How to get back to work safely?

The coronavirus largely brought Belgian industry to a standstill. Now that the numbers are moving back in the right direction, many companies are thinking of rebooting. Research center Flanders Make presents three new technological solutions that allow companies to protect their employees and visitors from Covid-19 contamination. Weaving machine manufacturer Picanol was very quickly actively involved, testing one of the social distancing systems at its Ypres plant.

A team of fifteen Flanders Make engineers went to work to support the VUB Lab in developing and improving a respirator and preparing it for possible production.

Flanders Make has not been idle in recent weeks and months. Behind the scenes, it has been working hard on technological solutions. Chairman of Flanders Make Ubrain Vandeurzen explains, "In response to poignant reports of acute shortages of life-saving respirators in Italy, we immediately decided to deploy our top engineers on a number of urgent trajectories in order to avoid such dramatic scenarios with us. A team of fifteen Flanders Make engineers went to work to support the VUB Lab in developing and improving a respirator and preparing it for possible production. Subsequently, Audi Brussels produced the first fifty precursor devices, which the VUB Lab is now testing and finishing. We do not want to suffocate our people literally and figuratively, and the support we receive for this from companies in the manufacturing industry in Flanders, such as Audi Brussels, gives us great pleasure."

For starters, you immediately screen everyone who comes in for body temperature with a system based on infrared readings.

Quick, easy screening

Now that many companies have restarted, Flanders Make is providing the necessary support in this as well. Specifically, this involves one device that screens body temperature and two systems that help people keep at least 1.5 m away. These solutions can be used in combination or separately, depending on the needs of the company. Flanders Make has been applying them itself for a while and is now offering them to companies. Dirk Torfs, CEO of Flanders Make: "To start with, you screen everyone who enters immediately for body temperature with our system based on infrared measurements. When in doubt, you use a thermometer and only let in those with a healthy body temperature. Large groups can be screened quickly this way, respecting social distancing. This is how you reduce the chances of sick people being present in your company.

Attention to social distancing

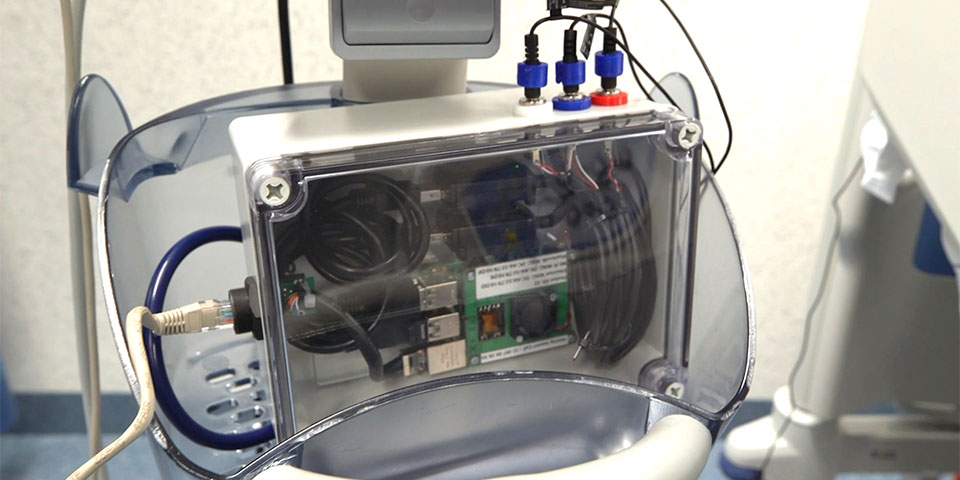

Once inside, every employee with a job that requires a lot of attention to social distancing wears a little device around the neck, which emits an audible signal as soon as someone gets too close. "This new device is therefore close to the mouth, the ideal starting point for measuring distance. This also allows operators in production to work safely. This device helps employees to immediately correct their behavior and remain attentive. In places where many people gather, such as an entrance hall or refectory, place our system with cameras, which also generates an audible signal when they get too close to each other. The camera images are not recorded and people are not recognizable in the image, so privacy legislation is perfectly respected. So it can also be used more widely, for example in the hospitality industry."

Once inside, every employee with a job that requires a great deal of attention to social distancing wears a device around the neck that sounds an audible signal as soon as someone gets too close.

Successful first tests in production at Picanol

Geert Ostyn, VP Weaving Machines at Picanol and vice president of Flanders Make: "Picanol was quickly involved in developing the social distancing devices and evaluating the technology on the shop floor. First we tested this system in Ypres with eight operators wearing the device around their necks. If they get too close, they immediately hear a signal to distance themselves. Meanwhile, it has already been expanded to eighty employees. The easy-to-install system requires no fixed infrastructure, works completely locally and respects employees' privacy. This is a great example of rapid development of a research center that can be deployed in companies in the short term." Flanders Make is currently identifying the specific needs of interested companies and consulting with potential producers of the various systems. This with a view to introducing and supporting our industry as quickly as possible.