Hardening of stainless steel to lengths of 9 m

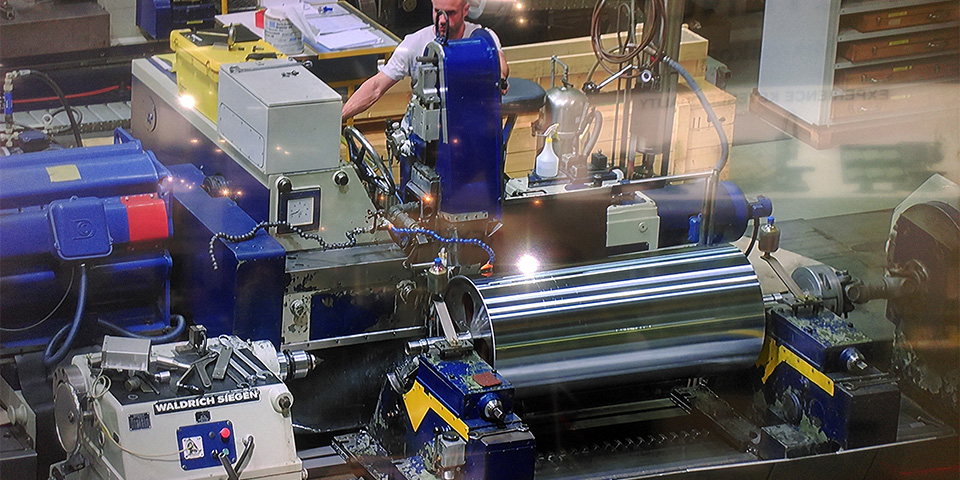

To give materials just that little extra, surface treatments are indispensable. Bel-Technologies specializes since '80 in high-tech treatments of metal for the industry. And with success. Last year, the machinery and capacity were further expanded with three new chamber furnaces. When linked together, products up to a length of 9 m can be hardened. A unique solution for corrosion-sensitive components such as pipelines and guide strips.

Bel-Technologies has been establishing itself as a competent partner in surface treatment since '80. It combines years of experience with the latest technologies to always come up with services and solutions that give clients absolute peace of mind. Managing Director Peter Van Belle: "We want to address and solve our customers' wear problems through the right technology. To keep pushing that limit, innovation is an important part of our business. Most of our coatings are patented. They help optimize the quality of your finished products and increase the productivity and profitability of your machinery, optimize durability and reduce the frequency and duration of maintenance stops." The in-house certified metallurgical laboratory, which is also available to third parties to perform damage testing and materials analysis, is the perfect capstone to that quality.

Most of Bel-Technologies' coatings are patented.

Unique combination of obtain properties

"The range of surface treatments is particularly wide with one clear goal in mind: to give your valuable technical components the right unique combination of properties," Van Belle summarizes. "For example, hard inchromizing can give a highly stressed mold part high wear resistance, increased corrosion resistance and improved temperature resistance (up to 850 °C). This technical added value greatly improves both tool life and service life while realizing great savings." You can turn to Bel-Technologies for various diffusion techniques such as inchromizing (for improved corrosion and wear resistance at high temperatures), hardening of stainless steels, aluminizing (high-temperature applications), vanadizing (wear resistance with a ceramic hardness of up to approximately 3,000 HVO,025), borizing and nickel diffusion, among others. In addition, the company is set up as a complete hardening shop to offer all heat treatments

Three new chamber ovens

The rising demand for Bel-Technologies' services is creating an unrelenting challenge in available capacities. The company therefore decided to invest in three new chamber ovens. Van Belle: "First of all, the increased capacity should allow us to serve customers even faster and more flexibly from now on. But the chosen concept also places us in a unique position in the market." Indeed, Bel-Technologies' three new chamber ovens that have been operational since last year can be linked together. This now makes it possible to treat and harden products up to a length of 9 m. Especially for pipelines and guide strips, this is a very rewarding solution for hardening up to 2,200 HV via the chromium diffusion process, in which there is much interest in the food and chemical industries.

Bel-Technologies has been specializing in high-tech metal treatments for industry since '80.

Further automating

With that, the hunger to keep innovating was by no means satisfied. Several projects were also in the pipeline this year to increase production capacity and support customers even faster and better. "With the introduction of robotics, we further automated our production again. Customer service was also expanded. In short, we want to be a modern company with modern ambitions in which the customer and his needs are always central," Van Belle concludes.