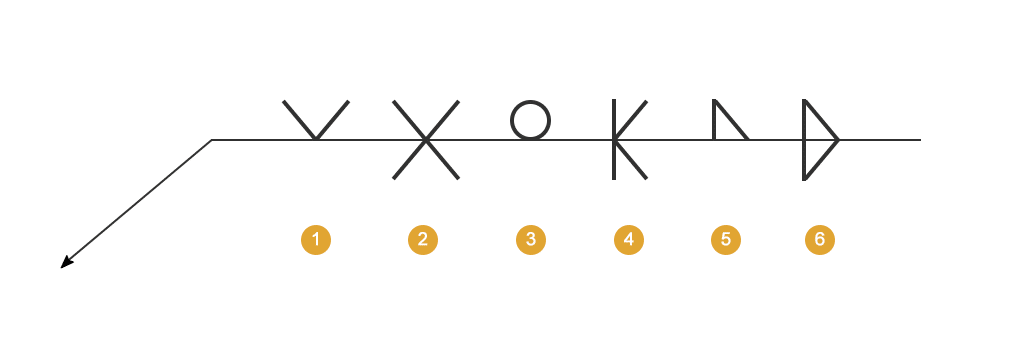

ARROW

Usually the designer adds welding symbols to the arrow line at more complex joints. Below are some examples:

1. V-seam

2. X-seam

3. Spot weld

4. K-seam

5. Angle class

6. Double corner weld

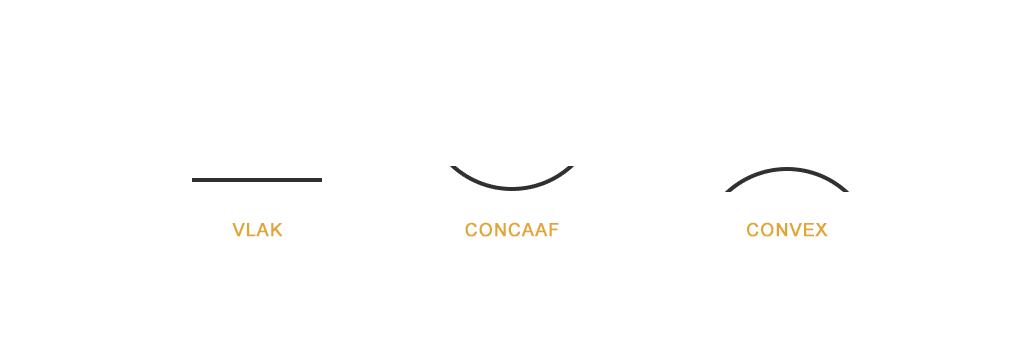

SYMBOLS FOR THE SHAPE OF THE WELDING SURFACE

The above welding symbols can be supplemented by additional indications to clarify the shape of the surface. This can be flat, convex (convex) or concave (concave).

SYMBOLS FOR WELD EXECUTION

Furthermore, we have symbols for the weld execution:

- Seam transition, smooth

- Permanent melt pool support (M)

- Temporary melt pool support (MR)

SIZES

To ensure that the correct size weld is applied, it is common to add additional information to the left or right of the symbol. For example, consider the desired nominal throat height or leg length.

YOU'LL DEFINITELY FIND THIS INTERESTING TOO!

In a previous article, we explained the types of welding edges you can create from a flat plate. The different methods provide a stronger construction and a cost savings. Read the full article here

Customized guidance?

Come to our showroom, see the full range and test for yourself!

Or call us at +32 9 377 29 49