Automatic tool change for press brakes unburdens workers

With press brakes, installing tools takes up to seventy percent of the bending process. To speed up the installation time and to relieve the physical strain on employees, NTS CombiMetaal in Eindhoven - part of the NTS-Group - decided to invest in a new machine. The choice fell on Bystronic's automatic tool changer for press brakes. "Besides the ergonomic ease of operation, the bending software in particular was decisive for us," says managing director Peter van Hoof of NTS CombiMetaal.

As a specialized company in (opto-)mecha-tronic systems, modules and components, NTS CombiMetaal produces for machine builders worldwide. Although technically very high-quality products are created here, Van Hoof says the people are undeniably the company's greatest asset. "When purchasing a new machine, the ergonomic ease of operation for our employees is therefore partly a priority for us. This was also an important selection criterion when choosing the automatic tool change." According to the managing director, a careful selection process preceded this major investment: "In the end, this left three preferred suppliers, including Bystronic.

Trial assignment

Then a project team with software specialists and bending specialists, who will actually be working with the machine, visited all three suppliers to test the tool change and the software in practice. To find out what the machine is capable of, we also had all three candidates perform a sort of test job with a STEP and DFX file. For us it was especially a revelation how good Bystronic's bending software is. This software automatically generates programs, both from our laser cutter and the press brake. The intelligent sensors automatically recognize new tools and immediately integrate them into the magazine. This eliminates all programming efforts at the machine."

Physically relieved

In choosing Bystronic, the interchangeability of the software between different branches of NTS CombiMetaal also played a major role. "We especially work a lot with our branch in the Czech Republic, which has a similar production process," says Van Hoof. "Thanks to the universal bending software, the products we make here in Eindhoven can also be reproduced at our facility in the Czech Republic. This has also all been discussed in detail in our so-called sheet metal group, in which technical specialists from branches of NTS Group at home and abroad are represented." In terms of ease of operation, too, the Modular Tool Changer, as the machine from Bystronic is officially called, was ultimately the deciding factor.

Frequent tool changes

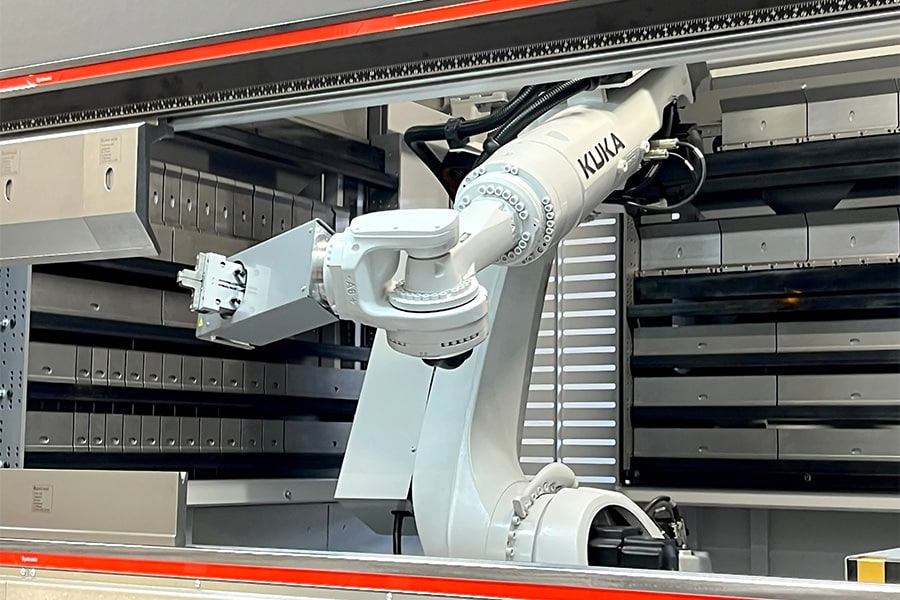

"Especially installing larger tools is physically demanding. This automatic tool change takes that heavy work completely out of the hands of our employees. For example, the six-axis robot has a load capacity of 25 kilograms and changes bottom tools up to size V120 and top tools with a height of up to 350 millimeters. In addition, the robot arm can rotate top tools 180 degrees. Because we produce many small series of, say, five pieces, we also have to change tools fairly often. That too can be done very quickly with this machine, which offers a lot of flexibility!"

Operator control

As another practical advantage of the acquisition, Van Hoof cites the controls for the operators, whose language can be changed. "For some of our employees, who have been in service for more than forty years and are somewhat less fluent in English, this is really a plus. One has the choice at the machine to choose the control language for each operator." The managing director is also appreciative of Bystronic's service. "If there is a breakdown, we expect it to be fixed as quickly as possible. Bystronic also has that covered thick and fast."

Heeft u vragen over dit artikel, project of product?

Neem dan rechtstreeks contact op met Bystronic Benelux BV.

Contact opnemen

Contact opnemen