Tube laser cutting specialist further expands capacity to larger size

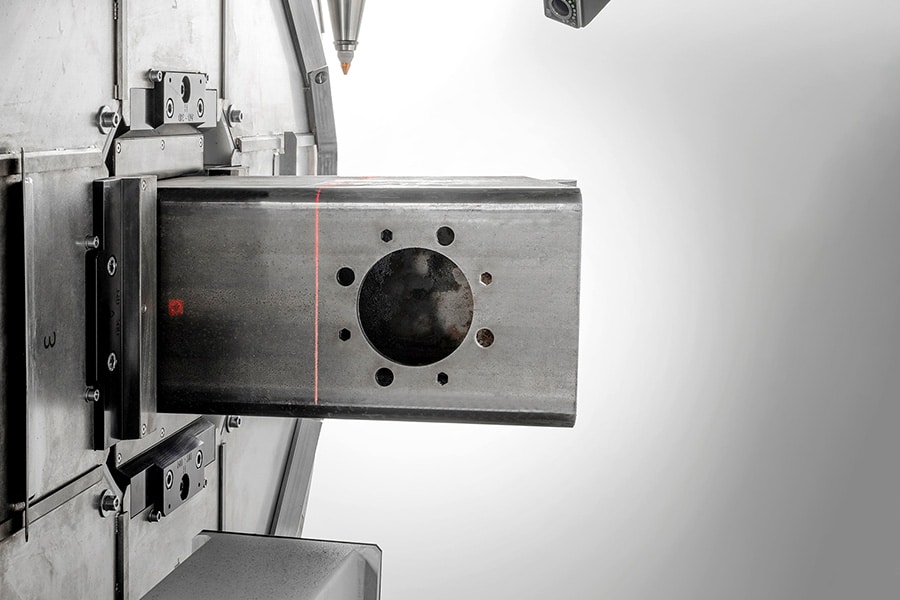

With the investment in an LT12 tube laser cutting machine from BLM GROUP, TCM - Tube Centre Marknesse - has recently started offering cutting capacity in tube, tube and profile up to 62kg/m and ø 305mm. Thus TCM fills the gap between 40kg/m and 62kg/m. The investment is the result of healthy growth and an increase in the number of customers from the north of the Netherlands. "We still see plenty of growth potential in this market. Especially because with the tube laser you can assemble constructions with one operation without the need for a tape measure," stressed director-owner Mark Hilderink. TCM is the first supplier in the Benelux to have commissioned an LT12 from BLM GROUP.

The large tube laser is the third the company has commissioned since its inception seven years ago. The LT12 complements the tube lasers LT8 and LT7 EVO that were commissioned by TCM in 2017 and 2019, respectively. "With these three different configurations we increase our capabilities and can now cut all diameters from small to max ø 305mm with the same speed, tight cuts and high reliability. In addition, we were looking for a backup for the LT8. With the investment in a third machine we now offer continuity, with which we have further increased process reliability for our customers," continued Hilderink.

BLM LT12: high productivity, large dimensions

The LT12 is one of the latest models brought to market by BLM GROUP since the introduction of the first tube laser over 20 years ago. With the LT12 tube laser, BLM GROUP fills the gap between the "mainstream" and large-format tube lasers (100/300 kg/m and max ø605mm) developed specifically for steel construction. "The LT12 is also as fast as the LT8 and certainly half as fast as other tube lasers on the market that can process up to ø305mm," Hilderink sees as a key advantage. "So cutting larger cross-sections does not come at the expense of cutting speed."

Efficient use of materials

With the 12.5 m chain or steploader, profiles in various profile shapes and lengths can be fed in single pieces or large numbers up to 12 m material length. Hilderink: "Nesting multiple parts from the standard trade size of 12 m of material is many times more efficient than from 6 or 8 m lengths. More efficient material use produces less waste and leads to a cost advantage for the customer. Moreover, this tube laser features scrap efficiency, which allows the material to be utilized down to the last 113 mm, thus greatly reducing residual waste."

Sufficient growth potential for tube laser cutting work

According to Hilderink, the market potential for tube laser cutting is still high. "Mainly because that you can make smart connections with the tube laser, where a tube end fits exactly into another part and thus can be welded directly to the right position without any fitting and measuring. So the profit is mainly in the composition. Yet we still have to explain these possibilities. Apparently, many engineers still think in the old processes. So there is still a lot of work to do on that point."

Internal logistics optimized

Simultaneously with the investment in the third tube laser, TCM doubled its production space, creating room to optimize internal logistics. "In addition to efficient cutting, efficient material flow is just as important. Material unloading, machine loading, cutting, machine unloading and disposal of cut parts now takes place in such a way that the loading of the machines can run simultaneously with the loading and unloading of the trucks." explains Hilderink further.

Long-term customer relationships

TCM's strength is that the company is able to bind customers from various industries and mostly from the region and Northern Netherlands for a longer period of time. "In this region there is a lot of shipbuilding and machine building for the agri-sector to which we supply a lot. And also all the companies that assemble and weld themselves. The fact that we keep the communication with the customer open, by thinking along with them where necessary on manufacturability, helps in the contact and has so far resulted in more work per customer. Making a profit is not the goal, but creating a long-term customer relationship," concludes Hilderink.

Heeft u vragen over dit artikel, project of product?

Neem dan rechtstreeks contact op met BLM GROUP Benelux BV.

Contact opnemen

Contact opnemen