New bending benches: from bottleneck to streamlined production

Anyone looking for a custom store fitting has known for years that Zele is the place to be. There, Glotec keeps pushing the boundaries with innovations that serve customers at their beck and call. This is only possible thanks to an extensive in-house machine park. Where bending used to be the bottleneck, two new Xpert bending machines from Bystronic now guarantee streamlined production.

The in-house machinery gave Glotec the wings to serve customers at their beck and call and even more focus on innovative developments. (Image: Skinn Branding Agency)

Since its inception in the 1970s, Glotec has specialized in store fixtures and metal displays. But the company really came into its own when the Talpe family put its lend behind it. First father Boudewijn, but for some time now his two sons Kristof and Pieter have been at the helm with him. "The acquisition of a metalworking company has played an important role in our growth story. Everything we do is customized. Without it, we could never guarantee that flexibility with the same short lead times," Kristof Talpe points out. "Having our own machinery gave us the wings to serve customers at their beck and call and even more to innovative developments." One latest novelty, for example, is intelligent, interactive drawer cabinets. A strong example of technical ingenuity. The success culminated in 2016 in a new building that brought the total company area to 7,000 square meters.

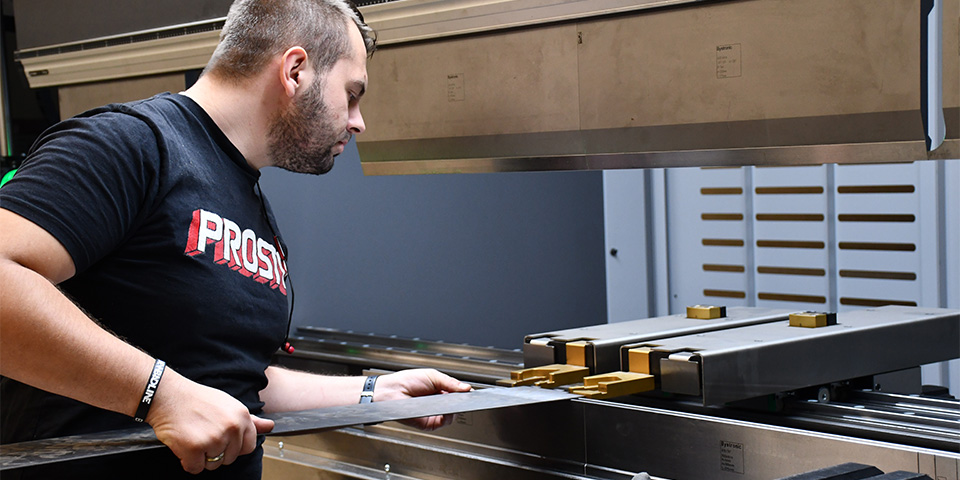

Operators soon abandoned the old folding benches to work with the new technology.

Software makes the difference

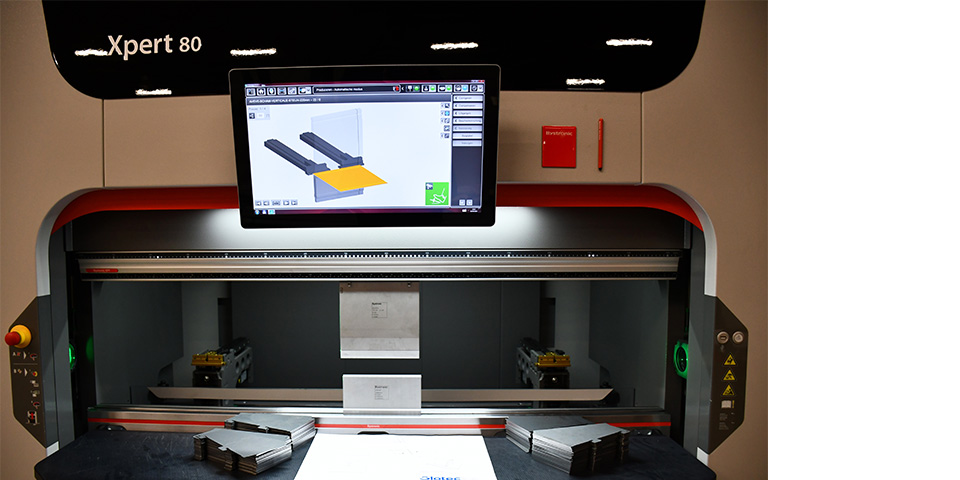

Huge investments have also been made in the machinery in recent years. The most recent newcomers to the production floor are two new bending machines from Bystronic. "Speed was not a crucial factor in this decision," Talpe points out. "For us it was important that it was up-to-date bending technology that could communicate with our software. After all, until then, the programming of the pieces was still done on the bending benches, which required a lot of preparation and knowledge. By taking that away from the operator and preparing the bending program directly from the 3D drawing in the office, the bending bench would no longer be the bottleneck in our production." The fact that Bystronic's Bysoft software was already running to great satisfaction in production only made the choice for the Xpert bending machines easier. "The software really makes the difference compared to the other brands. In addition, these machines have the right gadgets to ensure both quality and flexibility."

The second Xpert has been working since the end of July and can handle 80 tons and pieces up to 1.5 m. It serves mainly for smaller bending work and excels in speed.

Outages reduced to a minimum

For larger work, a 3 m Xpert 150 ton has been on Glotec's shop floor since June. The pieces that pass the revue usually fall between 0.8 to 3 to 4 mm. Talpe: "The active crowning and angle measurement on the bending bench ensure that we have very little rejects. That used to be a problem because of the complexity of programming, whereas customization just calls for first time right." The second Xpert has been up and running since the end of July and can handle 80 tons and pieces up to 1.5 m. "This one serves mainly for smaller bending work and excels in speed. With its 1.2 m, the bending bench it replaced was actually just too small to handle all the work for this. That has now been remedied and with its six axes this Xpert is very fast. The camera contributes even more to this because it allows for automatic height changes," Talpe adds.

Operators immediately choose

The benefits of these Bystronic bending machines are crystal clear to Glotec. "The bottleneck has been eliminated, everything now runs streamlined in production. We have to bend fewer test pieces and also spend less time programming. In the office, but just as much at the machine, should a piece need to be inserted quickly. That gives us the profit needed to be short on time for customers. Incidentally, the old bending benches are still here, as a backup should we need extra capacity. But the operators quickly abandoned them to work with the new technology," Talpe concludes.