Manufacturing efficiency means on-time deliveries and satisfied customers

A machining workshop aims to produce a certain number of parts delivered on time in the most efficient manner with the required level of quality. Traditionally, manufacturing companies defined efficiency based on return on investment. Success was measured by constant production of thousands or hundreds of thousands of pieces. And continuity of steady output with one or many machines was the goal. From that perspective, a machine was considered efficient if it functioned well and made parts.

Today, manufacturers are more often focusing on low-volume/high-mix production scenarios tailored to customers' changing needs. Batch sizes can range from hundreds to as little as 10 pieces. Even when all machines in a workshop are working continuously, however, customers may still have to wait for parts they ordered. Strategies based on high-volume production conflict with the flexibility and complex scheduling requirements of low-volume production scenarios.

In today's production environment, manufacturing is truly efficient only when there is a flexible balance between maximum production and timely fulfillment of a wide range of individual customer orders. The focus is on the end result: on-time delivery of products and satisfied customers.

Quality control

While balancing production and demand, manufacturers must take care to maintain product quality. Working with parts of unacceptable quality leads to forced changes in production schedules, wasted time and money, and delays in deliveries. Haphazard scheduling leads to production downtime and shuts down machines while shop floor labor costs multiply to fix the unforeseen problems caused by the interruptions.

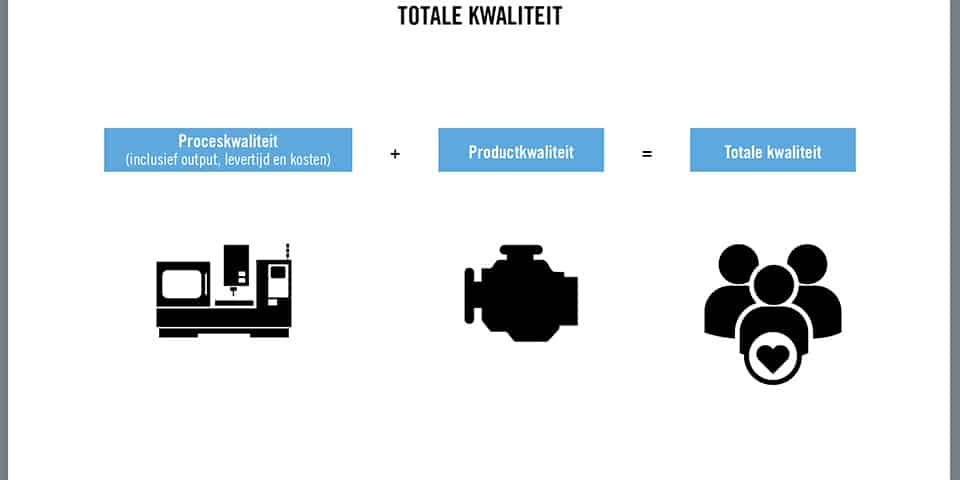

The quality of workpieces in manufacturing is generally measured by whether part size and surface finish requirements have been met. An additional quality criterion, namely on-time delivery, can be called process quality. The manufacturer must exercise such control over processes that planned production time is sufficient to complete the work and that products are delivered at the promised time.

Keeping customers happy versus making a profit

Machinery in a workshop may be in operation 100 percent of the time. But the workshop has failed if it does not deliver on time and customers become disappointed as a result and stop purchasing products from the workshop. Keeping customers happy is a primary goal, but focusing only on customer satisfaction can threaten profitability. Focus on the customer is essential, but a manufacturer must maximize its equipment while also meeting customer demands for parts volumes, quality requirements and delivery time.

Promises and planning

Successful manufacturing involves coordinated interaction of multiple groups within the manufacturing organization. One group promises customers certain results with respect to cost, quality and delivery time for the parts they order. The other groups in the organization -- including engineering, purchasing, shop personnel and administrators -- ensure that these promises are kept.

Different groups define efficiency differently. Machining personnel want to optimize individual machining processes to enable maximum output. Groups outside the technical machining process focus on improving system performance as a whole. Their analysis addresses topics such as overall equipment effectiveness (OEE) and labor productivity.

The heart of efficiency

Manufacturing efficiency can be described in basic biological terms: the heart of any manufacturing activity is the machining process. Although the heart of the body is indispensable, it does not work by itself. It is part of a system that works with the rest of the body and the brain.

If in manufacturing the heart is machining technology, then the body is the overall manufacturing organization - including engineering, business planning and management. The brain of the organization is the group of personnel who coordinate all elements of the system. However, the brain cannot simply decide that the heart needs to pump faster, just as a person cannot control his or her heartbeat by simply thinking it needs to happen. Similarly, an editing process cannot always be controlled from a rational perspective.

In today's world of digital technology and the Industrial Internet of Things (IIoT), people, especially young people, want answers and clear rules for controlling the machining process. Unfortunately, in many cases there are no rational rules, and it is necessary to accept, react to and solve the unexpected machining problems.

Unexpected problems and unskilled workers

In a perfect world, workshop personnel have the knowledge, skills and experience necessary to solve unexpected problems in the machining process. However, many workshop owners complain that it is difficult to have personnel who are adequately skilled. Training seems to be a solution to the shortage of skilled workers, but surprisingly, some workshop owners say that their training efforts are often wasted effort because employees do not exhibit a positive attitude when it comes to learning new skills. Owners report that in many cases where they offer technical training, workers believe they already know enough to perform their assigned work and do not need additional training. (See sidebar column)

Total manufacturing time

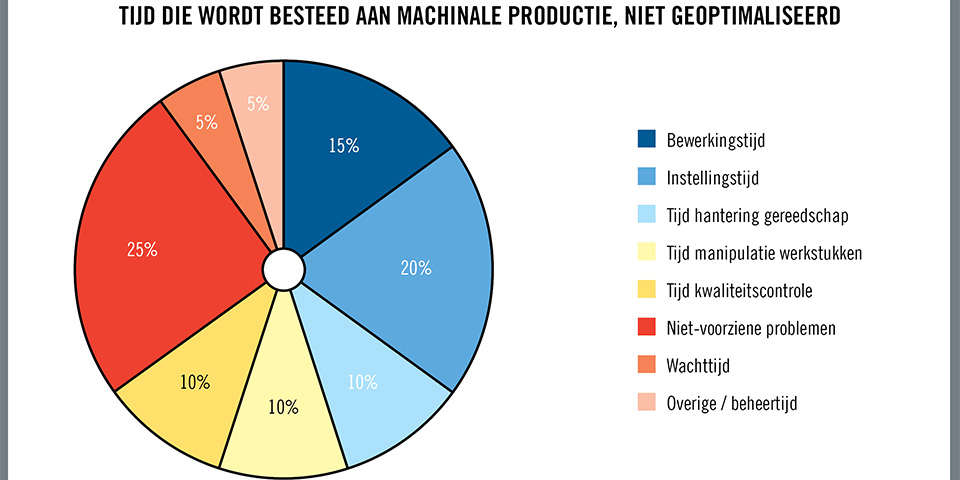

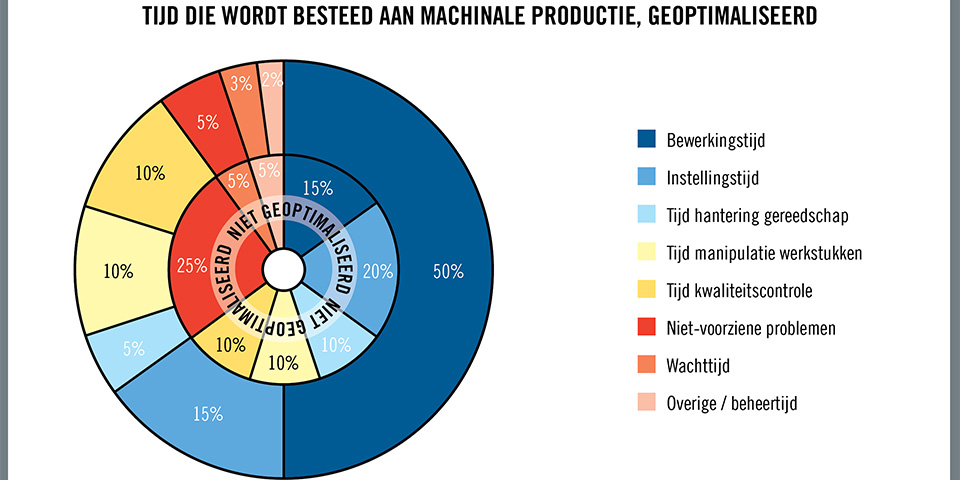

Analyzing a workshop's efficiency and eliminating waste can free up additional time for machining and therefore greater flexibility and responsiveness to customer needs. The total time required to manufacture a part is the sum of many individual activities. These include actual machining time, tool handling, workpiece manipulation, quality control, unforeseen problems, waiting, management tasks and others.

Some of the activities are important and cannot be eliminated, such as tool changes and workpiece manipulation. Workshops, beyond the required activities, must also devote time to contingencies such as schedule changes, quality problems and waiting for missing tools or workpiece materials.

In one particular case, a workshop evaluated a number of different machining activities for a part to determine the amount of time consumed for each activity (Figure 3). Actual machining time was 15 percent of total fabrication, while setting and waiting took a quarter of the time, and unforeseen problems, such as missing or delayed tools or stoppages to remove excessively long chips, accounted for another 25 percent. By reducing the time taken for unforeseen problems, setup time, tool handling, waiting and management, actual machining time increased to 50 percent of the total (Figure 4). That more time became available gave the shop more flexibility to tailor machining operations to specific customer job requirements.

Unforeseen consequences of time-saving efforts

As a result of a time-saving study described above, another workshop was able to triple the hours that spindles spent actively cutting parts. However, the workshop noticed that part production in turn did not triple.

Further investigation revealed a number of issues that contributed to this phenomenon. A key problem was that the original process time included deburring outside of machine time. The time-saving initiatives assumed that deburring could be performed more efficiently on the machine itself. However, when deburring outside the machine was moved to the machine tool, the overall spindle time increased because of the deburring activity. The situation shows that time savings in one area can lead to greater consumption of time, or a marked decrease in efficiency, in another area. The lesson is that operational changes must be considered in relation to the manufacturing process as a whole. It is a difficult balance, and there are no general rules other than to look for opportunities to use available time as effectively as possible.

Changing plans

Achieving efficiency and flexibility requires constant adaptation to changing production requirements. Changes often arise externally when a customer changes a product design or the number of parts required changes. The manufacturing shop must change its plans in response, but this must not result in an overall disruption in the shop or a disorderly response that causes further disruption.

When scheduling is disorganized, some workshops send work items through the shop in a random fashion and work is performed on every machine available, creating more problems. When scheduling problems occur, they can grow into a virus. A small disruption can quickly become big. And like a human virus, the disruption can be difficult to overcome.

The spare capacity option

Adding additional machining capacity is one way to increase efficiency and flexibility in the workshop. The concept of "spare capacity" is foreign to most workshops, and a workshop's finance department may support investment in new machining capacity but demand that the new equipment not go unused. They view a machine as a one or two million dollar investment and cannot understand that if the machine is purchased as spare capacity, it remains unused and regularly does nothing. But in reality, it does something important: it ensures satisfied customers. This machine is a useful backup that provides flexibility and fixes unforeseen problems.

In some situations, instead of purchasing a backup machine, a workshop will work with its own equipment until overload occurs and then enlist the help of a subcontractor. But if that subcontractor faces the same problems of too much work and insufficient staff, the responsibility is simply passed on to another party. It is extremely difficult to convince workshops to build spare capacity with the possibility that it will be used infrequently at best.

Long delivery times versus on-time delivery

Pressure to deliver on time can extend the actual fabrication time. If fabrication of a job takes a week under normal circumstances, but the customer wants an absolute guarantee of on-time delivery, a workshop might specify a two-week delivery time to create a buffer. In another case, when a customer needs a completed workpiece on a certain date, a workshop might start with two workpieces to have a backup during the process in case something unforeseen happens to the first part. These makeshift practices unnecessarily result in a lot of manufacturing time and high manufacturing costs and actually make the delivery time longer than what it would normally be.

Multitasking choices

Another, though expensive, way to increase efficiency and flexibility in a workshop is to use automation in the form of a multitasking machine and a pallet pool. A workshop can quickly switch an automated cell from one task to another and use the pallets to build and store future setups. Such a system can be built around a multitasking machine surrounded by workpiece pallets and accompanied by a tool magazine with multiple tools, all operated by a robot. In this setup, the day shift staff can set up the machine and pallets to handle a variety of parts and the night shift can produce the parts. However, this solution is relatively expensive and is not of an investment level that every company can afford.

Barriers to multitasking

An organizational barrier to the multitasking approach is that machines in factories are usually arranged by function, such as use of a separate milling department, turning department, etc. In many cases, it is better to organize machines by cells, with each machine group having certain process capabilities suitable for specific workpiece groups/families. Simply grouping machines by function also encourages shop personnel to describe themselves in a limited way, such as lathe operator or milling machine operator. Training operators to be multifunctional and to work with different machine types gives a workshop the flexibility to balance its own internal capacity issues.

Conclusion

When it comes to efficiency in manufacturing today, there is a strong emphasis on customer satisfaction in addition to finding the best methods of machining parts. Manufacturers must balance their efforts to consistently deliver in a timely manner with the need to be profitable. In addition to optimization of machining operations, the time available for machining parts can be greatly increased and can result in greater flexibility and efficiency when careful attention is paid to issues such as part and process quality, scheduling organized from the perspective of the manufacturing organization as a whole and constant analysis of the consumption of the elements of machining time.

Supporting a way of thinking focused on efficient manufacturing

Evolution of manufacturing strategies offers operators a range of new challenges. Highly automated machine tools, intuitive software and advanced cutting tools have reduced the number of manual tasks required of the operator. Unfortunately, a side effect of this advanced manufacturing technology is the tendency of some manufacturing personnel to quickly assume "good enough" with respect to their skills.

Many workshop owners have found that when some employees are offered training, they are not enthusiastic and feel they already have enough skills to do what they need to do. These employees do not have the mindset needed to grow and develop in the new manufacturing environment.

In Flanders, this way of thinking is described by the saying "What benefits candle and glasses if the owl will not see and read. The similar North American phrase reads "You can lead a horse to water, but you can't make him drink. In short, you can give people anywhere in the world the resources they need to achieve a goal, but if they don't want to participate, the effort is in vain.

In most workshops today, powerful hardware, tools and machining programs are already in place. It is the people who have become the crucial element of manufacturing efficiency. Along with advanced thinking, the ability to read the machining process is the special skill required today - not by working with a computer but by standing at the machine, listening and observing the process.

In general, the process indicates its own status, in the same way that a person can listen to his or her own heart and feel whether it is going well or not. That awareness is not calculated using a formula. It is essential to know what you want to see and what the favorable factors are in the process environment. Seco offers many forms of machining technical training, knowledge and support. When workshop employees have the right mindset, Seco is there to help them learn and apply what they need to be successful.