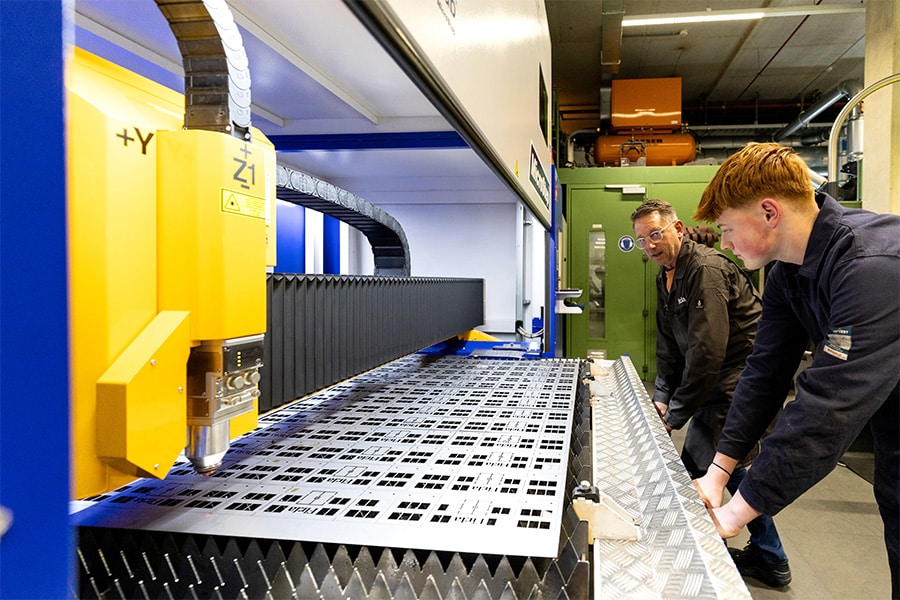

It is important that students work with the latest machinery

To ensure the best possible match between training and practice, it is of great importance that technical educational institutions use the same machines and techniques that are used in business. In order to realize this, Firda Emmeloord, a mbo institution, invests continuously in renewal of its machines, tools and systems. The latest acquisition is a state-of-the-art MicroStep MSF Compact laser cutting machine that was delivered via GT Lastechniek from Emmeloord by Wouters Cutting & Welding BV of Turnhout.

A merger of the former mbo-institutions ROC Friese Poort and Friesland College has created on August 1, 2023 under the umbrella name Firda a large-scale ROC-institution specialized in vocational education for the regions Friesland and Northern Flevoland. Many thousands of students follow vocational education at Firda in the framework of BBL and BOL. At Firda Emmeloord (about 2,000 students) a dozen courses are offered for levels 1 to 4, including for engineering Construction, Electrical and Installation Technology, Engineering and Process Technology and Mechanical Engineering and Mechatronics.

Invested in A-brands

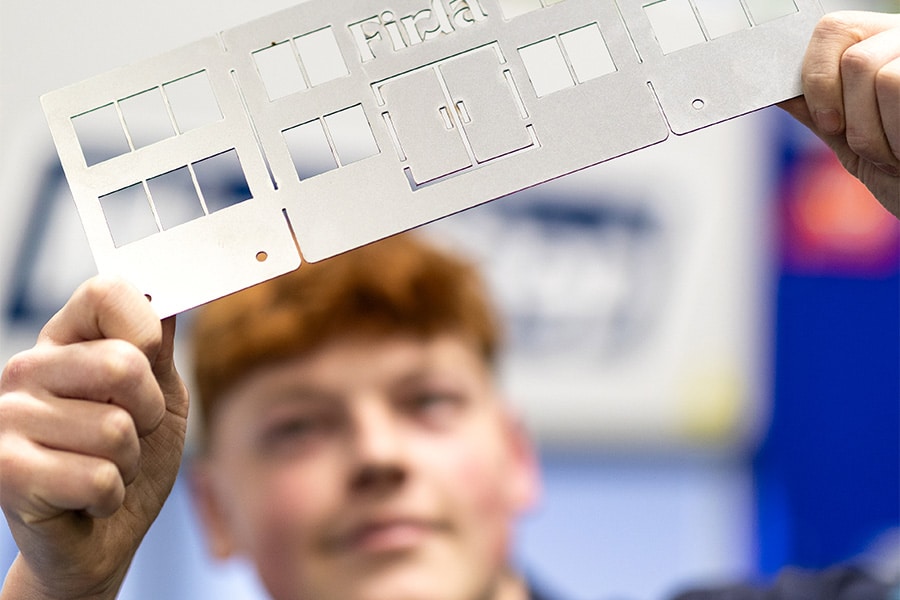

Michel Helmons, teacher of mechanical engineering, emphasizes how important it is as an educational institution to keep in touch with the business world in terms of both theory and practical knowledge and experience. 'Because students used to work with outdated machines and techniques, they had to be retrained after finishing their education before they could join the business world. That was and is different with us. We pay great attention to the connection with practice and keep our machinery not only up-to-date but also at the highest possible level. This means that we have machines and tools of only A-brands that we also encounter in contemporary companies. For example, we have the latest welding equipment and for some time now we have had a Cobot with which our students can practice robot welding. In the field of metalworking we use lathes and milling machines, both conventional and CNC, and we have various sheet metal working machines. With us, the emphasis in metalworking is mainly on construction work, while Firda Drachten in their FMT department, for example, specializes mainly in precise machining. For CNC cutting of thin sheet metal, we had a plasma cutting machine here in Emmeloord that was fine in itself, but we were very keen to exchange it for a laser cutting machine. This because of the fact that laser cutting is a much more accurate, versatile and, of course, more modern technique.'

Choice stress

The supply of (fiber) laser cutting machines is not lacking, and so we were curious as to how the engineering teachers at Firda arrived at their choice of the MicroStep machine. Helmons says: "In our region there are many metal companies. We have good contact with them, also because employees or trainees of them receive education here as part of BBL or BOL. So we also know what brands and types of machines these companies work with. Several of them have Microstep machines, so we put that brand high on our list of A-brands when we were looking for a new machine.'

MicroStep MSF Compact

Stijn Peeters, Product Specialist at Wouters Cutting & Welding BV explains how they responded to Firda's needs. 'First of all, as the name suggests, the MicroStep MSF Compact is not too big a machine. They didn't need one at Firda either. A working range of 10 meters is only interesting for companies with intensive production. This is obviously not the case with this ROC. This machine has a machining area of 2000 x 1000 mm. In addition, the MicroStep fiber laser machine is relatively easy to program and is designed for the production of high-precision parts at high cutting speeds, while offering surprisingly low maintenance and operating costs in return.

Demo machine

'As always, of course price also played a role,' Helmons emphasizes. 'Of course we also looked at other A-brands, but our preference went to MicroStep. Partly because this is a European A-brand with a Dutch-speaking service organization. A point of concern, also with other machines for that matter, was the price. We had set a budget, but everyone was way above it. Wouters, however, came up with a super solution. They had a demo machine at the factory that, partly because of its compact size, had been on display at a few trade shows. They were willing to sell it to us. The price was within our budget, so we didn't have to think long about it. Meanwhile, the machine has been there for a few months and, together with our students, we have already produced the necessary products on it without any problems'.

Machineering - booth number 172

Heeft u vragen over dit artikel, project of product?

Neem dan rechtstreeks contact op met Wouters Cutting & Welding.

Contact opnemen

Contact opnemen