Fast, smart and efficient order picking

Efficiency is the key to low logistics costs. Order picking is hugely important in this regard, because that's where you can save a lot of time and money. Automated warehouse solutions, such as platform elevators or warehouse elevators, are an ideal solution for this. DDD Technics specializes in the sale and after-sales service of such systems. Indeed, since mid-2015, the Stekene-based company has been the official partner of market leader Hänel Büro- & Lagersysteme from Bad Friedrichshall, Germany.

In 1957, Gerhard Hänel started manufacturing filing elevators according to the paternoster principle. His family business Hänel Büro- & Lagersysteme has grown into a specialist in automated warehouse solutions with three production facilities and representations in more than sixty countries worldwide. "We have been the official dealer for Belgium of this market leader in automated storage systems since mid-2015. Every day, fifteen people are responsible for the sale, installation, commissioning and after-sales service of platform elevators, warehouse elevators or carousel systems and the corresponding control systems," says Dirk De Decker, Managing Director of DDD Technics. "Each project starts with a meeting at the customer's premises. Based on his needs, we design a suitable customized solution. Some 3,000 systems are now active in Belgium in the most diverse applications: pharmacies, hospitals, offices, metal processing companies and many other industrial branches." DDD Technics is known for its large stock of used warehouse elevators and paternoster cabinets and

also supports its customers in the move or sale, maintenance or repair of existing dynamic systems, with 24/7 service.

Hänel Rotomat® and Lean-Lift®

Those who want to optimize their intralogistics concept can choose from a variety of systems at DDD Technics and Hänel. For example, the Rotomat® warehouse elevator and the Lean-Lift® platform elevator system maximum use of the available height of the room up to 18 m and components are stored optimized without loss of space in height. Depending on the application, systems of different sizes and weights are possible. "The Hänel Rotomat® includes carrier sets matched to the size and weight of the goods and is available in several models with standard widths of 3,270 or 3,420 mm and different depths, good for a payload per carrier set between 150 and 750 kg and between 3,000 and 14,000 kg for the entire system," De Decker explains. "The Lean-Lift® is the logical addition to the proven Rotomat® principle and exists in models from 840 to 4,460 mm wide, with a choice of four different depths: 635, 825, 1,047 and 1,270 mm for storing goods with weights ranging from 300 to 1,000 kg per tray and a maximum payload per system of 60,000 kg. The stored articles are kept in plateaus optimized in terms of height." Both systems automatically bring the retrieved article to the work opening within seconds, where it can be taken out at an ergonomic height by the operator. They can be used as stand-alone units, but the warehouse can also be enlarged incrementally with more modules, at the Lean-Lift® even combined over several floors.

The Lean-Lift® platform lift system makes maximum use of the available height of the space. It automatically brings the retrieved item to the work opening within seconds.

Smart control concept

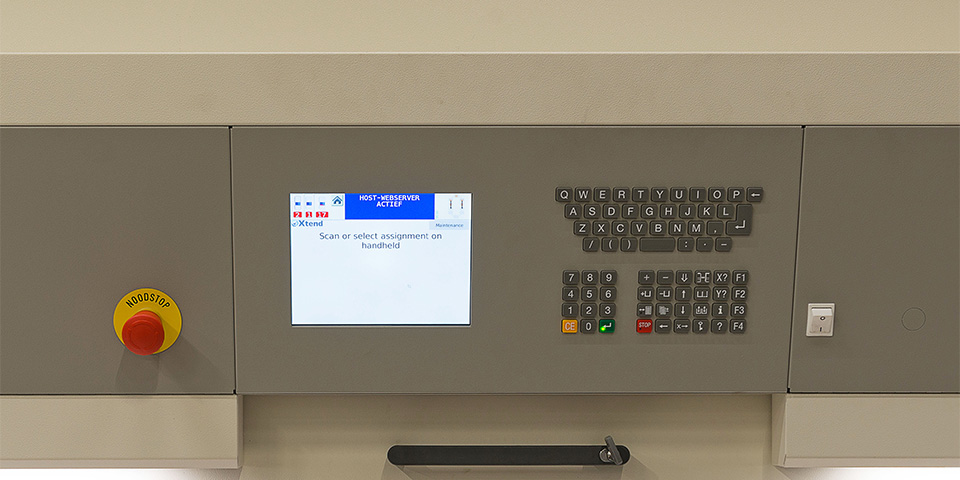

Hänel responds perfectly to growing digitalization. The four different modes in the elevator controls allow simple and individual networking. Thanks to the SOAP web service interface, no middleware is also required between the controller and the ERP package. "The MP 14 N is our newest controller," De Decker concludes. "On a 12" touchscreen, the operator gets a clear overview of the warehouse situation thanks to the graphical representation of the occupancy and article master data can be displayed in a lightbox." Customers can further expand their system with the software package HänelSoft® and linking with Augmented-Reality and Pick-by-Voice.

The Hänel systems are equipped with elevator controls, which can be very easily networked. The MP 14 N with 12" touch screen and clear graphic display is the latest development.