Prima Power at Blechexpo 2025: fully integrated solutions and a world first

At Blechexpo 2025, Prima Power, specialist in technology integration in the sheet metal working industry, will present its strategic vision under the slogan "Evolve by integration." reaffirm with a selection of fully integrated solutions that help manufacturers meet the growing demand for automation, scalability and digital control in sheet metal working.

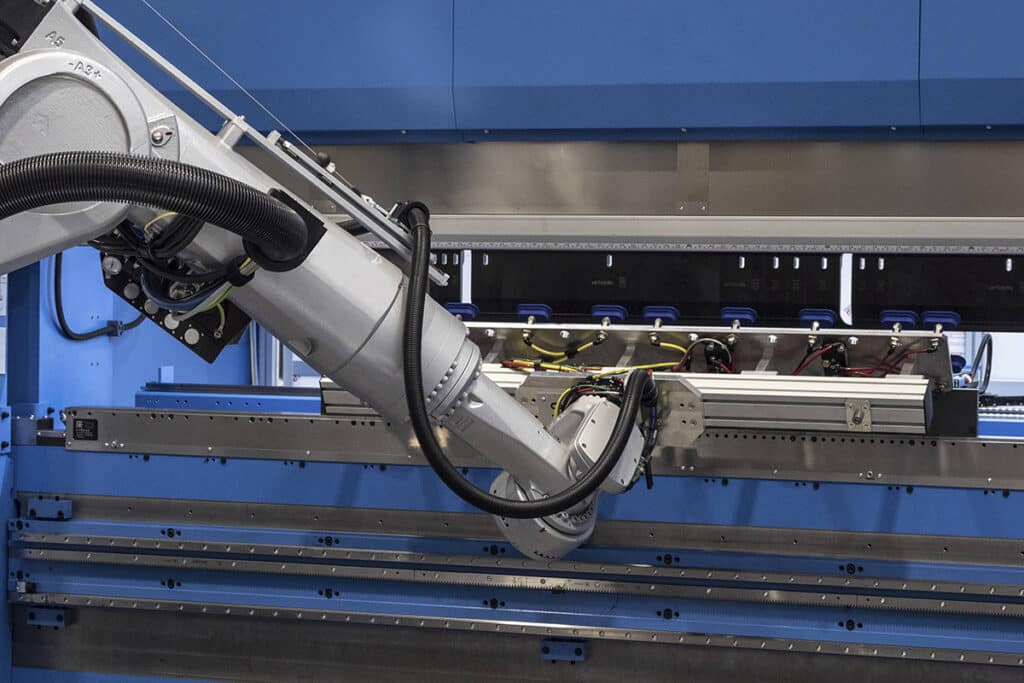

World premiere in the field of automated bending

Prima Power reveals a new robotic bending cell for compact spaces and high productivity, which is making its world debut. The system offers full automation, from loading to stacking, and features an advanced combination of technologies that ensure minimal footprint, fast cycle times and exceptional flexibility in part handling. This solution is the ideal choice for industries such as appliances, HVAC, automotive, metal furniture and industrial components, where small to medium parts are processed, from simple to highly complex geometries. Fully compatible with automated storage and logistics systems, this new solution supports unmanned production and simple Integration with FMS storage systems, such as Prima Power Night Train and Automatic Guided Vehicles (AGVs). It also enables flexible material supply from different sources. The new system uses the know-how of the Prima Power Robotics Integration Unit and is designed to grow with the customer from a stand-alone unit to a fully connected production cell.

Efficiency through integration - Combi Genius with LSR

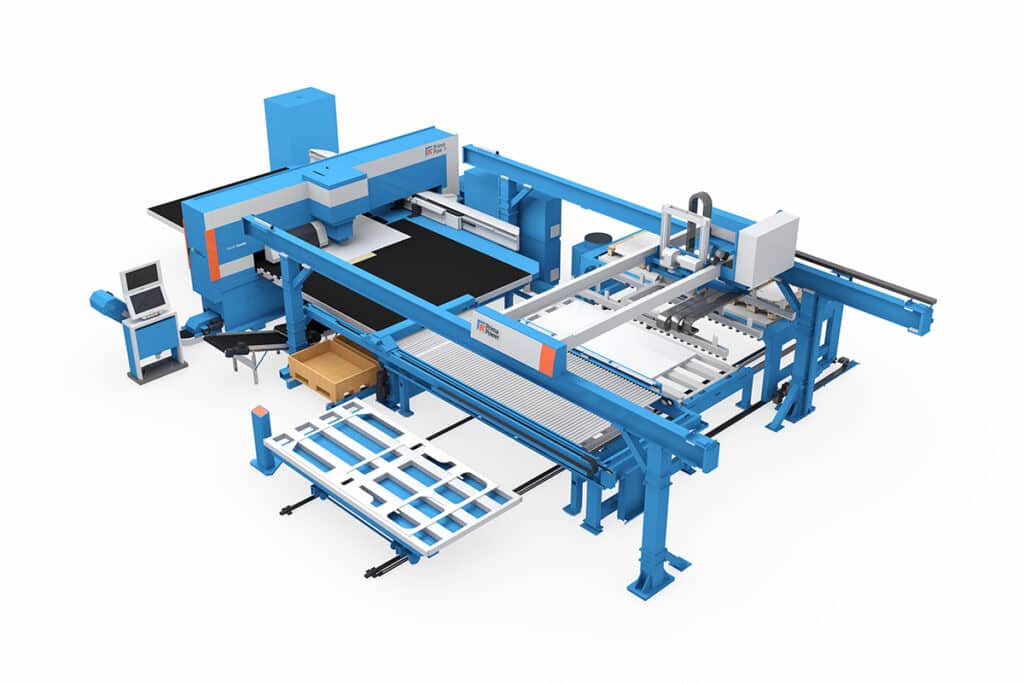

Prima Power will also be combined punching laser system with an automated loading and stacking robot (LSR) present. The Combi Genius combines multiple operations - punching, tapping, forming, marking and laser cutting - in one machine, providing exceptional flexibility and superior productivity, even with complex shapes and materials.

With its modular architecture, up to 400 turret tools and 6 kW laser, the Combi Genius delivers productivity and technical versatility of the highest level. When the Combi Genius is connected to systems such as Night Train FMS or integrated with a panel bender, it forms the core of a complete flexible production system, which end-to-end process automation enables with minimal manual intervention.

The integrated software ecosystem

The digital framework of Prima Power's offerings is the all-in-one software suite, which efficiently connects machines, data and processes. This integrated ecosystem enables continuous production, including programming, monitoring and analysis. At Blechexpo, Prima Power will demonstrate how fully integrated software that communicates between different production stages and technologies, enables smarter decisions and greater efficiency.

Prima Power's presence at Blechexpo 2025 underscores the company's commitment to further develop integrated technologies for sheet metal processing. The solutions on display demonstrate how automation, modularity and a common digital ecosystem can support manufacturers in responding to changing production needs. Evolve through integration.

Visit Prima Power in hall 3, booth 3201.