Making light work of heavy barrels

In chemical products, formula makes all the difference. For CRC Industries, this starts from a thorough knowledge of the product and its application. From its European headquarters in Zele, it produces no less than 250 different formulations, good for 14 million aerosols a year. In its production, CRC Industries gives top priority to safety and ergonomics. A Dalmec pneumatic manipulator was therefore installed in the mixing room last year. A feat of technical prowess because no other manufacturer was up to the challenge.

CRC Industries bvba (Corrosion Reaction Consultants) was created when Charles Webb came up with an innovative formulation for creep oil in 1958. Success did not stop there, also in Europe, and in 1975 the construction of a production facility in Zele began. One of the specialties is the use of CO2 "This has the advantage that the customer receives 95% active product in aerosol, thanks to its high pressure retention, whereas with liquid propellant it is typically 60%," opens production manager Marc Vereecke. HSE manager Freddy Remue: "The strength of CRC Industries has everything to do with product knowledge. We make and mix everything ourselves, so we know every type of product, whether it is lubricants, cleaners, anti-corrosion products or paints, inside out. From the formula to even the aerosol, valve and filling technique. Our technical ability lies in finding the optimum between all the different properties."

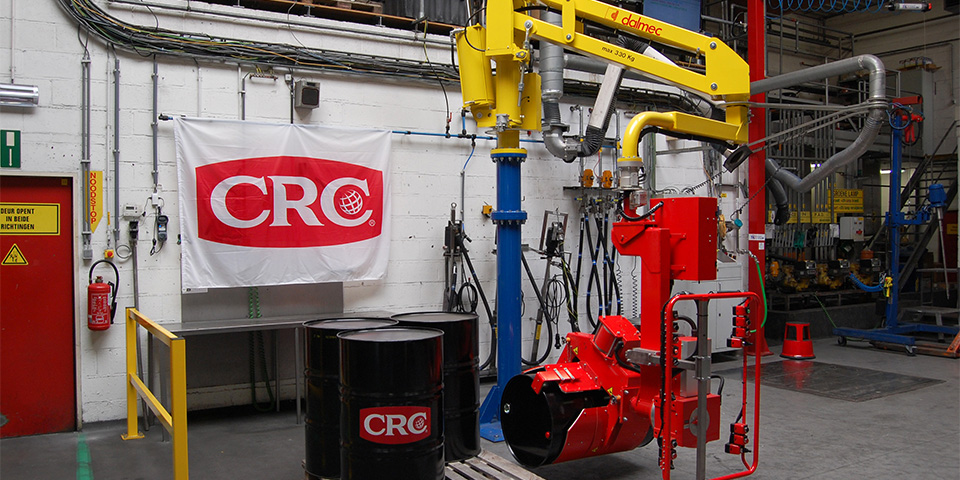

The barrel can be safely placed on the floor without damaging the gripper or the floor.

Been looking for solution for five years

In the mixing room, the magic happens. Barrels ranging from 30 to 300 kg are used. No easy task for operators to handle manually. CRC Industries had therefore been looking for a while for a way to improve safety and ergonomics. "The technical challenge was in gripping the barrel on a pallet full of other barrels and being able to put the barrel down safely without damaging the gripper or the floor," Vereecke points out. "We had been looking for a solution with sufficient ease of use for five years, but no party could take up the gauntlet. Until we were introduced to Thierry Reverse and Arcadel." CRC Industries got an idea of how Dalmec's pneumatic manipulators could make a difference through a number of videos and a demo in the showroom. Supervisor Koen Dierick, who attended demo and FAT (factory acceptance) thus also became convinced: "We had become very critical through our long search, but you could sense that Arcadel knew what they were doing and how they could meet our requirements."

Immediately embraced.

The pneumatic manipulator was built as compactly as possible to fit safely into the available space. In its resting position, the gripper even fits completely around the unit's support pole so as not to be a disturbing element. "The best proof that we needed this twenty years ago is that our people dropped their old ways of working overnight to use the manipulator. It is so easy to use and eases the work to such an extent that it is a particularly welcome addition," HSE manager Anja Van De Velde summarizes the benefits. "As prevention advisor, I found Arcadel a very fine partner to work with. They were also flawlessly able to provide the necessary safety documents. That gave enormous confidence."