ERP package brings insight into production

We have those well-kept secrets in our Belgian industry. Did you know that Teksam Company of Genk is a world player in fast-displacement masts? It makes the difference by focusing on quality and competitive delivery times. Insight into production is indispensable for this. TeksamCo recently started relying on Ridder iQ, Trivest Software Group's ERP package for the manufacturing industry, for this purpose. "We have gone from an old-fashioned way of working to supersonic. Unbelievable how much insight we gained from it," summarizes Serge Do Ceu, Director of Finance & Administration.

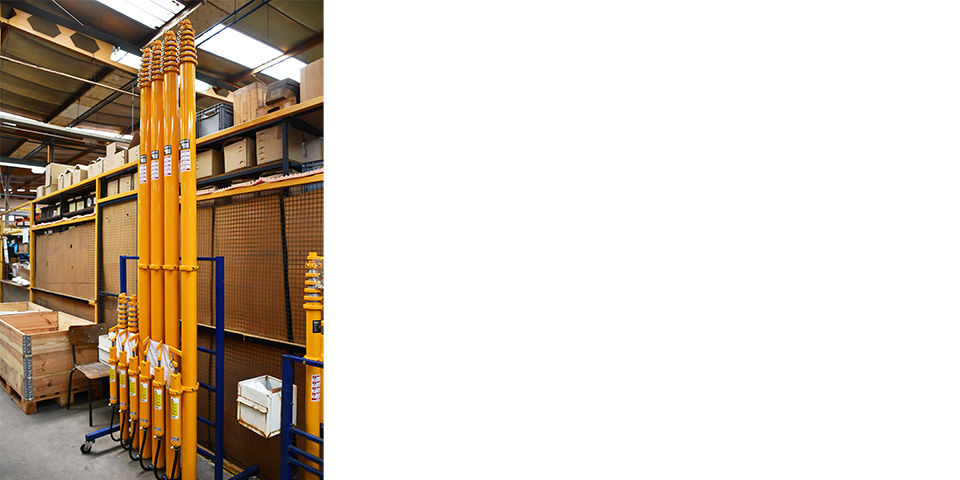

TeksamCo specializes in mobile, fast-extending masts divided into three brands. Teklite serves for lighting and surveillance and ends up on fire department intervention vehicles, for example. It ranges from simple manual systems to far-reaching electric mast systems with remote control. Secondly, there is Clark Masts, a pioneer in fast mast systems used for telecommunications, measurements and surveillance. TekMast, in turn, focuses on sectional masts that have excellent resistance to harsh conditions and military approval. "Only 2% of what we produce is destined for the Belgian market, the remaining 98% finds a market all over the world." However, that also means that TeksamCo faces global competition. "So you have to be able to deliver quickly. Delivery times of four to six weeks have become the rule. In addition, we make a difference by also completely adapting standard products to a customer's needs. If a customer asks, we will think and develop with him."

Serge Do Ceu: "The resistance to the change has since subsided because everyone is now discovering the benefits it brings to them. Now we can continue to grow step by step."

Flexible and user-friendly

To continue to excel in this, Do Ceu wanted more insight into production. "The production floor was basically a blind spot. Orders went in, but you didn't have an overview again until the product was ready. Moreover, that brought a huge paperwork burden. We were too dependent on documents. If we wanted to grow further, we had to address this and evolve into modern business operations." An ERP package was to provide solace. After comparing demos from different manufacturers, TeksamCo resolutely chose Ridder iQ from Trivest Software Group. "Not only was it written in the latest electronic language, it also felt very flexible and user-friendly. I knew right away that the consultant would be able to think with me to really give us the solution we needed. I didn't have to bend my production program to the ERP program, it went the other way around. You could conjure something formidable out of it."

With a few clicks, operators know what to do and at the same time our sales people have insight into how far along the order is in production

Understanding production

TeksamCo set the bar high right away. Last year, implementation began with several modules at once. "Not the easiest path," admits Do Ceu. "But the necessary one to get insights quickly. More than a hundred different operations happen in-house to finish the masts, from turning and milling, to welding, bending and cutting, assembly and even plastic and rubber vulcanization for our own seals. One of the most important improvements was the integration of the "vault. This is where the drawings, with all the details, are kept and linked with our engineering department. So all the information is available digitally. Away with all the papers! In our production there are now touch screens. With a few clicks the operators know what to do and at the same time our sales people have insight into how far the order is in production. Incredible how much information you can get out of it. That's an incredible win."

TeksamCo specializes in mobile, fast-extending masts divided into three brands.

Towards state-of-the-art business operations

According to Do Ceu, the time savings that this already provides will become even greater when the estimating and planning modules also follow suit. "You can then start playing with parameters to see what is the best possible way to complete orders within the desired time. Do we need an extra shift? Does someone need to be added to a machine? Do we ask our workers to work overtime? The possibilities are many. In one year, we went from an old-fashioned operation to state-of-the-art. That took a lot of patience from our 50 employees. The resistance to the change has since subsided because everyone is now discovering the benefits it brings to them. Now we can continue to grow step by step."