Maximum productivity and flexibility in any automation

SCHUNK at the automatica 2025

At automatica 2025, SCHUNK is presenting its comprehensive portfolio for intelligent automation - from standardized components and complete solutions to customized engineering. The focus is on maximum productivity and flexibility in industrial production. The international leading trade fair takes place under the motto "Insights. Impulse. Innovations." from June 24 to 27, 2025 in Munich.

The increasing demands for efficiency, quality and sustainability call for future-proof solutions in production. This year's edition focuses on how intelligent automation and robotics are shaping the future. This is where SCHUNK fits in seamlessly with its trade fair appearance: the company supports its customers as a reliable partner with a broad, intelligently connected portfolio. With a clear technology strategy, SCHUNK strives to enable flexible and sustainable automation at every level and in every production environment - today and in the future.

"Because we deeply understand our customers' needs and processes, we can offer precise solutions," emphasizes Johannes Ketterer, COO/CSO of SCHUNK. "From standard components and customer-specific solutions to turnkey applications, we offer exactly what is needed." This is also reflected in the solutions SCHUNK will showcase at automatica 2025.

Versatility for robotic applications

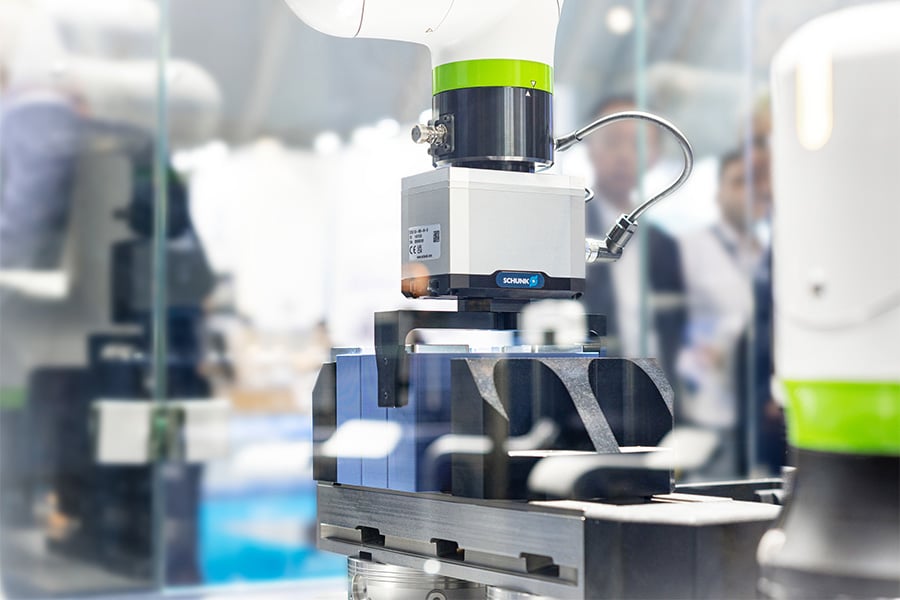

SCHUNK is continuously developing its range of robotic components in a future-oriented manner. With perfectly matched products, the company responds to the main challenges within automation and enables more efficient, flexible and productive processes. A fitting example of this is the modular compensation unit AGM - one of the versatile solutions for optimizing process reliability and protecting robots and workpieces from wear. It compensates for inaccuracies of a few grams up to 400 kilograms in all directions.

Three steps to higher productivity

Whether companies are just starting with automation or looking for customized solutions - SCHUNK offers appropriate support for every need. With a three-step approach, the automation expert accompanies its customers throughout the entire process: from needs analysis through validation - also in its own SCHUNK CoLabs - to installation and commissioning. SCHUNK supports implementation from standard components and modules to complete turnkey solutions. The goal is to sustainably increase productivity and make automation accessible to all.

Optimized engineering for all industries

For more complex requirements, SCHUNK, with proven engineering expertise and in close cooperation with customers, develops customized component solutions for different sectors - beyond the standard portfolio. One example is the aseptic exchanger, developed for applications in the pharmaceutical and food industries. It features pneumatic, electrical and mechanical passages, has a hygienic design with robust surfaces and meets GMP Class A requirements. Moreover, it is equipped with integrated sensors and requires no additional energy for interlocking.

In the field of e-mobility, SCHUNK is developing targeted automation solutions for handling battery cells - from handling during battery pack assembly to final assembly in the vehicle. The RCG gripper, for example, is specially developed for handling 46-mm round cells - both individually and for accurately loading entire cell clusters.

The SCHUNK engineering offering is further supported by digital tools such as the digital twin for planning and simulation. With these, customers can virtually plan, simulate and optimize their automation tasks. Partnerships with technology companies such as NVIDIA support the simulation and planning of complex automation projects.

Strong partners in humanoid robotics

Industrial robots and cobots are indispensable for future-proof automation of production processes. For these - and also for the next generation of robotic systems, the humanoid robots - SCHUNK offers suitable end-of-arm components with open digital building blocks. For example, the anthropomorphic 5-finger gripping hand SVH is available with open-source software as well as a digital twin. Thanks to decades of experience in flexible gripping technology and strong collaborations with industrial partners, start-ups and research institutions, SCHUNK thus opens up new fields of application - also outside the scientific context. What this looks like in practice can be seen in an impressive live demonstration at the SCHUNK booth in cooperation with NEURA Robotics.

Timo Gessmann, CTO of SCHUNK, elaborates on this topic during the automatica forum on June 24 at 11:30 a.m. as part of the panel "Humanoid robots: the next generation of robotics?"

What crucial role data plays in digitization and automation will be highlighted next on June 24 at noon by Henrik A. Schunk, Chairman of the SCHUNK Executive Board, in the panel "Manufacturing X: why industry needs a sovereign data environment."

Visit SCHUNK at automatica 2025: Hall A5, booth 401 & 501

Heeft u vragen over dit artikel, project of product?

Neem dan rechtstreeks contact op met SCHUNK.

Contact opnemen

Contact opnemen