Laser cutting of curved and shaped products

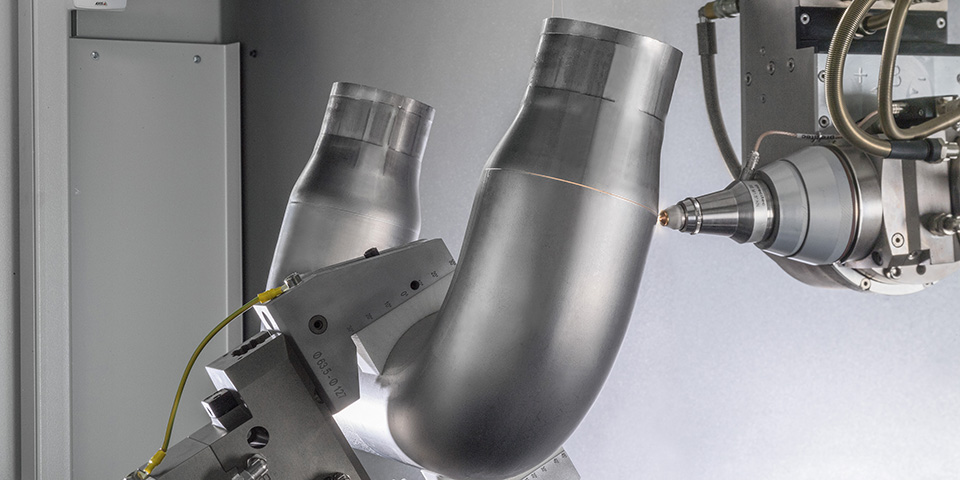

BLM GROUP introduces LT360 robotic cutting system. At Blechexpo, and earlier before that at its in-house exhibition Intube, BLM GROUP, manufacturer of tube and sheet laser cutting systems, sawing machines, bending machines and tube end processing machines, introduced a laser cutting system for bent and formed products. This LT360 is a derivative of the previously developed LT-FREE. Both systems are designed to cut 3D parts such as drawn sheet metals, hydroformed parts, bent tubes, etc.

Cutting operations in curved, drawn and formed parts occur in practice in, for example, the automotive industry (exhaust systems) and appliance construction (cooktops). In a conventional, often manual machining process, the often high tolerances are not feasible. The market therefore demands solutions that can not only guarantee high accuracy, but also greatly reduce the production time. BLM GROUP has developed a solution for this with the LT-FREE and LT360 based on a six-axis robotic arm that moves a laser head over 5 axes in space to cut 3D parts with high precision. Parts can be held by a second supporting robot or clamped onto a work or change table. Both systems operate with fiber laser sources up to 3 kW.

Laser tube family from BLM GROUP

The LT-FREE and LT360 systems are part of BLM GROUP's Lasertube family from which some characteristic features have been adopted, such as Active Piercing to control piercing and Active Focus to automatically adjust the focus position relative to the cutting nozzle. In addition, Active Gripper to control automatic part clamping devices during machining and Active Power, a measurement system that calculates the power required.

All-In-One process

For programming, BLM GROUP deploys the existing programming software system ArtCut. ArtCut is a powerful CAD/CAM system that is very easy to use and allows offline programming and simulation in a simple and intuitive way. Simulations are used to control the axis trajectory and automatically prevent collisions of the head with the part or with other machine elements. The laser technology with its active functions and database of cutting parameters, encompass over 30 years of laser cutting experience of BLM GROUP, which strongly distinguishes BLM GROUP in the field of tube processing.

Produce 24/7

The use of an automatic loading/unloading station allows for an efficient non-stop cycle, which can be used 24/7 and guarantees reliable, constant productivity.