The new Robot PLUS portfolio

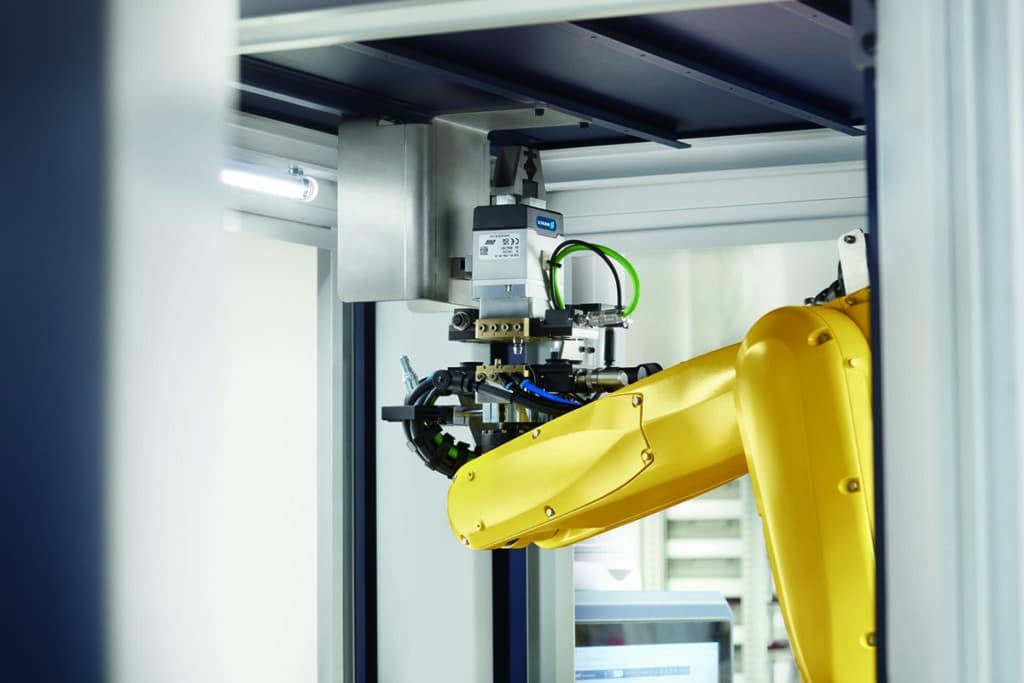

The new Robot PLUS portfolio from SCHUNK offers versatile options for flexible robot automation. It includes tool changers, compensation units and six-axis force/moment sensors, which can be combined in various ways with grippers from the extensive SCHUNK range. With this, SCHUNK makes flexible and efficient end-of-arm solutions available, all from one source.

Flexibility is the key to modern automation - and SCHUNK provides the right solutions. The technologically progressive company is expanding its future-oriented end-of-arm portfolio for robot applications with products manufactured in Germany. The portfolio covers the entire area between robot flange and end-effector and can be flexibly adapted to individual needs. With this, the company is continuing its course for the future, based on decades of experience in automation technology.

Tool changers: efficiently handling component diversity

With a tool changer, robots can flexibly perform different handling or machining tasks without additional changeover time. Grippers, tools and other enffectors can be changed quickly and easily - minimizing downtimes. The Robot PLUS portfolio currently includes three different products in this area.

For industrial applications, the CPS and CPB tool changers suitable. These change enffectors fully automatically via compressed air and offer a wide range of possibilities for media transmission via signal, compressed air, fluid and communication modules.

The CPS is a versatile all-rounder in which the changeover head (CPS-K) and adapter (CPS-A) are connected reliably and forcefully via compressed air and a ball-bearing locking mechanism. This system allows quick and safe changing of grippers and other tools, with a load capacity of up to 1,000 kg. Thanks to hardened steel in all functional components, this system is ideally suited for harsh industrial environments. The series includes 18 build sizes, providing the right changer for every robot. When replacing an existing SCHUNK changer, reteaching is not necessary, as the CPS is fully compatible.

The CPB offers efficient tool changers with maximum flexibility and process security. A special feature of this changer is the robust locking mechanism with pin. SCHUNK has used over 20 years of experience in stationary clamping technology for this and brought this proven system from the machine table to the robot. The power-locked, self-locking pin locking mechanism made of vacuum-hardened stainless steel offers maximum stability and a long service life. The integrated ISO interface allows quick assembly, simplifying commissioning.

The manual changeover system CMS is the ideal complement for a variety of tasks in production, handling technology or at assembly workstations. The compact system allows quick changeovers on the robot front. Thanks to proven lever technology, the CMS can be locked and unlocked without additional tools and with minimal force. The system supports a payload of up to 58 kg. Integrated sensor signals provide additional operational and process safety. Thanks to the ISO flange pattern, the CMS can be mounted on all common robot types without an additional adapter plate.

Modular compensation unit with large load range

The compensation unit AGM effectively compensates for tolerances in automated robotic processes. For example, problems in loading and unloading machine tools, inaccuracies in assembly processes or jams in bin-picking can be avoided. The modular AGM product family offers 23 build sizes so that no concessions have to be made to installation space. With numerous variants, users will always find the right solution. The AGM also excels in terms of compensation capability: movements in all directions (XY, Z, W) and their combinations (XYZ, WZ) can be compensated. The large load range is remarkable: from a few grams to more than 400 kg. Patented spring and air partons ensure reliable weight compensation even in horizontal or inclined positions. The stable and robust guides guarantee a long service life.

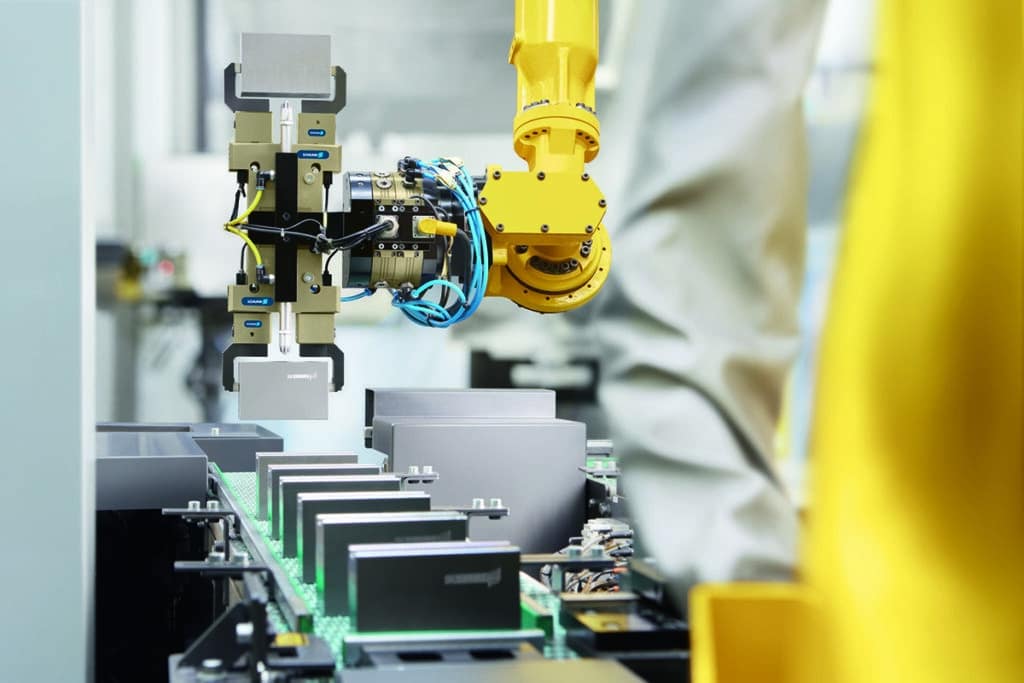

Precision counts: 6-axis force/moment sensors

Whether for quality control - for example in the production of batteries for e-mobility - process monitoring or applications such as grinding and assembly: the six-axis force/moment sensor FTS measures process forces and moments with high resolution and accuracy. The sensor reliably analyzes the working forces. Continuous monitoring leads to precise results and constant product quality. With protection class IP67, the FTS sensor offers reliability in nine build sizes, even under demanding conditions. The interface box with connections for EtherNet/IP, EtherCAT and PROFINET enables easy integration into existing systems.

With the Robot PLUS portfolio, SCHUNK offers versatile solutions for flexible robot automation. Thanks to decades of expertise in the development of sophisticated automation components, SCHUNK stands for maximum productivity, flexibility and efficient use of resources. schunk.com

Heeft u vragen over dit artikel, project of product?

Neem dan rechtstreeks contact op met SCHUNK.

Contact opnemen

Contact opnemen