Higher powers and increasing competition from China

The popularity of tube laser cutting machines has gained momentum in recent years, and they are increasingly popping up in a variety of industries as an integral part of the production process. This rise is partly because tube laser cutting machines are able to replace several individual machines (including those for sawing, drilling, punching and cutting). More choice in power ratings, improved precision, automation integration and a smaller CO2 footprint also mean that tube laser cutting machines are serving an increasingly wider market. An additional and by no means unimportant advantage is that Chinese suppliers provide considerable price pressure, making it increasingly attractive to invest in tube laser machines.

Tube laser cutting machines lend themselves well to both standalone applications and integration into (automated) production processes. Automation, for example with tube feeders and/or robots, makes the process less man-dependent, faster and more cost-effective with, moreover, a smaller chance of errors. In addition, laser innovation and the introduction of cheaper laser sources with higher powers ensure that materials and larger thicknesses can also be processed that were previously difficult or even impossible to cut. These include materials such as carbon fiber, composites and ceramics, which creates new opportunities especially in sectors such as aerospace, automotive and medical & analytics. The CO2 footprint is also playing an increasingly important role in production, which laser manufacturers are also responding to with the development of more energy-efficient laser cutting systems.

Multi purpose

Tube laser cutting machines can be used to process different profiles indifferently whether they are round, rectangular or oval. Moreover, a tube laser cutting machine can cut a wide range of materials, including stainless steel, aluminum, carbon steel, carbon and composites. It can also be used for welding and engraving making the range of applications enormously versatile. The latest generations of tube laser cutting machines also often feature automated loading and unloading systems, reducing manual labor and improving safety. Tube laser cutting machines can be easily integrated into the CAD/CAM network with which, for example, machining and sheet metal working machines are also programmed. This improves quality and efficiency and minimizes the risk of errors. With 3D tube laser cutting machines, complex cuts can be realized including accurate chamfers, holes and notches which provides constructive advantages.

Top products from China

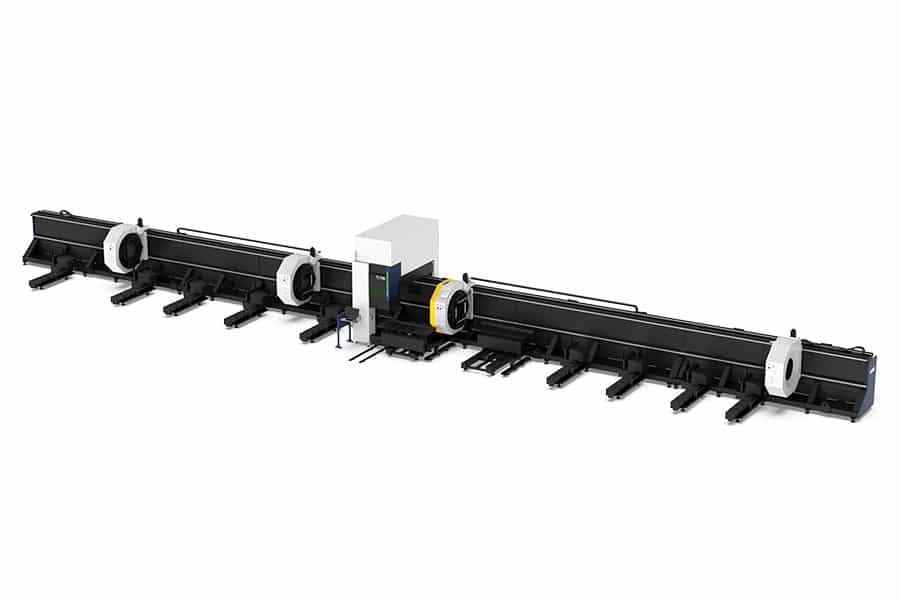

Landré in Houten is no stranger to the machining world. The company's history even dates back to 1863 and today the company specializes in the sale and maintenance of CNC machines for the metal and plastics processing industry. In addition to an extensive range of machining centers and laser cutting solutions, Landré is also a supplier of the very latest 3D printing techniques and advanced automation solutions. We asked Jan Floor van Egmond, director of the Landré Group, about developments at Landré in the field of tube laser cutting machines, of which his company carries the HSG brand manufactured in China. "The Western market still sometimes looks a bit suspiciously at machines from China," says van Egmond. "But HSG is in the top five A-brands and is hugely popular especially in the Far East while here in Europe their market share is also steadily increasing. A lot has happened in China in recent decades and a number of manufacturers are producing real top products, including HSG. They once started with tube laser cutting machines which is thus their core business. Then they also started producing flatbed lasers whose market share is now also steadily increasing. The program ranges from tube laser cutting machines for small diameters to large machines on which tubes up to 715 mm in diameter can be processed. In the area of profile processing, we have laser cutting machines that can handle profiles up to square 500 mm."

Higher powers

Tube laser technology has now been quite evaluated so that it is not just about cutting tubes to size, with which tube laser cutting machines replace sawing machines. Also, or perhaps especially, tube laser cutting machines make parts that fit into very complex assemblies with incredibly tight tolerances. One notable innovation is the introduction of higher laser powers. How does van Egmond view this? "That mainly has to do with the price development of laser sources. Previously, there was in fact only one dominant supplier of laser sources, so you had to count on about 50,000 euros per kilowatt of power. Just calculate what an 8 kW laser then cost. This limited the ability to market lasers with higher powers. These were simply unaffordable. Fortunately, other laser source manufacturers stepped into this market, causing prices to drop significantly. Now 1 kW costs "only" 5,000 euros, opening the way to higher powers. With flatbed lasers, you can cut at higher powers with compressed air and nitrogen, which is much cheaper than with oxygen. The advantage of a 40 kW flatbed laser, for example, is that it allows you to cut sheets 40 to 50 mm thick, including bevels. The high-power flatbed lasers thus displace the plasma cutting machines. With tube lasers, we see the higher powers especially with more complex and thicker materials. If you are only processing thin-walled pipe, a 5 kW laser is sufficient. Mind you, when cutting tubes you have too much rather than too little power."

Construction World

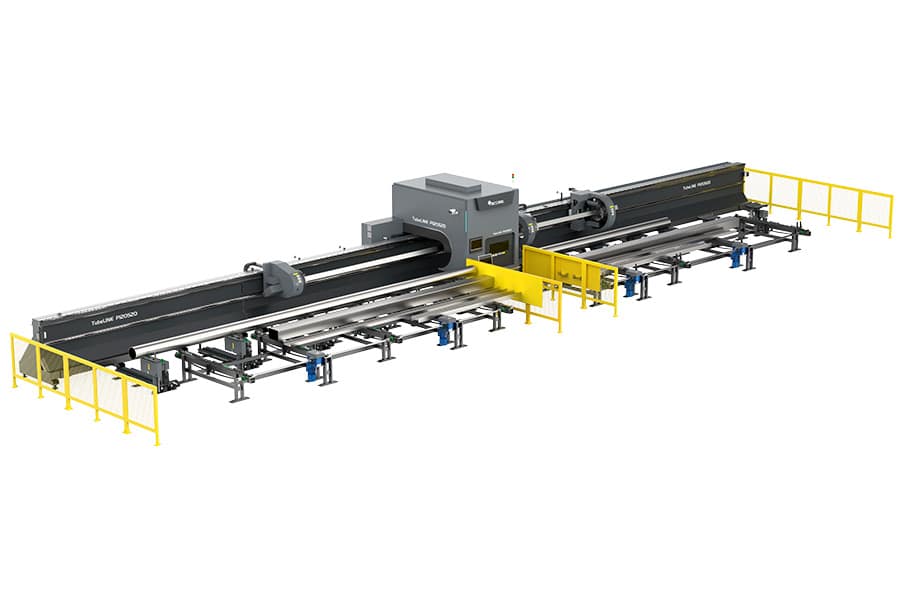

According to Maik Wensink, account manager at Tuwi, the fact that tube laser cutting machines have become cheaper means that they have also become an interesting option for construction companies. Tuwi supplies a number of product lines including the Chinese Acurl TubeLINE and the Durma HD-TC and Durma HD-TC Compact series produced in Turkey. "To meet market demand, we also source machines from China, where you can find incredible value for money with excellent quality and reliability. What is important here is that companies in the Benelux can count on Tuwi's service. Whereas laser cutting machines used to be unaffordable for construction companies, that has now changed considerably. A tube laser replaces traditional drilling, sawing, cutting, etc. up to certain dimensions. So you're now done in one go, which increases speed and quality enormously, while minimizing the chance of mistakes. You can also make complex cuts, making it much easier and faster to assemble pipes and profiles into a complete structure with smart plug-in connections so that you also gain profit there. Moreover, you can equip the machine with automated supply and discharge systems, where we supply solutions up to pipe lengths of 15 meters and diameters up to 520 mm.'

Good listening

Sébastien van Neste is laser cutting machine sales manager at Belgium-based LVD, and he explains LVD's tube laser cutting machine program. "We have two types of tube laser cutting machines in our program, namely the TL 2665 without bevel capability for capacities from 12 to 165 mm diameter and square 127 x 127 mm. In addition, we have the TL 8525. That is a machine with bevel capability for capacities from 20 mm to 250 mm, both round and square." For what applications are these machines suitable, or in other words, how do you make the right choice? Van Neste says: "In order to offer the suitable machine to the customer, it is very important that you first listen very carefully to exactly what the customer wants and really needs in terms of specifications. After all, it makes no sense to buy a heavy machine if, for example, you only process thin-walled tube in limited diameters. What is convenient is that both the TL 2665 and the TL 8525 are equipped with a semi-automatic front loader and 6 loading positions that allow you to process series efficiently. Because of their flexibility and universal applicability, our machines are of interest to numerous users. You will find them in suppliers, companies that realize machines and solutions for the horticultural and agricultural sector, but also in construction companies. So we do not focus on specific sectors, but rather aim for a wide variety of customers."

Efficiency and precision first

"For our tube laser cutting machines, we use powers of 4 and 6 kW," Van Neste says of the laser capacities. "For tube laser cutting machines, we currently don't see any added value in extremely high powers, as is the case with flatbed lasers. High powers make the cutting process in tube laser cutting machines unnecessarily complex and generally yield little profit. The most important issue in tube cutting is controlled precision. In fact, too high powers increase the likelihood of going right through!"

Optimally plan and monitor cutting processes

"In terms of automation, we offer our bundle feeder," van Neste says in conclusion. "This system allows for automatic loading of tubes into our machines directly from the bundle. Also important, our software packages allow you to accurately calculate cutting times and consumables, so you can optimally plan and monitor cutting processes."