Software makes metalworking even more efficient

Jörg Machines in Dodewaard is a household name in the Netherlands and Belgium. The addition of smart software gives metalworking customers in, for example, installation, roofing and facade construction the opportunity to work even more efficiently. Reinhard Reincke: "If you think along, deliver quality products and service, customers know they can trust you. Also when it comes to steps that improve the efficiency of craftsmen and companies."

Jörg Machines is both developer and manufacturer of its own sheet metal working machines and exclusive importer of several major European machine manufacturers. Some examples include Schechtl, Schlebach, Dener, Nosstec, Ekicontrol and Asco with the Variobend and Slinet machines. Jörg Machines operates as a one-stop shop for customers and offers comprehensive service and maintenance for new and existing machines, also remotely. Jörg Machines supplies the tools companies in the metalworking industry need, such as press brakes, longitudinal presses, double-benders and machines for automatic coil processing. It also has a group of permanent service technicians who can provide on-site or online support.

Embracing convenience app

The popularity of the combination between a good machine and automation is growing rapidly right now, observes Reincke. "If you go for the convenience of an app, it is possible to draw in profiles and transfer them directly to the machine. By combining technology and ease of use, we help customers work more efficiently."

Easier and more efficient

The possibilities of automation are far-reaching and applicable to a whole range of companies. Reincke: "Think of companies in the installation sector and companies active on construction sites. It's about benefits for more than just entrepreneurs in mechanical engineering. With the current software, you can prepare something easier and work faster and more efficiently. That means saving time. Moreover, if you as an installer have to measure something by hand, sketch it, draw it over and send it to the office where someone else calculates it and adds a price, the chance of mistakes is too high." Facade construction also benefits tremendously from automation capabilities, Reincke says.

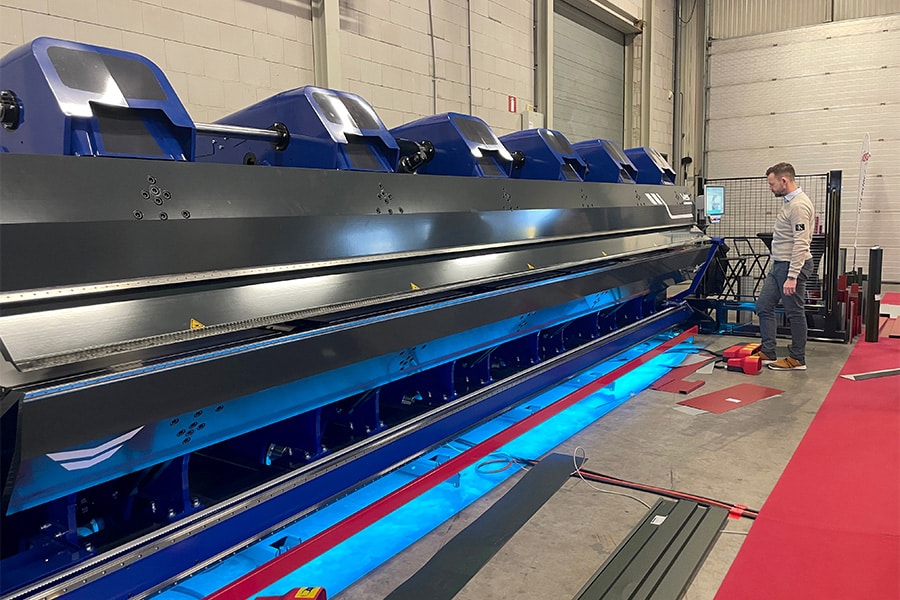

Overview at the House Fair

At a second edition of the in-house fair in February, the machines were all on display in action. From the impressive Variobend V2.5, Dener press brakes to Jörg's own machines for sheet metal working. The House Fair is not only an ideal time to establish contacts, but also to show customers and prospects the advantages of modern machinery. Reincke: "We notice that more and more customers are investing in new equipment, such as a motorized press brake equipped with CNC control. That's not even the latest development, but the most important thing is that the machine is equipped with easy controls. This allows entrepreneurs to reduce manual labor and work more efficiently. That is ideal when there is a shortage of skilled workers somewhere."

Giving customers access to improvements

In a number of areas, Jörg Machines is ahead of the competition. Reincke pinpoints two. "Roof and wall companies using our machines benefit emphatically from the new software capabilities, such as the use of apps for measuring dimensions. Users of the Variobend also clearly benefit." In addition, customers appreciate the fact that Jörg operates as a total provider, supplying the machines as well as installing the software and keeping it up-to-date. "This gives customers a single point of contact. We emphatically profile ourselves in the market as a supplier of 'machines that work.' But in today's practice, with the software, we add another important improvement."

Heeft u vragen over dit artikel, project of product?

Neem dan rechtstreeks contact op met JÖRG machines.

Contact opnemen

Contact opnemen