The appointment for the metal industry

Professionals from the metalworking industry once again blew gather at the largest annual trade event for the sector: METAVAK. Last October 8, 9 and 10 at the Evenementenhal Gorinchem, they were able to get acquainted with all the latest developments, which should optimize and simplify their work. At the request of exhibitors and visitors, organizer Easyfairs successfully opted for a new layout, where companies were clustered by operation. Other new initiatives, such as the six demo areas and the centrally located knowledge theater, were enthusiastically received by the public.

The shift to early October and new initiatives, such as the division into segments, demo squares and the knowledge theater, were enthusiastically received by visitors.

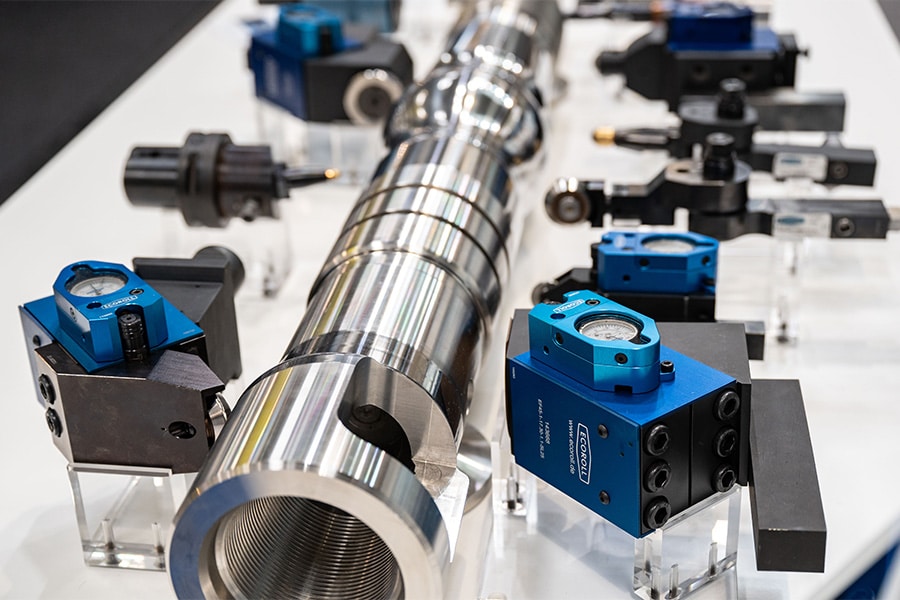

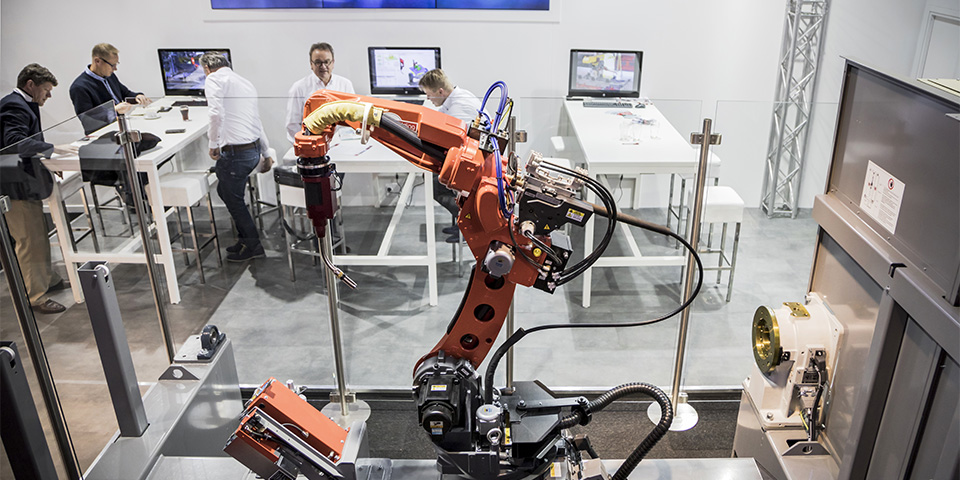

From October 8 to 10, the Evenementenhal Gorinchem once again opened its doors for METAVAK. During three days, over 220 manufacturers, importers and wholesalers of industrial production techniques, software, automation solutions, tools, and complementary products and services their latest developments: machining machines, sheet, tube and wire processing machines, surface treatment and cleaning machines, 3D metal printers, joining techniques, industrial tools, automation, CAD/CAM software, industrial fluids, maintenance and overhaul, measurement and control technology, personnel and training. They received the visit of the subject professional, particularly business leaders, buyers, project managers, production managers and operators from the metal products and base metal industries, plastics, government and education.

Segmented floor plan and six demo areas

To fit in better with the international trade fairs, the Dutch trade event for metal processors was moved from the very end of October to the beginning of the month. This immediately paid off, because for the first time in many years several major players in the sheet metal working market also participated. Fair organizer Easyfairs also took into account the comments made by exhibitors and visitors during the previous edition and opted for a segmented floor plan for the first time. "This time, the exhibitors were clustered according to processing and the exhibition area was divided into six different segments, each with its own color: machining, sheet metal working, automation, joining techniques, surface treatment and cleaning techniques as well as 3D printing," explains Fleur Bake of Easyfairs' exhibition organizer. "In this way, the fair was much more manageable, allowing visitors to search specifically for the companies that were relevant to them. In each segment, the smaller regional suppliers were among the bigger guys. In addition, each segment had its own centrally located demo area, where visitors could attend live demonstrations."

The exhibition area was divided into six different segments, each with its own color: machining, sheet metal working, automation, joining technology, surface treatment and cleaning technologies as well as 3D printing.

Knowledge Theatre - 'Visit the Future'

Another new initiative was the centrally located "Visit the Future" knowledge theater, where several practical, future-oriented knowledge sessions on production techniques were organized each day. "For example, on the first day of the fair there were several sessions around sheet metal working and on the second day knowledge sessions focused on joining and 3D printing, among others," Bake points out. "On the last day of the fair, the focus was on machining. Wilbert van der Heijden and Bart Heijenk gave three presentations on behalf of STODT on PMI for drawing and design, PMI for CNC production and PMI for the measuring room, respectively."