Advanced technology without heavy investment thanks to entry-level or Pre-Owned machines

For smaller workshops, medium-sized companies, start-up products or manufacturing companies where bending or cutting are not core competencies, high-end machine tools are just a step too far. Therefore, they usually resort to second-hand machines or cheaper models, often resulting in poor quality. Bystronic wants to offer this new customer segment high-quality solutions at low entry-level costs. This is why the specialist is introducing the Xpress bending machine and why customers can also turn to it for young used and fully reconditioned systems under the label "Pre-Owned by Bystronic.

Bystronic is a leading global manufacturer of high-quality systems for metal sheet metal processing. The intelligent coupling of bending benches and laser cutting machines with innovative automation, software and service solutions is the key to comprehensive digitization of the sheet metal industry. "With the ByCut Smart, ByStar Fiber and BySmart Fiber, we offer a suitable solution for every laser cutting application. Those looking for a suitable bending bench can also choose from a variety of systems with us," says area manager Erik Goven. "With the Xpert series, the range includes a suitable solution for companies that need to bend workpieces up to 10 m long and/or require a press force of up to 1,000 tons. For applications with a required press force of up to 300 tons for profiles up to 4 m long, as for example at our customer BMWill Building Solutions in Herstal, we propose our Xact Smart. We introduced the Xact Smart just like the Xpress so that everyone can enjoy our advanced bending technology without having to make an overly large investment."

New quality standard in the lower price segment

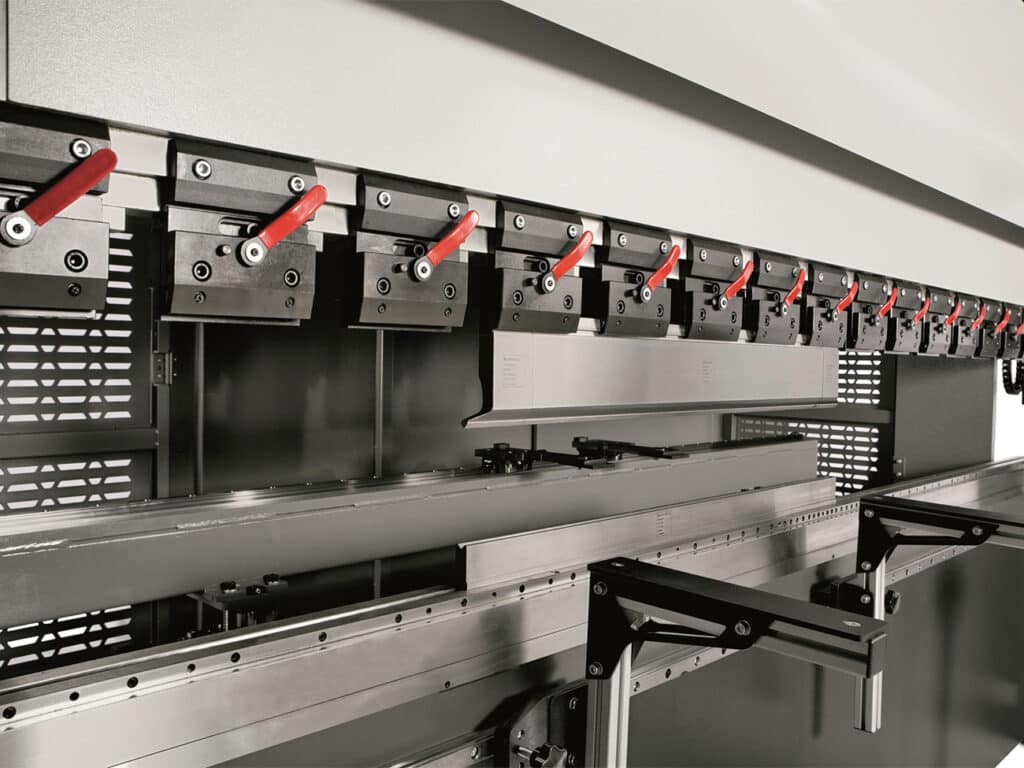

Thanks to this Xpress, Bystronic's innovative bending technology therefore comes within reach of a new target group: small workshops and medium-sized companies, as well as start-up manufacturers or companies for whom bending parts is not a daily activity. In the past, this customer segment bought used machines or low-cost systems. But the favorable purchase price all too often translated into poor quality. "Thanks to our Xpress entry-level model, we can now present this target group with a durable solution for bending workpieces up to 3 m long with a press force of up to 160 tons. The closed O-frame construction of this bending bench ensures high machine stability and allows for applications over the entire bending length. The modular design results in unprecedented flexibility and various tool clamps and back gauge systems allow this system to be adapted to the working environment. Compatibility with all other Bystronic bending systems also makes it easy to expand production in the future," explains area sales manager Salvatore D'Angelo. "Using the BySoft CAM offline software, manufacturability can be pre-tested. Thanks to the ByVision bending software, all process steps are clearly displayed on one 22" touch screen. This system is equipped with the same control used on the other bending machines in the range and ensures extremely precise operation."

'Pre-Owned by Bystronic'

The first machines of the Xpress series will soon be delivered and installed at customers in Belgium. In addition to this entry-level model, the specialist in laser cutting machines and bending machines offers this customer group another additional option, namely young used systems under the label "Pre-Owned by Bystronic. "By taking over Weber Laserservice, we acquired a lot of expertise in the field of used laser cutting machines," says Benelux sales manager Hans van de Meerakker. "These systems are completely overhauled by our people, the so-called 100-point check, and, where necessary, equipped with new parts, making them as good as new. This way, customers get a high-quality machine without having to invest heavily to do so."