Importance of automation continues to grow

Automation in the manufacturing industry continues, including in the metalworking sector. Manufacturers of automation solutions are not sitting still. FANUC is investing not only in the development of new products for its various divisions (Robot, CNC and Machine), but also in human resources with recruitment worldwide and in infrastructure, for example with a new building in Belgium. Thus, the specialist aims to grow with its customers in the long term by meeting their requirements.

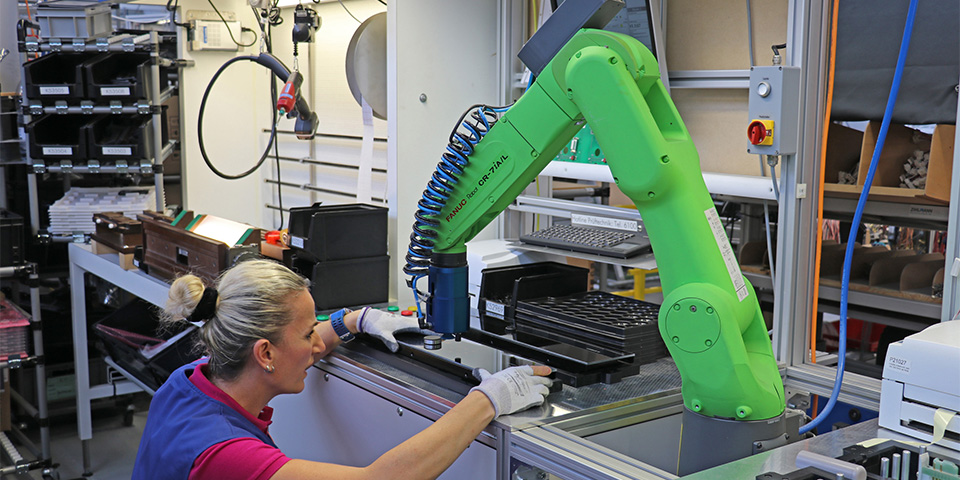

Firms are increasingly turning to automation. According to Shinichi Tanzawa, President & CEO of FANUC Europe Cooperation, there are a number of key reasons for this. First, firms across Europe want to improve the efficiency of their production to improve their international competitiveness. The use of robots is one way to reduce costs and improve quality. In addition, demographics and relocations of people in Europe have made it difficult for many companies to hire enough workers for their factories, so they are increasingly turning to machines and industrial robots. Last but not least are the expanded capabilities of robots including sensor technology, such as vision sensors and force sensors, and the increased use of collaborative robots.

New construction for FANUC Benelux and recruitment worldwide

FANUC Europe Corporation has about 220 employees at its headquarters in Echternach, Luxembourg, and another 1,300 throughout Europe. Indeed, they provide a full range of services for all European subsidiaries, including European sales and service, product support, supply chain, parts and repairs, as well as marketing, HR, IT and administrative support. "We want to grow with our customers in the long term by meeting their requirements. We are prepared for long-term investments to achieve this," FANUC Europe Corporation's President & CEO stated recently. He is referring, among other things, to the recent realization of new European FANUC branches in Milan (Italy), Rhône-Alpes (France), Malmö (Sweden) and Moscow (Russia) and the expansion of existing branches in Stuttgart, Paris, Barcelona, Wroclaw, Coventry ánd Mechelen, among others. "In early December, the foundation stone will be laid for the new FANUC Benelux building in Mechelen. The current building no longer meets the growth we have experienced in recent years, but looking at our plans to develop in the very near future, a new facility is more than welcome," explains Paul Ribus, managing director FANUC Benelux. "FANUC has recruited a lot of new employees worldwide over the past three years, including in Belgium. After the completion of our new building, our team will probably be expanded even further. With the slogan 'Service First', FANUC wants to be as close as possible to its customers, in terms of service, but equally to train customers."

Developments and advancements in all divisions

Product developments at FANUC do not stand still either. In all divisions - ROBOT, CNC and MACHINE (milling, wire EDM and injection molding) - FANUC continues to develop new intelligent software, implement new advancements and launch product expansions. In doing so, FANUC always focuses on three things: a customized solution, with a focus on the operator's ease of use and with the goal of making production even more efficient. "For example, FANUC Benelux announced another new partnership this summer. As of August, ORA Machines became the dealer for our injection molding machine ROBOSHOT," Ribus concluded. "For our machine tools ROBODRILL and ROBOCUT, we have been working successfully for years with the dealers Humacs Krabbendam and TECMO Machines."