Prima Power takes integration to the next level

The recent acquisition of long-time robotics partner Sistec AM complements Prima Power's technology integration know-how to further strengthen its unique customer-focused offering.

Sheet metal fabricators can now realize their potential through complete optimization of robotic cells and the widest range of modular solutions for automated systems - all from one partner.

One step forward.

Prima Power, progressive manufacturer of technology integration in the sheet metal processing industry, is taking another step forward towards full automation - the latest step in its "Evolve through Integration" strategy. The acquisition of robotics specialist and established partner Sistec AM, with its highly specialised expertise, enhances the integration of all our solutions to a superior level of optimization, both in terms of flexibility and performance.

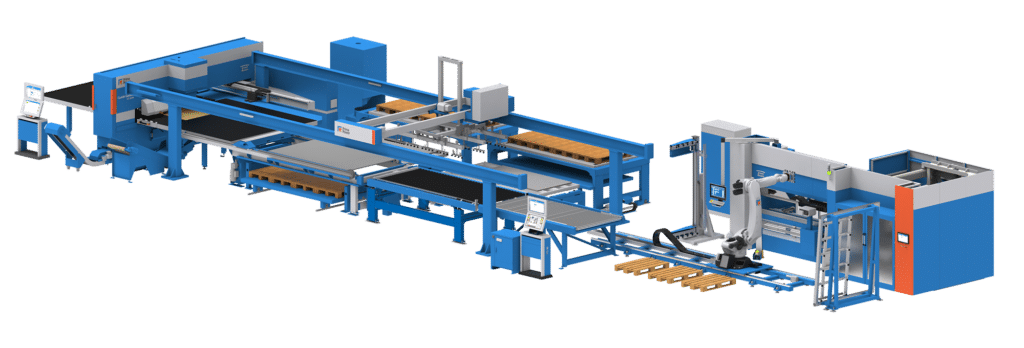

Our evolution remains focused on the specific needs of each company. The presence of a new internal Robotics Integration Unit unlocks the myriad combination possibilities of the widest range of sheet metal processing technologies, from advanced robotic cells to Flexible Manufacturing Systems that streamline the entire production flow. The benefits can result in increased productivity, more flexible and compact layouts, smarter handling and logistics, or wiser use of employee time - but there's more.

One, internal and complete.

In a manufacturing world that has long struggled with labor shortages, robotic technologies are fast becoming commodities: the future does not lie in robotics in itself, but in the quality and degree of robotic integration. In this scenario Prima Power is ready to make life easier for manufacturers. Regardless of their challenges, OEMs and job shops of all sizes can find the know-how and ideal technologies for their needs at one comprehensive partner. In essence, thanks to its complete range of sheet metal working machines and specialized Robotics Integration Unit, Prima Power occupies a rare position: the full in-house capability To always devise and deliver the solutions that better meet customer needs.

The process solver.

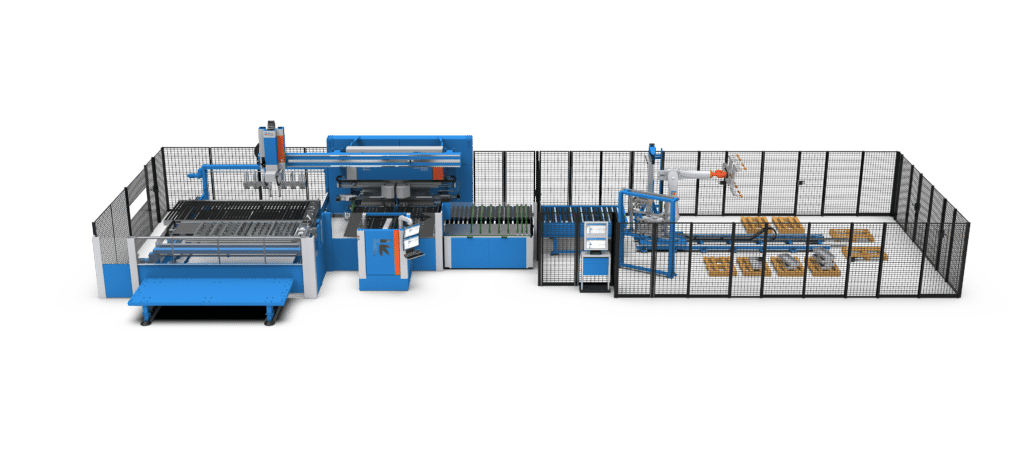

The acquisition ultimately reinforces Prima Power's strong process-oriented approach. Our new Robotics Integration Unit, born from the expertise of Sistec AM, combines with the broad portfolio of technology and software suite to enhance our role in industrial automation engineering elevate. Prima Power is the "Process Solver": the one partner to organize all production steps, from coil to assembly, and increase overall productivity. Robotic integration competencies, which drive all automation solutions, are particularly critical for Flexible Manufacturing Systems, where scalable sets of modular elements offer companies a range of decisive growth opportunities.

Optimal performance.

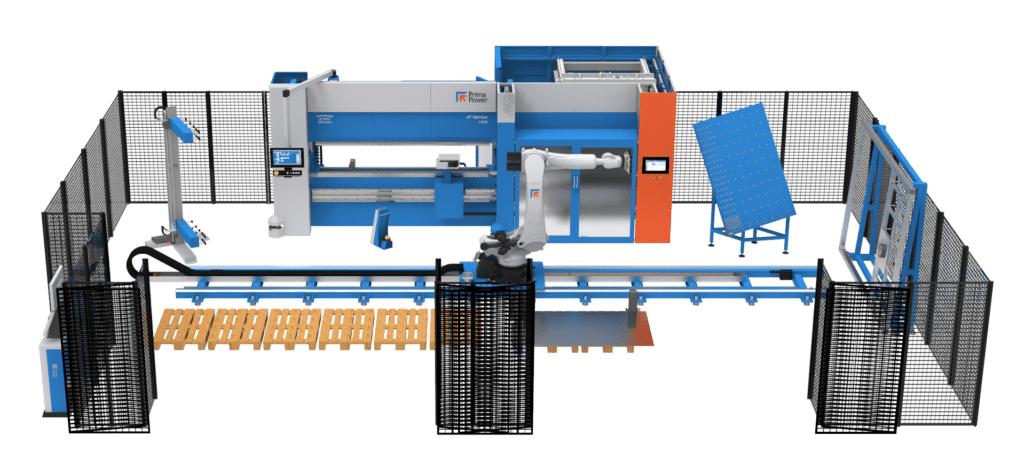

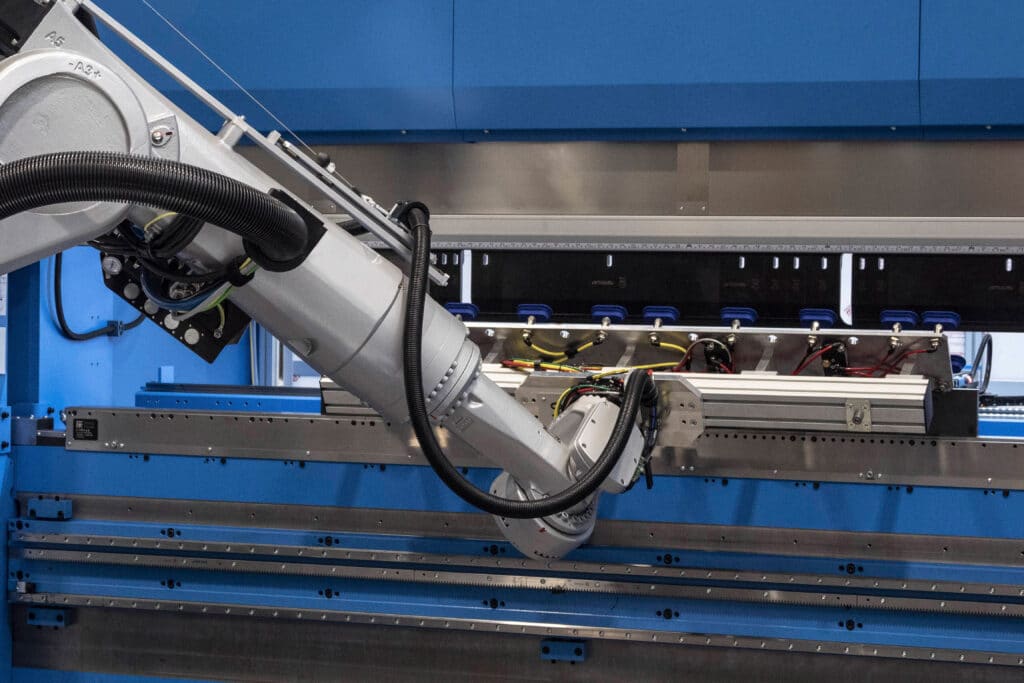

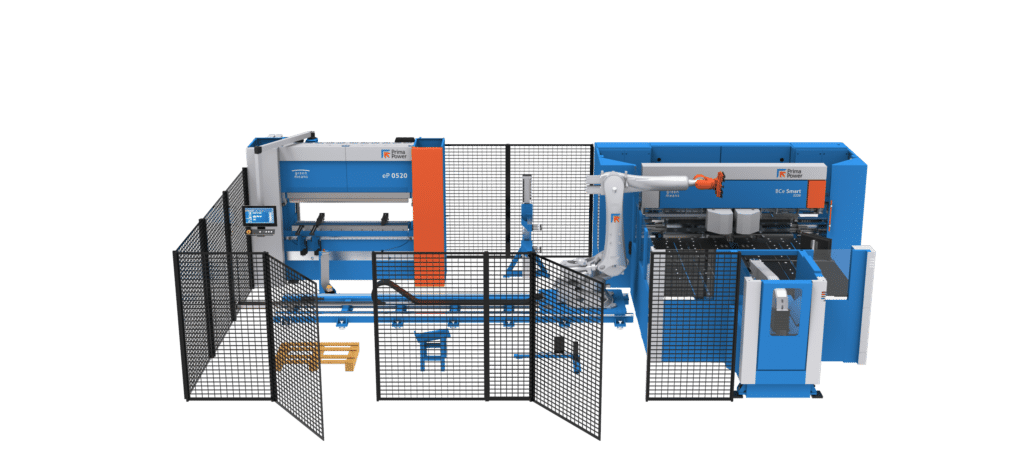

Our robotic bending cells are designed to transform sheet metal working by integrating advanced robotics with servo-electric press brakes and panel benders. This combination provides high repetition accuracy and a rapid return on your investment, making the profitable is for both small and large series. The flexibility of our stand-alone bending cells allows them to process a wide range of materials and thicknesses and adapt to a wide range of applications. Their modular design allows they are easily adapted and scaled up, so they meet the specific needs of different manufacturers and workshops, regardless of their scale. With fully automated operation, high precision and optimized layouts, our robotic solutions increase efficiency, reduce errors and simplify factory integration.

Unlock your potential.

Our robotic integration solutions are designed to deliver greater efficiency, flexibility and productivity in sheet metal production. By seamlessly combining anthropomorphic industrial robots with a wide range of technologies in robotic cells or complete flexible manufacturing systems, Prima Power's solutions optimize every stage of production, from material handling to assembly, while providing a compact, scalable and powerful system design. Our in-house Robotics Integration Unit specializes in creating Process-oriented solutions that simplify and optimize production flow. These solutions enable manufacturers to streamline production flow, reduce cycle times and improve overall output. Benefits to end users include fully integrated material handling automation, flexible and modular configurations, smarter use of personnel, optimized layouts and improved efficiency. Prima Power's robotic integration solutions offer extreme versatility and handle a wide range of materials and thicknesses. Thanks to the modular framework, these solutions are easily customizable and scalable, making them can be adapted to the changing needs of companies in different sectors and sizes, and their full production potential can be exploited.