Flexible tool handling for robots

SCHUNK has recently further expanded its End-of-Arm portfolio with future-proof solutions. One of the highlights in this is the new tool changer CPS, which enables the automated changing of end-effectors at the robot. The technology pioneer thus opens up new possibilities for versatile robot applications with short change cycles.

Flexibility as a key to success

Flexibility is essential in automated manufacturing. The increasing diversity of process steps requires agile cooperation of tools and systems. Thanks to a changeover system, robots can perform diverse handling and machining tasks flexibly and without additional changeover time. Downtimes are thus reduced to a minimum. The new SCHUNK tool changer CPS is a flexible all-rounder for automatic changing of end-effectors at the robot.

Flexibility made in Germany

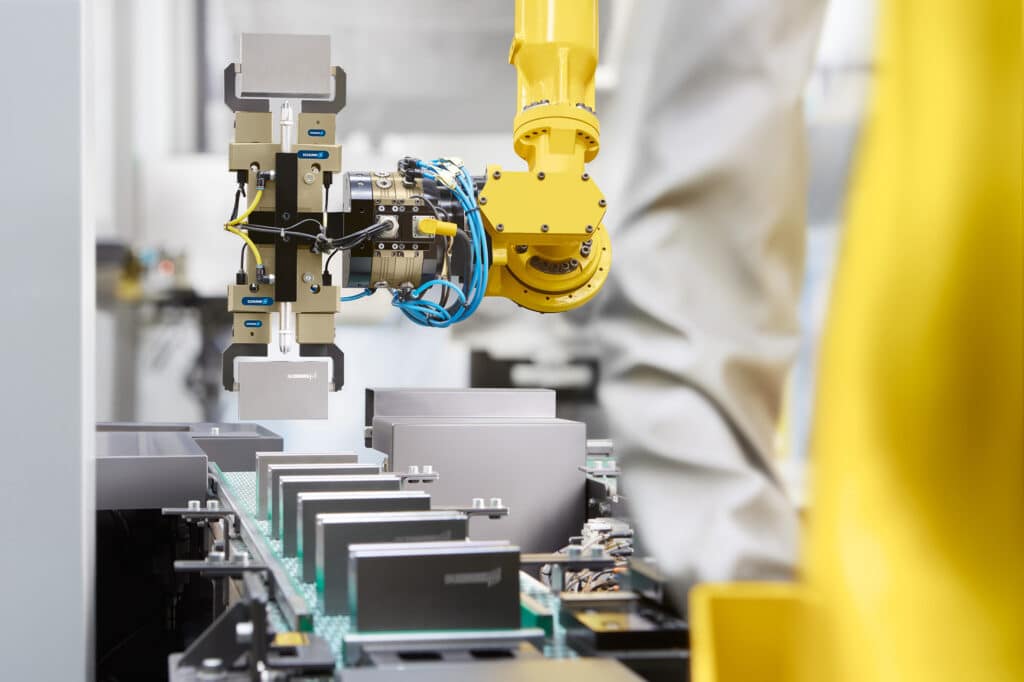

Grabbing raw parts magnetically from a tray and then loading and unloading them with a pneumatic double gripper in one operation - this can be done fully automatically by a robot using change systems. In developing the new CPS tool changer, SCHUNK deliberately chose versatility. The pneumatically driven system allows fast and process-safe changing of grippers and other tools, up to a handling weight of up to 1,000 kg at the front. The series includes 18 different construction sizes, so that a suitable changer is available for every robot.

Focus on safety and efficiency

The CPS consists of a changeover head (CPS-K) and a changeover adapter (CPS-A), which lock into shape by means of compressed air and are process secure. An integrated spring minimizes backlash in the event of an unexpected pressure drop while providing self-locking. Optionally available sensors provide transparency in process monitoring by monitoring locking status and tool presence. In addition, a wide range of signal, pneumatics, fluid and communication modules enhance the functionality and application possibilities of the CPS system.

The tool changer can be used both on a robot and stationary, for example in clamping technology. Since the system is fully compatible with existing SCHUNK changer heads, no re-teaching is required when replacing them. Mounting the changer head on the robot is easy via ISO flanges or standardized adapter plates. Thanks to the use of hardened steel in all functional parts, the CPS is particularly robust and durable - even in harsh industrial environments.

Robot PLUS - More possibilities for robot automation

With the new Robot PLUS portfolio, SCHUNK offers extensive possibilities for flexible robot automation. In addition to tool changers such as the CPS and CPB, the wide range includes newly developed compensation units and force/moment sensors. Thanks to decades of experience in the development of sophisticated automation components, SCHUNK guarantees high productivity, maximum flexibility and sustainable use of resources.

Heeft u vragen over dit artikel, project of product?

Neem dan rechtstreeks contact op met SCHUNK.

Contact opnemen

Contact opnemen