Launch of latest software on CNC plasma models

Even the manufacturing industry does not escape digitalization. That would be a shame, because it also offers the necessary opportunities. A good example is the latest software platform that Astra-Tec offers on its plasma cutting machines. It now meticulously keeps track of all data that make cutting easier. In addition, Astra-Tec has realized some great new projects in welding automation. You can get to know them extensively at booth 1-C080 during Welding Week.

Astra-Tec has been guaranteeing innovation and expertise in the field of mechanical engineering and welding and cutting applications since 1995. A perfect combination of insight, training, creativity and technology always leads to efficient realizations for clients with an eye for quality, safety and well-being. We always keep our finger on the pulse of new developments to achieve future-proof solutions. Take the software for example. Cutting parameters, cutting time, lifespan of wear parts ... everything is now minutely and tracked automatically, so cutting can be a lot easier.

Makeover platforms

Astra-Tec also invested in a complete makeover of its current platforms to be ready for the latest plasma cutting devices. The internal software platform was updated to TwinCAT 3.0. This makes Astra-Tec's controls ready for the latest Q plasma source from Kjellberg and Hypertherm. These both use the same EtherCAT bus for control. The new software is being rolled out on all plasma driver series (SMART, HS, M and XG). Furthermore, the START series was equipped with a brand new console that protects the PC from the dust in the production environment.

At Feraxo, manufacturer of metal drums, IBC containers and coils intended for the tire and steel wire industry, a spot welding machine was commissioned for spot welding pins in metal coils.

Perfect traceability for every weld

That as far as plasma cutting is concerned. Astra-Tec has not been idle in welding automation either in recent months. It was again able to add some great references to its already impressive portfolio. Eurotruss for example, a leading and international supplier of aluminum truss systems already took its third Astra-Tec welding machine into service last month. This machine is equipped with two new CMT welding units from Fronius. All welding parameters of the weld for each product are tracked for perfect traceability.

Minimize operator time, maximize safety

A new Astra-Tec welding machine was also commissioned at Metavan Reels, a world leader in the metal coil (reel) market. Through the machine, metal flanges and cylinder are automatically welded together to form a reel. The machine minimizes operator time and ensures trouble-free changeover between different types. A high-speed door ensures a safe working environment without increasing cycle time.

Welding quality monitoring

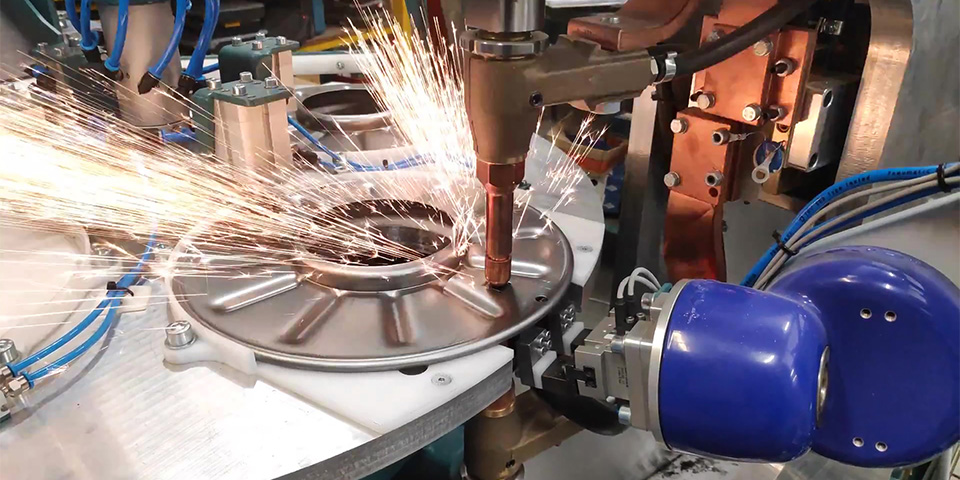

At Feraxo, manufacturer of metal drums, IBC containers and coils intended for the tire and steel wire industry, a spot welding machine was commissioned for spot welding pins in metal coils. The pins are sorted using a vision system and then inserted into the slot of a flange using a robot. The machine produces twenty finished pieces per minute. The spot welding is done with inverter technology so that the quality of the weld can be monitored.