Pulse welding goes digital: faster, better, healthier

Lastek is launching a pulse welding machine that works faster, gives better welding results and is also healthier for the welder and his colleagues. "We have made a strong commitment to digitalization. Digital technologies that everyone can work with right away. Logical operation, simple settings," says welding engineer Tim Wils.

The new generation is going digital. In real life, and also in the work environment. Lastek picks up on this with its latest addition: the Emigma Puls Digital. "That one doesn't just go digital. Where pulse welding previously had its strengths mainly in aluminum and stainless steel, this machine now also gives significant advantages in industrial construction," continues Tim Wils.

Emigma pulse

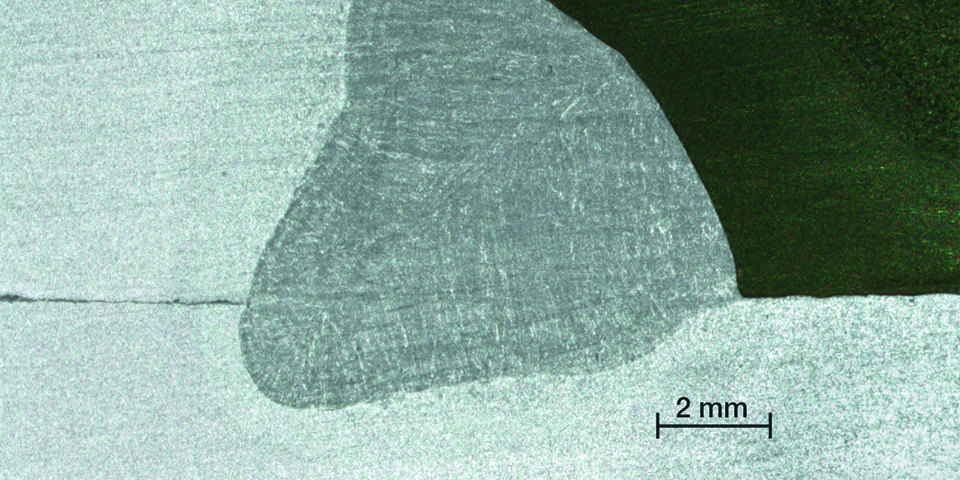

Better welding results

"The new technology provides better burn-in. This makes the weld stronger, using less material. The burn-in is also much better controlled, which gives a better view of the weld pool and causes less stress in the structure."

Faster

The Emigma Puls Digital can be set up faster and more precisely than a conventional pulse welding machine. It also welds faster (read: more meters of weld seam per hour) and requires virtually no reworking.

Healthier for welder and colleagues

The Emigma Puls Digital has a specially designed welding arc, with significant advantages. "Much less harmful welding smoke (up to 70% less), much less grinding dust (up to 80% less)and anti-splatter spray becomes completely unnecessary. And also pleasant: noise pollution from post-processing is largely eliminated."

Wireless control

The digital control system is ready for the future. Software updates can be done remotely: any authorized user can set up, monitor and adjust the machine. Wirelessly, via Wi-Fi.

View all details on Lastek's website.