Unique welding process with patented wire feed technology

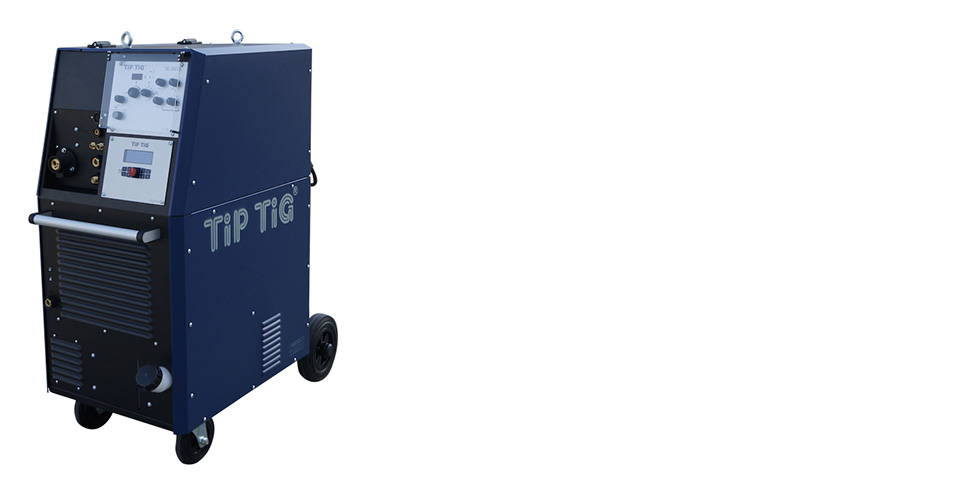

A positive wind is blowing through our manufacturing industry. Even in the field of welding processes and welding equipment, new developments are constantly being introduced. For example, today Welding Company is betting heavily on the TIP TIG welding process, a very unique HOT-WIRE TIG welding process with patented wire feed technology for manual and automated welding, cladding, orbital welding and aluminum welding.

TIP TIG is an innovative TIG process with dynamic wire feed motion. A TIP TIG HW (HotWire) welding machine is made up of a microprocessor-controlled welding inverter, a wire preheating device, a wire feeder with dynamic effect, a connection hose package and a welding torch. "The power source supplies the current for the Hot Wire, which is fed into the TIG arc by the unique TIP TIG wire feeder and water-cooled TIG torch. The welding arc is supplied by a regular TIG power source," says Patrik Huysmans, manager at Welding Company. "Unlike regular TIG or Hot Wire TIG, the TIP-TIG wire is mechanically superimposed by the patented wire feed motion, which creates a vibration on the welding wire."

Lots of benefits

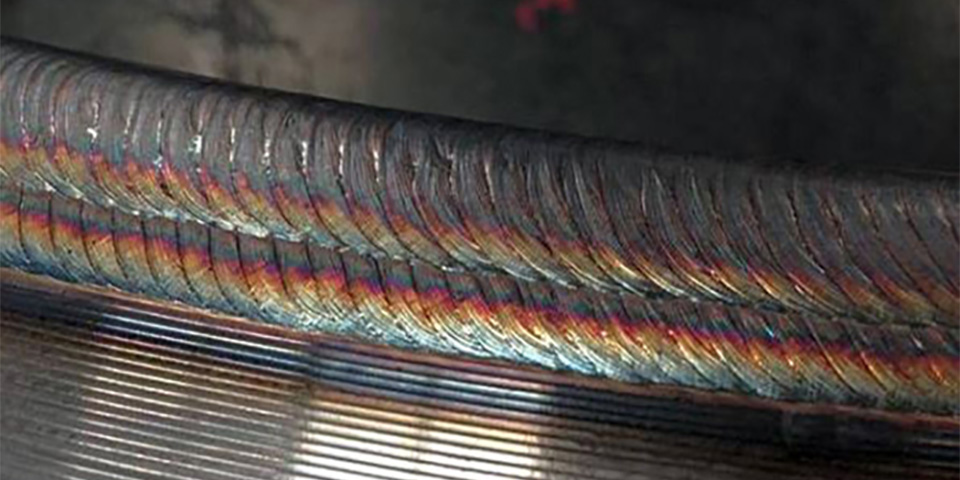

The TIP TIG welding process offers many advantages. Unlike manually pulsed MIG, regular TIG or automated hot and cold wire TIG processes, this process has the ability to deliver continuous high-quality welds with improvements in mechanical and corrosion properties. "Specifically, we weld faster so we have less heat input into the material, less distortion and less discoloration," Huysmans states. "In addition, there is a single welding process for each metal, weld and weld position. As a result, TIP TIG requires only two or three simple common weld settings for all applications."