From classic wholesaler to supplier big on services

In the manufacturing industry, it is important to listen to the needs in the market and then internally weigh up whether or not to respond. Over the past decade, thyssenkrupp Materials Belgium has evolved from a pure wholesaler of stainless steel, aluminum and various types of steel to a supplier of services with greater added value for increasingly demanding customers. In addition to the classic trade with associated operations, customers can go there for the realization of integral projects or complete outsourcing from engineering over machining and assembly to even logistics.

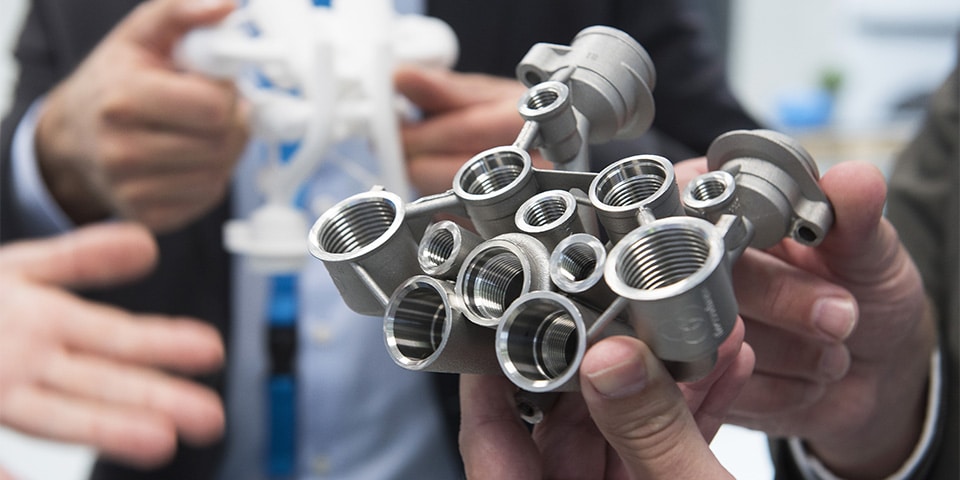

Thyssenkrupp Materials Belgium is a wholesaler of stainless steel, aluminum and various grades of steel with more than 3,000 loyal customers in the Belgian metal industry. "Although that distribution still remains our core business, a lot has changed in recent years. Indeed, at the request of our customers, we have started performing all kinds of operations, such as 2D and 3D laser cutting, bending and sawing, but also blasting, drilling, decoiling, slitting, grinding, brushing and water cutting. To this end, we have a production facility with more than twenty machines and work together with external processors specializing in galvanizing, anodizing, coating and milling," says project manager Marc Polfliet. "Thanks to a team of specialists, we can completely unburden customers. This commercial team combines technical knowledge with experience in project management to analyze, improve and manage projects. We provide technical support in terms of material selection or design, calculation, stock management, taking care of all kinds of documents, even selecting specific packaging, marking and logistical processing. This allows the customer to fully focus on their core business."

Thyssenkrupp Materials Belgium is more than a wholesaler. The company provides numerous machining services and even has a team of specialists, which takes care of customers completely. (Image: Gorodenkoff Productions OU)

Differentiating through added value

The combination of trader, processor and constructor is quite unique. Thanks to this added value, thyssenkrupp Materials Belgium distinguishes itself in Belgium, but also in other countries within and outside Europe. Production takes place in Belgium, in Europe, even worldwide and is optimally adapted to the expected costs, deadlines and services. The international presence of thyssenkrupp with its own employees and equipment is an important added value in this respect. For example, one of the fastest growing spearheads is the site in Eastern Europe, where brand new prototypes are constructed and long-running productions are developed. "Internal and external audits, drawing up quality procedures, in-house engineering, CAD support ... it is all part of the process to finally arrive at series production. We are called in for the most diverse projects. For example, customers ask us to optimize existing products in terms of design and functionality in close consultation. In some cases, we receive technical drawings that we have to finalize ourselves in order to finally produce the fine-tuned pieces," Polfliet explains. "We have carried out quite a few projects in the meantime, for example for the supply of bumpers in stainless steel, for which we purchase the material, process the pieces and draw up and implement an optimal delivery plan. Transport cases for gas cylinders are also made at thyssenkrupp Materials Belgium. We look at the needs in the different countries and adapt those metal frames according to local requirements." Meanwhile, the importance of added value continues to grow. Thyssenkrupp Materials Belgium started this department with two people and today there are thirteen of them.

Thyssenkrupp Materials Belgum is responsible for the complete elaboration of the most diverse projects. Internal and external audits, drawing up quality procedures, in-house engineering, CAD support ... it is all part of the process to finally arrive at series production.