Produce more efficiently and collaborate more intelligently

EMO 2025 focuses on innovation, connectivity, automation and AI

To remain at the forefront globally, European industry faces major challenges. Older machines will have to be replaced by state-of-the-art production equipment, while the growing shortage of experienced workers requires faster introduction of smart automation. At the same time, more intelligent collaboration in the chain, more attention must be paid to the circular economy, while the use of scarce raw materials but also the CO2 footprint must be reduced. To achieve this, investments must be made on several fronts for which the upcoming EMO in Hannover (Sept. 22-26) is an ideal source of inspiration. The theme of this year's fair is 'Innovative Manufacturing', with over 1,400 exhibitors in 17 halls presenting inspiring solutions with which our metal industry can strengthen its international competitive position.

It is crucial that the metal sector continues to embrace new technologies and solutions. To that end, at EMO you will find a wide selection of leading manufacturers and suppliers who specialize in customized production solutions in mechanical engineering. At the booths, you can see machine tools in action, exchange ideas with industry specialists, as well as seek targeted advice and attend workshops and live demonstrations.

50 years of EMO

This year marks the 50th anniversary of the EMO! The first fair was in Paris in 1975 and switched between Paris, Milan and Hanover in the following years. In 2023 and this year the fair was/is in Hanover and in 2027 it will be in Milan again. "EMO is unique among trade fairs because it presents the entire value chain of metalworking - from machine tools, production systems and additive processes to precision tools, automation, metrology, quality assurance, software and accessories," stressed Dr. Markus Heering, executive director of EMO organizer VDW (German Association of Machine Tool Manufacturers) in his presentation at the 'EMO World Tour' meeting in mid-May this year in Rotterdam. "The motto of EMO, 'Innovate Manufacturing,' is therefore more than just a slogan. It is a call to suppliers and users to courageously embrace the opportunities offered by new technologies."

Total Solutions

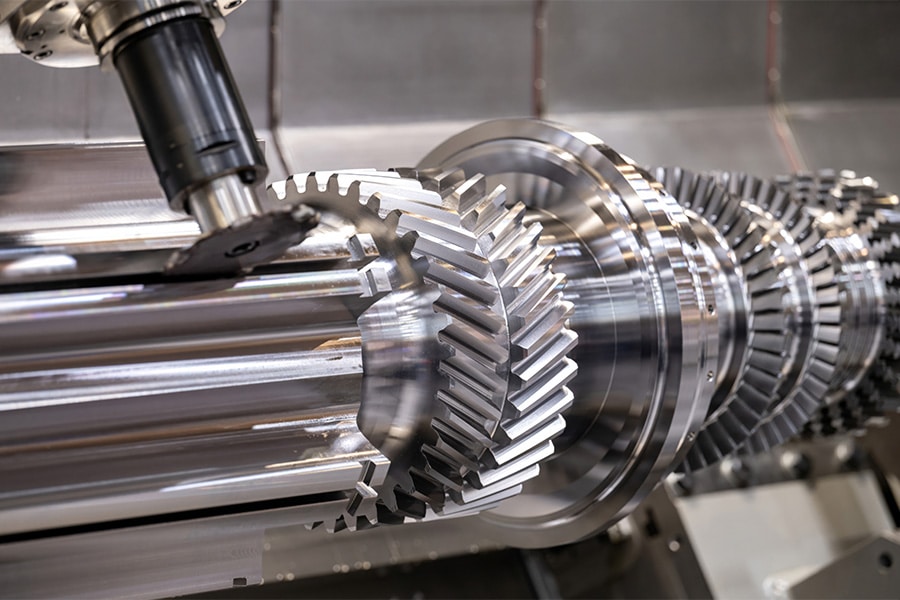

"While the focus in the early years of EMO was more on individual machines, now it is mainly about smart and cost-effective total solutions," said Christian Pfeiffer, senior vice president of sales at Deutsche Messe AG. "There is now a completely different communication situation, where all machines in the process chain can be linked together. This can be seen live at the EMO. Also, machines today are equipped as standard with comprehensive sensor and monitoring systems that enable data-controlled man-powered and unmanned production. But not only that. Suppliers can "watch" remotely, see failures coming and prevent them, and schedule maintenance based on actual condition. This is not only cheaper, but also means less downtime, increasing machine efficiency. In addition, machine learning, a subfield of artificial intelligence, opens up a new dimension of self-organized production. This allows companies to respond more flexibly to changes in the market and to individual customer needs, which is a crucial prerequisite for remaining innovative and competitive in the long term."

Changing market

In terms of staffing, the industry is facing both a changing work ethic (advance of 3-day work week) and a growing shortage of skilled workers. Both phenomena can be countered by digitalization and automation. Interactive assistance systems can support machine operators and increase productivity, quality and efficiency. At the same time, rare resources and energy will have to be used more sparingly, and even more attention will have to be paid to the circular economy. Waste streams will also have to be contained, recycling encouraged and machines made more energy efficient. All of this will be covered in the "Sustainability Area," which will be a focal point at the upcoming EMO and showcases current solutions aimed at sustainable production.

Connected factory EN

Also present during the EMO World Tour in Rotterdam were Eddo Cammeraat (chairman FPT-Vimag), Ires Veerman (branch manager FPT & Nevat - FME) and John Kooning (managing director DMG Mori Netherlands). They emphasized that in this changing market, companies must become more adaptive and flexible and, above all, focus more on cooperation. A good example of this was given by six companies in the spring during the TechDemoweek in Veenendaal/Ede. "The ERP systems of all participating companies were connected and together they produced a personalized end product," says Veerman about this. "With a more extensive configuration, we will be at the EMO in Hannover in September, where a consortium of eleven leading technology companies united by FPT will show in Hall 15 how the machining factory of the future is within reach."

Fully functioning factory at the fair

At the joint EMO booth of Cellro, DMG MORI, FUCHS, HEIDENHAIN, ISCAR, Mitutoyo, MKG, SCHUNK, Supplydrive and TopSolid & Zoller (Lowland) visitors will experience a fully functioning factory with three essential elements: Digital Work Preparation, Autonomous CNC Production and Real-time Production Cockpit. This fully integrated production environment minimizes machine downtime, increases efficiency, shortens lead times, reduces CO2 output and also complies with the latest regulations (PCF, e-invoicing, digital product passports).