At the touch of a button: Working more ergonomically and safely with machine tools thanks to gas springs and actuators from ACE

Anyone who produces 1 billion metal pens a year 24 hours a day must be confident that the production process runs perfectly. Then the trick is to ensure that even complicated steps are made as simple as possible. On the one hand to ensure a safe working environment and on the other hand to minimize downtime and maintenance intervals. KeyTec Netherlands B.V. succeeds well in this with the help of damping specialist ACE Stoßdämpfer.

Following the motto "We industrialize your ideas!", Keytec has been supplying precision metal and plastic components to customers around the world since 1999. As a business-to-business supplier, the Sittard-based company offers a wide range of product solutions for the automotive, energy and consumer goods industries. At production locations and sites in the Netherlands, the Czech Republic and China, the focus is on "design for manufacturing," short lead times and close cooperation with selected European and Asian tool manufacturers and partners in industrial automation, including ACE Stoßdämpfer. In addition, the Limburg-based company specializes in surface treatment and assembly by deep drawing, injection molding and related technologies.

Wanted: greater ease of operation in metal processing

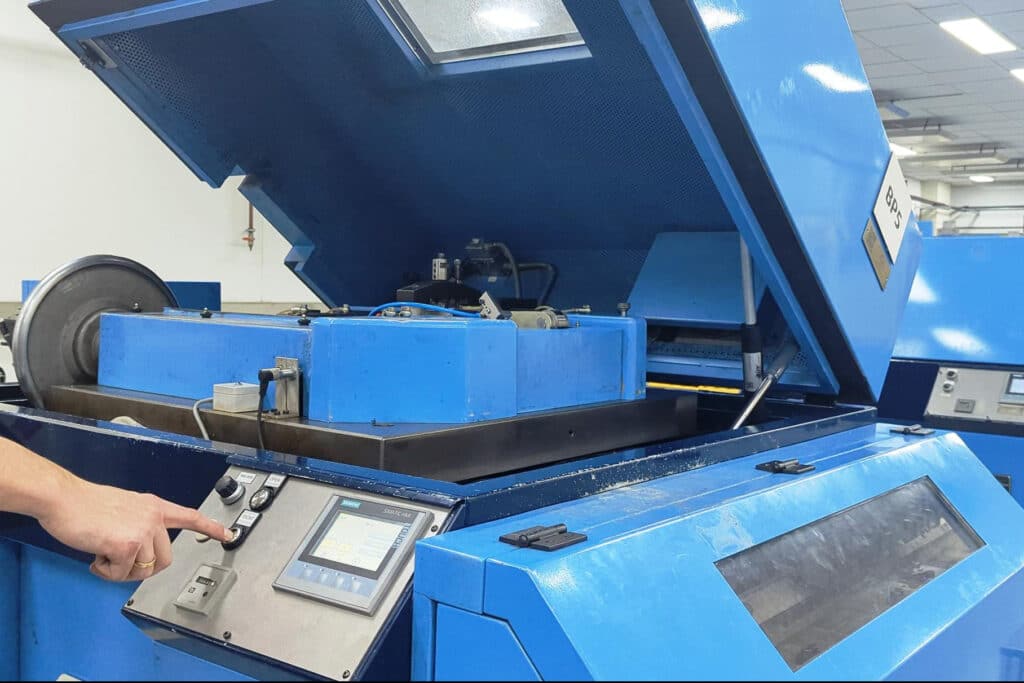

For various customers in the electronics industry, KeyTec performs a number of work steps for the production of batteries. These batteries contain special pins, about 1 billion of which are produced annually in Sittard in various designs. This requires machines that process wires precisely and guarantee uniform quality and high productivity. Processing takes place from the coil, with straightening, cutting and cold forming taking place in the machine. Once per shift, i.e. every eight hours, these machines are supplied with new coils by staff. This requires opening the hoods of the machine, which weigh about 45 kg each. This is also necessary regularly when the machines need to be cleaned or, in exceptional cases, during breakdowns when the inner workings of the machines need to be checked.

Extra muscle thanks to gasveren

The hoods are so heavy because, for health and safety reasons, the enclosed machine housing must also insulate sound well. In addition, the integrated drives, electronics and central lubrication system must be easily accessible to the maintenance team from all sides. For this, two industrial gas pressure springs of type GS-28-200-EE-920N from ACE at each hood take care of this. These ready-to-install, maintenance-free gas springs are long-lasting and filled with pressurized nitrogen gas. With an initial extension force of 920 Newton per gas pressure spring, they reliably support the muscular strength of personnel when opening and closing the hoods. From an ergonomic point of view and to further relieve the burden on the employees, KeyTec's technicians inquired with ACE's sales engineers about further possibilities to facilitate the opening and closing of the hoods and to modernize the machine tools used in a simple way.

Found: Industrial POWERISE® combined with gas springs

Industrial POWERISE®, a product series of electromechanical actuators developed by Stabilus, ACE's parent company, has been used for many years as actuators of tailgates of various automotive brands. The Industrial POWERISE® was adapted and perfected for industrial applications by the technical teams of ACE and Stabilus in recent years. Thus, in combination with the gas pressure springs already installed, the components are also suitable for the 45 kg heavy hoods of the machine tools in Sittard. The heavy hoods sometimes made operation for the operators heavier than ergonomically desirable. The additional drive type IPR35-V-24A-200-8-65C proved to be the most suitable to increase the ease of operation and ease the work for the personnel.

Once mounted and powered by either a 12 or a 24-volt connection, the Industrial POWERISE® makes reliable lifting movements of 200 mm in length at a spindle pitch of 8 mm per revolution at the push of a button. In this case, lifting and lowering is done in conjunction with the gas pressure springs with an additional force of 65 N from the built-in actuator. Through an analog interface, the movement of the hood was programmed exactly to the customer's requirements.

True all-rounder

The new actuators from ACE are available with spindle pitch between 2 and 25 mm and can lift, lower and position moving parts with forces between 250 N and 4,000 N at the touch of a button. With a stroke length between 50 mm and 350 mm, the Industrial POWERISE® can be used for a wide range of applications, such as opening and closing hoods, flaps, shutters, doors or gates, in both horizontal and vertical directions. In addition, the Industrial POWERISE® can be used as a positioning system. Since the noise level of the drive is only 55 dB (A), Industrial POWERISE® ensures that machines can operate quietly. An additional advantage in the aforementioned application is that the combination with gas springs from ACE relieves the drive, allowing higher weight. This enables faster, more ergonomic, safer and more efficient work at Keytec.

Heeft u vragen over dit artikel, project of product?

Neem dan rechtstreeks contact op met ACE Stoßdämpfer GmbH.

Contact opnemen

Contact opnemen