Efficient post-processing of 3D printed parts

Until recently, the post-processing of 3D printed parts was one of the factors slowing down the industrial application of additive manufacturing. AM Solutions, the Rösler Group's brand name for all additive manufacturing activities, provides solutions for the automated post-processing of metal and plastic parts. Together with HP, the specialist is now also developing technology for automated post-processing of parts just realized by HP 3D printers.

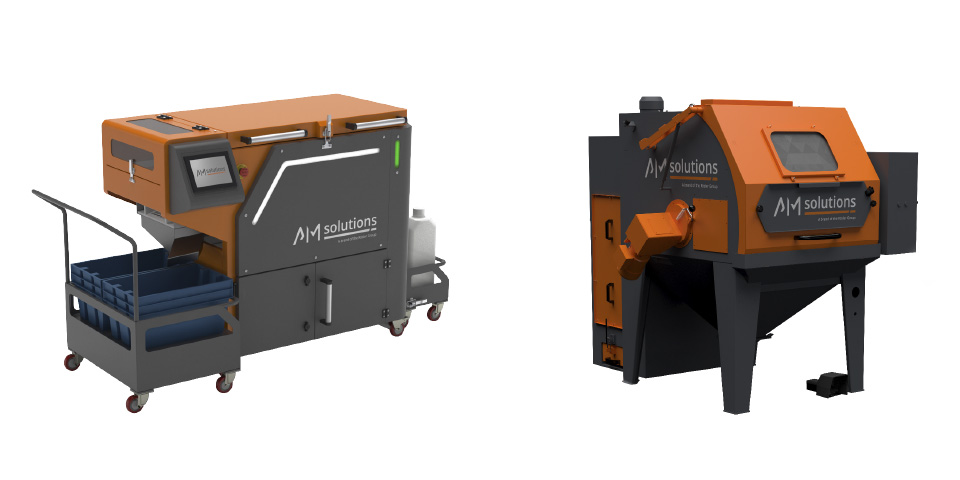

At Formnext, the S and M lines were expanded to include S1 Basic and M1 Basic, two compact entry-level models that can be easily integrated into any production line.

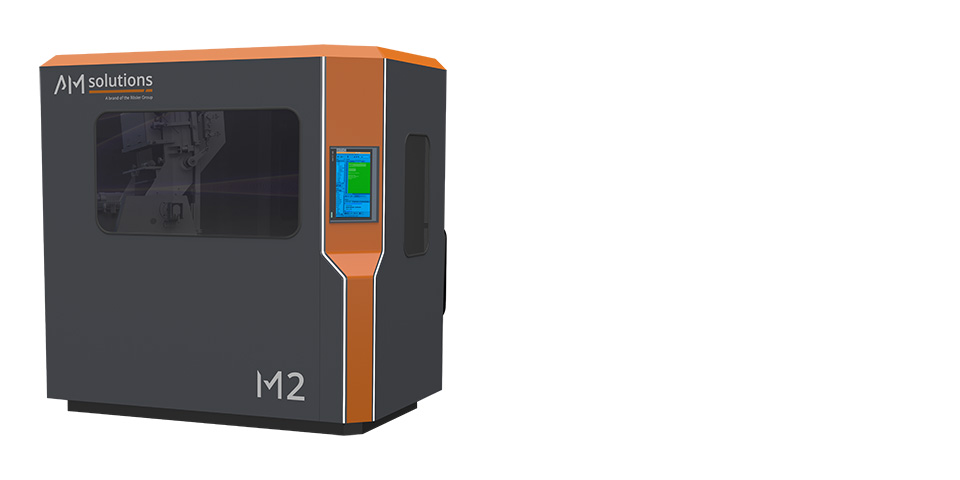

To support customers in implementing additive manufacturing, AM Solutions recently launched a 3D printing service company, where customers can go for the entire process, from design and engineering for additive manufacturing to 3D printing itself and all forms of post-processing, including heat treatment and CNC milling. This also includes reverse engineering, where existing parts are digitized by 3D scanning for subsequent printing. AM Solutions has several 3D printing technologies for metal and plastic in-house, including HP's Multi Jet Fusion 5200 3D printer. Indeed, during Formnext, the two companies announced a collaboration. "HP is an important partner and this cooperation allows us to optimally align automated post-processing solutions with their Multi Jet Fusion technology," said Stephan Rösler, managing director Rösler Oberflächentechnik. "We offer a wide range of solutions for automated post-processing of 3D printed workpieces. For example, there are systems for both plastic and metal products; and both for automatic powder removal, print cleaning, surface enhancement as well as staining of 3D printed workpieces." These solutions not only reduce the amount of manual labor, but also optimize the properties of 3D printed parts. In addition to optical improvements, mechanical properties often improve. For example, the M2 machine automatically reduces the surface roughness of a metal AM workpiece to Ra 0.062 µm. The original geometry is maintained, while the high-gloss finish improves the part's properties.

The M1 is ideal for finishing single pieces and small batches, the M2 for large volumes.

Powder removal, cleaning and surface improvement

AM Solutions' range today includes eight machines, complemented by machines from partners with whom it works intensively. The S-line consists of four machines to automatically remove powder and clean the surface of the AM workpiece with blasting technology to clean, while the M-line includes machines for surface finishing of pieces based on Rösler's slide grinding technology. "With our plug-and-play S1, we remove powder - manually or semi-automatically - and clean the surface. At Formnext, we presented the S2, with which parts printed on a powder bed machine can be automatically extracted and cleaned. The removed powder can be reused on the next job. The compact S3, which can be loaded with a robot, was developed for finishing large and complex parts. The water-based process for removing support structures and excess powder results in consistent and repeatable results," explains Rösler. "The M1 is ideal for finishing single pieces and small batches, the M2 for large volumes. Automatic process monitoring of all relevant parameters ensures high process stability. Finally, our M3 is used for slide grinding and polishing of large, complex AM workpieces." At Formnext, the S and M lines were expanded to include S1 Basic and M1 Basic, two entry-level models that can be easily integrated into any production line due to their compact design.

At Formnext, AM Solutions presented the S2, which allows automated unpacking and cleaning of parts printed on a powder bed machine.

Colors of plastic parts

AM Solutions cooperates with specialists in the field of post-processing of AM workpieces, for example with Post Proces Technologies, a pioneer in post-processing of SLA, FDM as well as MJF and Polyjet printed parts, and DLyte, which builds systems for post-processing metal parts. With these, internal structures previously inaccessible can be smoothed. With its Cypress technology, AM Solutions also offers a solution to color 3D printed nylon parts. AM Solutions (booth 4155) and Rösler Benelux BV (booth 4156) are participating in MNE & Prototyping 2020.

Heeft u vragen over dit artikel, project of product?

Neem dan rechtstreeks contact op met Rösler Benelux BV.

Contact opnemen

Contact opnemen